What Is Bath And Body Candle Wax Made Of?

Bath and body candles are a type of candle formulated using ingredients to provide benefits beyond just scent when burning. Unlike regular candles that just emit fragrance, bath and body candles can moisturize skin, provide aromatherapy benefits, and more. The wax used in bath and body candles plays a key role in delivering these extra perks.

There are several different types of waxes that can be used to make bath and body candles. The wax provides the structure and shape for the candle, holds the fragrance oil, and facilitates even and complete burning. Common waxes include paraffin, beeswax, soy wax, palm wax, coconut wax, and gel wax. Each wax has its own unique properties that impact the candle’s look, scent throw, burning ability, and more.

The purpose of candle wax is to fuel the candle while also allowing fragrance to be dispersed when lit. The type of wax impacts important candle qualities like the melt point, surface texture, ability to hold fragrance, and burning performance. Choosing the right wax for bath and body candles is crucial to achieve the desired aroma therapeutic benefits and sensory experience.

Paraffin Wax

Paraffin wax is the most common type of candle wax. It is derived from petroleum and is a byproduct of oil refining. Paraffin wax is relatively inexpensive to produce, which makes it an affordable option for candle making. The texture of paraffin wax is hard and opaque. It has a high melting point, which allows it to retain its shape as the candle burns. The hardness of paraffin wax also makes it easy to mold into candle shapes and designs.

However, paraffin wax does produce more soot than natural waxes when burned. The soot can result in residue on wicks and jar interiors. Paraffin wax candles also tend to burn quicker than other wax varieties. While inexpensive, some consumers prefer to avoid paraffin candles due to the petroleum-derived source of the wax.

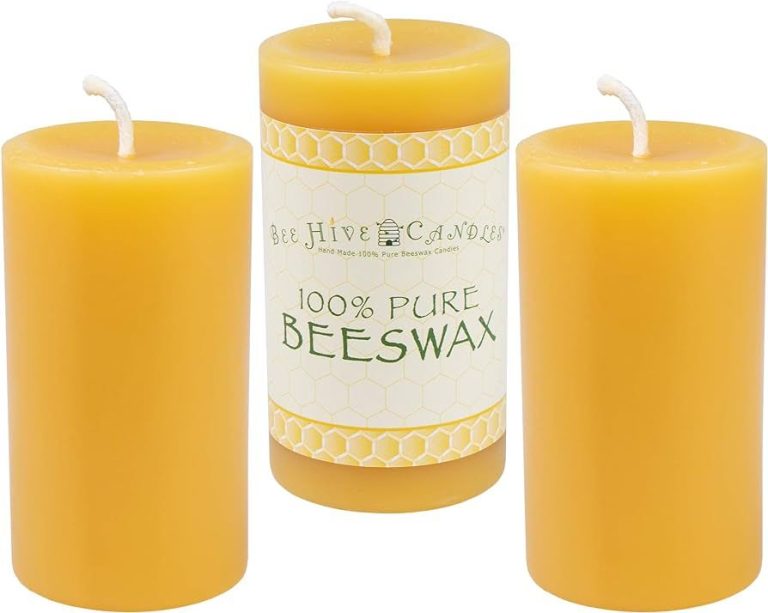

Beeswax

One of the key components in bath and body candle wax is beeswax. Beeswax is a natural wax produced by honey bees. It is made from the honeycomb that bees create in bee hives. The honeycomb consists of hexagonal cells that contain eggs, larvae, honey, and pollen. To produce beeswax, beekeepers collect the honeycomb and melt it down. The wax separates from the other materials and rises to the top, while the impurities sink to the bottom. The wax is then filtered and molded into blocks of beeswax.

Beeswax has been used for centuries in candle making, cosmetics, medicinal ointments, and for sealing and preserving things. It has a lovely honey-like scent and a soft, pliable texture. Beeswax by itself has a low melting point and burns relatively quickly, so it is often blended with other harder waxes. But it is prized for its natural, non-toxic properties. Beeswax is hypoallergenic and contains vitamin A. It helps moisturize and soften skin when used in body products. The soft, flexible texture it provides makes it an excellent addition to bath and body candle wax blends.

Soy Wax

Soy wax is made from hydrogenated soybean oil. It is a natural, biodegradable wax produced from a renewable resource. Soy wax has a creamier color and texture than paraffin wax. It has a medium melting point and makes glossy candles with a smooth surface. Soy wax candles burn slower and cooler than paraffin, and the wax pools evenly as it liquefies. Soy wax also holds scent well. The natural properties make soy wax a good choice for container candles.

Palm Wax

Palm wax is made from palm oil, which comes from the fruit of palm trees. It is a natural and sustainable wax choice. Palm trees produce palm fruit that can be processed into palm oil, providing an renewable and ecologically friendly raw material for candle making.

Palm wax has a soft, smooth texture that creates nicely rounded candles. It is softer than paraffin and soy wax, giving it a distinctive velvety feel. The pliability of palm wax enables creative techniques like hand rolling candles into various shapes. The softness also allows candles made from palm wax to adhere well to glass containers.

Coconut Wax

Coconut wax is made from hydrogenated coconut oil. It is an all-natural, non-toxic candle wax derived from renewable resources. Compared to paraffin wax which is a byproduct of petroleum refining, coconut wax is more environmentally-friendly. It has a high melting point and produces candles with excellent scent throw and clean burn.

