What Is The Best Temperature To Pour Soy Wax Melts?

Soy wax melts are a popular candlemaking project that involves pouring melted soy wax into silicone molds to create wax cubes or shapes. When heated, the melts release fragrance to scent a room. Proper pouring temperature is crucial for getting the best results from soy wax melts.

This article will provide an overview of soy wax melts, discuss the factors that determine ideal pouring temperatures, give recommended temperature ranges, and offer tips for achieving the right temperature, testing pours, storing melts, remelting, and safety. Understanding proper soy wax melt pouring technique helps ensure the wax cubes release fragrance evenly and have a smooth finish.

What Are Soy Wax Melts?

Soy wax melts are blocks of soy wax infused with fragrance. They are wickless candles that provide aroma but do not require a flame. To use soy wax melts, simply place a block in a wax warmer, tart burner, or electric wax melter, allowing the wax to melt slowly and release its aroma. The wax never burns, it just gently melts and liquefies. As it does so, the fragrance oil in the wax is emitted as a vapor to scent a room or space.

Soy wax melts are often preferred over paraffin wax melts because soy wax melts are made from natural soybean oil, while paraffin is a byproduct of petroleum refining. The natural soy wax is biodegradable and renewable. Soy wax also blends well with essential oils and fragrance oils. It helps anchor scents and provides an even, consistent release of aroma from the wax melt.

Additionally, soy wax melts are very customizable. You can purchase premade melts in many fragrances, or make your own melts at home. Soy wax is easy to melt and pour yourself using molds. This allows you to create personalized scents and wax melt shapes. Overall, soy wax melts provide a flexible, natural way to scent your home.

Factors That Affect Pour Temperature

There are several key factors that determine the ideal temperature to pour soy wax melts at, including:

Wax Additives

Adding fragrance oils, dye, or other additives to soy wax can alter its melting point. Fragrance oils in particular tend to lower the melting point, so a slightly higher pour temperature may be needed. According to candlescience.com, pouring soy wax 10-15°F above the melting point allows enough temperature cushion when adding fragrance.

Desired Texture

The pour temperature affects the final texture and appearance of the wax melts. A higher pour temperature around 185°F produces a smooth, glossy top, while lower temperatures like 160°F result in a more matte finish. The optimal texture is a personal preference.

Container Material

The material of the container holding the wax can pull heat away at different rates. Glass and metal containers conduct heat faster than plastic or silicone. Pouring at slightly higher temperatures helps account for faster cooling in non-insulating containers.

Recommended Pour Temperatures

The recommended pour temperature range for basic soy wax is 185-190°F (85-88°C) according to CandleScience.com. This temperature allows the wax to flow smoothly into molds or containers without being too hot.

Additives like fragrance oils, dye blocks, or vybar can alter the ideal pour temp. Fragrances may cause wax to accelerate or set up more quickly, so a slightly higher temp of 190-195°F (88-91°C) is suggested. Vybar and other additives also warrant a 5-10 degree increase. Refer to manufacturer guidelines for any additives.

Take care not to overheat soy wax. Temperatures above 195°F (91°C) can scorch the wax, resulting in discoloration and impaired performance according to LiveMoor. Keep the wax just hot enough to flow smoothly for best results.

Achieving the Correct Temperature

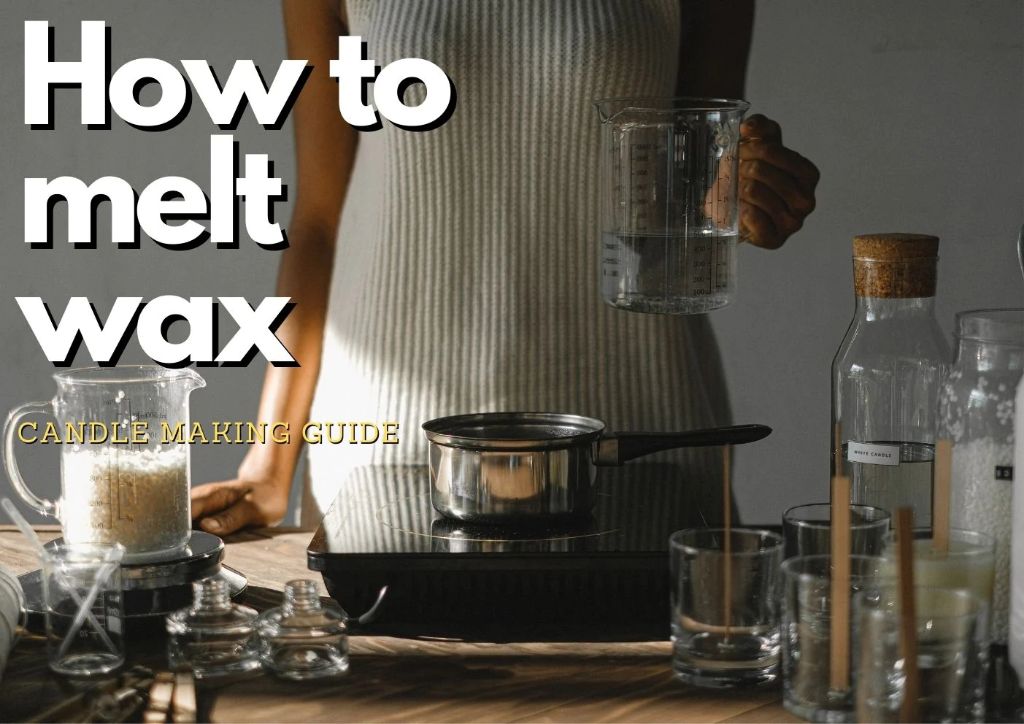

When heating soy wax for melts, it’s important to achieve an optimal pour temperature to ensure proper melt quality. There are a few key methods for reaching the ideal temperature:

- Use a double boiler or makeshift double boiler setup. This involves placing your soy wax container over a pot of simmering water to provide indirect, even heating. Direct stovetop heat can scorch the wax or make temperature control difficult (Source).

- Use a thermometer to monitor the temperature. Soy wax should be heated to 80-85°C/176-185°F for ideal pouring. Digital thermometers make it easy to track the temperature (Source).

- Avoid overheating the wax. Temperatures over 90°C/200°F can discolor the wax and reduce performance. If the wax starts smoking, remove from heat immediately.

Taking the time to properly melt the wax at the right temperature will ensure your homemade soy melts turn out their absolute best.

Testing Your Pour

Once your soy wax melts have fully cooled and hardened, it’s important to test the pour before packaging or selling them. Here are some key things to look for:

Check the texture – Properly poured soy wax melts should be smooth and have an opaque, frosty appearance. They should be firm but not brittle. If the melts are too soft, grainy, or have an oily sheen, the wax was likely poured at too low of a temperature. Refer to the troubleshooting tips below.

Confirm full scent throw – Soy wax holds fragrance oils well, so your melts should have a strong aroma. If the scent seems weak, try using a higher concentration of fragrance oil next time. You can also test scent throw by melting a cube – the room should fill with fragrance once melted.

Troubleshooting:

- Grainy or crumbly texture – Wax was poured too cool, try a few degrees warmer next time. Make sure to stir thoroughly and pour quickly. Let harden completely before handling.

- Wet, soft, or sticky melts – Wax poured too hot, aim for 5-10 degrees cooler on your thermometer. Overheating the wax can also reduce scent throw.

- White spots or discoloration – Can occur if wax cooled too quickly or unevenly. Try smaller pour amounts or insulating the mold. Stirring constantly as it cools also helps.

- Weak fragrance – Use a higher concentration of oils, up to 1 oz per pound of wax. Making melts in silicone molds versus clamshells can also boost scent throw.

If your soy wax melts don’t turn out as expected, don’t give up! It can take some trial and error to achieve the ideal pour. Adjusting the temperature and pour method can make all the difference.