The texture of coconut wax is hard and brittle, making it ideal for containers and molds. It can also hold more fragrance oil than other natural waxes. The natural hardness provides good hold for embellishments like flowers and glitter. It cools and sets up quickly which helps retain a candle’s shape.

A downside of coconut wax is that it shrinks more than other waxes as it cools. Care must be taken to properly adhere the wax to the container walls to prevent pull away. It also does not blend well with other waxes. Typically, coconut wax is used on its own or just blended with a small amount of beeswax or paraffin.

Gel Wax

Gel wax is another popular choice for candle making. It is a mineral oil based wax that has a clear, transparent appearance. Unlike other waxes, gel wax has a hard texture that holds its shape well. When melted and poured into containers, it creates smooth candles with a glossy finish. Gel wax allows vivid colors and decorative objects to be seen through the wax. It can also hold heavy fragrance oils withoutlosing its hardness or clarity. The biggest advantage of gel wax is that it does not shrink, crack or release easily from container walls when cooling. This makes it perfect for securing embeds and creating detailed designs on the candle surface. Gel wax burns slowly and provides a very even wax pool when lit. The hard finish results in candles that retain their shape nicely. While it has great visual appeal, the drawback is that gel wax is more expensive than common waxes. But for designers interested in showcasing colors and designs, it can create stunning decorative candles.

Additives

Candlemakers can add various additives to candle wax to enhance the look, smell, and burn quality of the finished candle. Some common additives include:

Dyes – These are used to color the wax and give candles a vibrant, consistent hue. Popular dyes used in candlemaking are liquid dyes, dye blocks, and dye chips. The dye must be formulated for high temperatures so it retains its color when the wax is melted.

Scents – Fragrance oils and essential oils are added to give candles pleasing aromas. Fragrance oils are synthetic scents created to mimic natural smells. Essential oils are extracted directly from plants and can provide therapeutic benefits. The oils are blended into the melted wax but the scent usually lasts longer in soy and vegetable waxes compared to paraffin.

Essential oils – Some makers add essential oils like lavender, eucalyptus, chamomile, etc. to provide aroma-therapeutic benefits. The oils can relax, rejuvenate, or energize. But they may influence how the candle burns so testing is required.

These additives must be formulated for candles specifically. The right quantities must be used to avoid issues like poor scent throw, smoking, tunneling, and more. Testing the blends allows candlemakers to achieve the perfect look, smell, and burn.

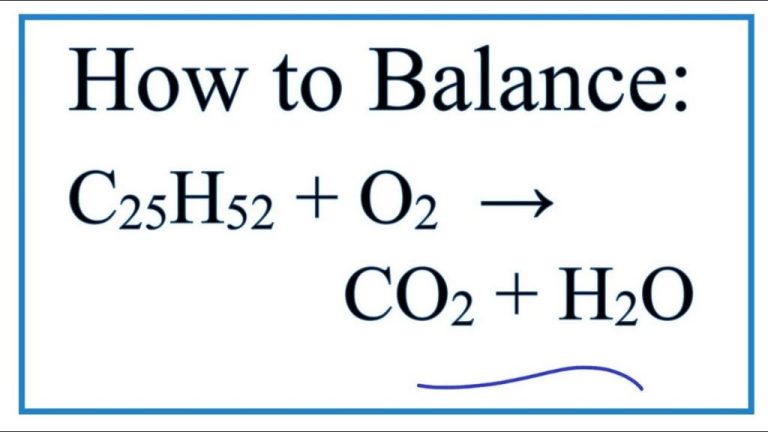

Making Candles

The process of making candles involves selecting the right wax for the job and properly preparing the wax to ensure high quality candles. Choosing a wax with the appropriate melting point is crucial. If the melting point is too high, the wax will be difficult to work with. If it’s too low, the finished candle may not hold its shape in hot environments. Most candle waxes melt between 120-160°F.

Candle wicks are another key component. Wicks come in different materials, thicknesses and shapes. Cotton and paper fiber wicks are common. The wick must be wide enough to allow the fuel (wax) to travel up while burning, but narrow enough to hold a flame without generating excess smoke. Wicks are usually straight or folded/braided to allow more wax flow.

After pouring wax into the candle vessel and inserting wicks, the candles should cure for 24-48 hours. This allows the wax to completely solidify and stabilize. During curing, crystals form in the wax which affects the melt pool, burn rate and fragrance retention. Proper curing helps ensure the wax adheres tightly to the wick and container. The finished candles will have a better surface appearance and burn more evenly.

Conclusion

The most common types of wax used to make bath and body candles include paraffin, beeswax, soy wax, palm wax, coconut wax, and gel wax. Each wax type has its own unique properties that impact burn time, fragrance throw, texture, color, and more.

When choosing a candle wax, key factors to consider are the melting point, scent throw, environmental impact, and personal preferences regarding texture and appearance. Paraffin is inexpensive but not eco-friendly. Beeswax and soy wax are natural options. Gel wax allows vibrant colors and embeds. Ultimately the wax type determines the look, feel, and performance of the finished candle.

By understanding the characteristics of the various bath and body candle waxes available today, candle makers can select the appropriate wax to match their creative vision, performance needs, and sustainability goals. The possibilities are endless when working with quality candle wax.