Storing Melts After Pouring

After pouring soy wax melts into molds, they should be allowed to fully cool and harden before removing them from the molds. This usually takes 6-12 hours depending on the size of the melts and ambient temperature. It’s important not to rush the cooling process, as removing melts too soon can cause them to become misshapen or damaged.

Once cooled and hardened, soy wax melts need additional time for the scent to properly set during the curing process. This allows the fragrance oils to fully bind with the wax. Soy wax melts typically require 1-2 weeks curing time before use. During this period, the melts should be stored in a dry, room temperature area away from direct light and heat sources.

The best storage containers for cured soy wax melts are resealable plastic clamshells or bags. Glass jars can also be used. This keeps the melts protected and contained while allowing the fragrance to be retained. Containers should be clearly labeled with the scent and pour date. Stored properly in a cool, dry place, soy wax melts can last 9-12 months before losing noticeable fragrance and effectiveness.

Sources:

https://www.purcellandwoodcock.com/blog/how-long-do-wax-melts-last.html

https://www.shearer-candles.com/en-us/blogs/blog/how-to-use-wax-melts-guide

Remelting and Repouring

Sometimes you may need to remelt and repour your soy wax melts if you notice issues with the finished product. Common reasons for needing to remelt and repour include:

- Scent is not strong enough

- Appearance is uneven or full of air bubbles

- Hardness is too soft or too brittle

- Melts are too thick or thin

The key when remelting soy wax is to avoid overheating. According to Livemoor, soy wax should be remelted at the lowest temperature possible, around 158-176°F (70-80°C). Excessive heat can burn off fragrance oils and alter wax properties. Remelting too hot or too frequently can also make the wax more brittle.

When adding additional fragrance oil, only use up to 1% by weight at remelt to avoid seepage issues. Gently stir in any additives to evenly distribute without creating air bubbles. Then repour melts as soon as wax reaches proper temperature. Let melts fully cure 24-48 hours before attempting to remelt again.

Safety Tips

When working with hot wax, it’s important to take proper safety precautions to avoid burns or breathing in wax fumes. Here are some tips for pouring soy wax safely:

Ensure proper ventilation when pouring hot wax. Open windows, use a fan, or pour wax in a well-ventilated area. Breathing in wax vapors can cause respiratory irritation, so avoid leaning directly over wax as you pour (Wax Melts Safety Guidelines – all you need to know).

Wear protective gear like oven mitts, long sleeves, closed toe shoes, and safety goggles. Molten wax can cause severe burns if it splashes exposed skin. Be careful when handling anything containing hot wax.

Allow wax melters, warmers, and poured wax to fully cool before touching. Never handle hot wax containers or electronics with bare hands. Check temperature before adding more wax to melters.

Keep children and pets away from pouring area. Supervise children around melted wax and instruct them not to touch wax warmers.

Never leave melting wax or warmers unattended. Turn warmers off when not in use. Douse any wax fires with baking soda rather than water (Wax Melts Safety – Everything You Need to Know).

Store melted wax in heat safe containers on a stable, heat-resistant surface. Place in an out-of-reach area when cooling.

Conclusion

When pouring soy wax melts, the optimal temperature range is between 175-185°F. Pouring in this range allows the wax to fully melt and pool nicely in the melt container without getting too thin. It also enables effective scent throw once the wax melt is lit. Proper pouring is key to achieving strongly scented, neatly formed wax melts that retain their shape.

The main benefits of pouring soy wax melts at the right temperature are:

- The wax fully melts and pools smoothly, creating an even surface.

- The melts retain their shape without becoming misshapen as they cool and harden.

- The wax adheres properly to the melt container walls.

- The fragrance oils are not burned off, allowing optimal scent diffusion.

- The wax and fragrance have time to properly blend together.

Taking care to pour soy wax melts within the ideal 175-185°F range will ensure you end up with perfectly scented, neatly formed melts every time.