How Do You Make A Strong Smelling Scented Candle?

Scented candles have been used for thousands of years to bring pleasant aromas and ambiance into homes. While unscented candles were initially created for practical lighting purposes, the addition of fragrance oils allowed candles to serve decorative and therapeutic purposes as well. Today, millions of people enjoy making scented candles as an engaging hobby, creative outlet, and business opportunity.

This guide will provide a comprehensive overview of the scented candle making process, from choosing the perfect fragrance oils and wax to troubleshooting common issues. We’ll cover key steps like selecting the right wick, recommended fragrance loads, pouring temperatures, vessel options, curing methods, and safety tips. Our goal is to equip the reader with everything they need to start crafting stunning scented candles safely and successfully.

Choosing Fragrance Oils

When making scented candles, choosing the right fragrance oil is crucial for achieving a strong aroma. Some of the most popular fragrances for candles include floral scents like jasmine and lavender, fruity scents like apple and mango, and earthy aromas like sandalwood and cedarwood (Aromahpure, 2023).

There are a few key factors to consider when selecting fragrance oils:

- Strength – Some fragrance oils have a much stronger aroma than others when used in candles. Look for oils labeled as having high intensity or strength.

- Fragrance notes – Fragrances are composed of top, middle and base notes that evaporate at different temperatures. Choose oils with strong middle and base notes that will smell stronger when burned.

- Mixing – You can blend multiple fragrance oils to create unique scents. Make sure any mixed oils are compatible.

Testing different fragrance oil options and combinations is the best way to find the perfect candle scents. Focus on oils known for their strong aromas at typical candle temperatures (Lonestar Candle Supply, 2023).

Wax Type

The wax you choose for your candle is one of the most important factors that will determine the quality and performance of your finished candle. Here are some of the most common waxes used in candle making and their pros and cons:

Paraffin Wax

Paraffin wax is derived from petroleum. It’s the most widely used candle wax due to its low cost and excellent scent throw. Paraffin wax is easy to work with since it has a low melting point and makes glossy, hard candles. However, paraffin wax produces more soot than other waxes when burned and is not environmentally friendly since it is a byproduct of oil refining.

Soy Wax

Soy wax is made from hydrogenated soybean oil. It’s a renewable and sustainable wax made from plants. Soy wax burns cleaner than paraffin with less soot. It also holds fragrances very well. However, soy wax is more expensive than paraffin and can be tricky to work with since it shrinks and contracts more as it cools.

Beeswax

Beeswax is a natural wax made by honey bees. It has a pleasant natural honey aroma when burned. Beeswax is biodegradable, non-toxic and burns very cleanly. However, beeswax is expensive and has a low melting point, making it difficult to work with. It also does not hold scents as well as paraffin or soy wax.

Coconut Wax

Coconut wax comes from the oil of coconut palms. It is a sustainable natural wax. Coconut wax holds fragrances extremely well and burns cool and slow. However, coconut wax can be prone to frosting and sweating in some environments and is prone to cracking and mold growth if not mixed with other waxes.

Wick Selection

Choosing the right wick is crucial for achieving a strong scent throw in candles. The wick size should match the wax type and desired flame size. Larger wick diameters allow more fragrance to be released as the wax pool melts.[1] For soy wax, eco-friendly wood or paper core wicks work well since they curl and release more fragrance. [2] With paraffin wax, zinc or tin core wicks stand upright and provide excellent scent diffusion. Testing different wick sizes to find the optimal flame for your wax and fragrance is recommended.

Recommended Fragrance Load

The fragrance oil to wax ratio is an important factor in creating strongly scented candles. As a general guideline, most candle makers recommend using 5-15% fragrance oil by weight. This means if you are making a candle with 10 ounces of wax, you would use 0.5 – 1.5 ounces of fragrance oil.

However, the optimal amount can vary based on the wax type, fragrance oil, vessel size, and personal preference. It’s recommended to test different fragrance loads, starting on the low end at 5% and slowly increasing to find the sweet spot. For very large candles, a load up to 15% may be needed to achieve sufficient scent throw. But take care not to go over 15% as this can cause issues like wet spots, frosting, and poor burn performance.

One method is to make several sample candles with the same wax and wick, but test progressively higher fragrance loads like 6%, 8%, 10%, etc. Evaluate how well each sample’s scent throws when burning. The goal is to find the lowest percentage that still provides a nicely scented experience, without wasting excess fragrance oil. This testing can help zero in on the ideal load for that particular wax-fragrance blend.

Some fragrances also naturally have a stronger scent than others, so higher loads may not be needed. It’s best to reference manufacturer recommendations, then test batches yourself. Finding the optimal fragrance load for each candle recipe is important to create strong aroma without compromising quality.

Pouring Temperature

The pouring temperature for scented candle wax is crucial for achieving a good scent throw. According to How to Heat & Pour Wax for Candle Making, the ideal pouring temperature is between 125°F – 145°F. Pouring the wax too hot, above 150°F, can cause the fragrance oil to burn off or evaporate during the pouring and cooling process. This will result in a weaker scent in the final candle. Pouring below 120°F may lead to a poor pour and wet spots on the candle surface as the wax cools and solidifies too quickly.

Maintaining the wax within the optimal pouring temperature window allows enough time for the fragrance oil to properly bind with the wax before it fully hardens. This helps maximize scent throw and provide an even, strong fragrance when the candle is burned. Testing different pouring temperatures within the recommended range may be necessary depending on factors like the specific type of wax, fragrance load, and ambient climate conditions.

Curing Process

Proper curing time is essential for maximizing scent throw in candles. During the curing process, the fragrance oil permeates the wax which allows the scent to be released when the candle is burned. According to CandleScience, “The minimum cure time is 3 days, while 1-2 weeks is the preferred curing time, especially for natural waxes such as soy and coconut.”

Here are some tips to get the most out of the curing process:

- Allow candles to cure in a dry, well-ventilated area away from direct light and heat. Temperature and humidity fluctuations can affect cure time.

- Cover the candle with a lid or foil during curing to lock in fragrance. According to Jessica Welling Interiors, “The fragrance oil binds to the wax during this process, so cure time is essential to reach maximum scent throw.”

- Longer cure times are better, so have patience! Try to cure candles for at least 1-2 weeks before burning.

- Don’t burn candles immediately after pouring and cooling. Burning too soon can negatively impact scent throw.

- Write the pour date on the bottom of the candle to keep track of cure time.

Taking the proper time to cure candles allows the fragrance to fully mature within the wax, resulting in a stronger aromatherapy experience when burned.

Vessel Choice

The type of vessel you choose for your candle is an important factor that impacts fragrance strength and throw. Here are some key considerations:

Jar Size – Larger jars allow more fragrance oil to be added, increasing scent throw. However, the larger the candle, the larger the wax pool when burning. This can actually negatively impact scent throw if the wax pool is too large. Ideal jar sizes for strong scented candles are around 8-12oz.

Lid – Candles with lids helps concentrate the fragrance when not being burned. Metal lids in particular help hold in fragrance when the candle is not lit.

Material – Glass and metal vessels do not absorb fragrance like porous materials such as concrete or wood. This allows more of the scent to be released into the air.

Test different jar styles to find the perfect vessel for maximizing hot and cold scent throw. Avoid containers that are too large or made from porous, fragrance-absorbing materials. Focus on glass jars with tight-fitting lids around the 8-12oz range for strongest fragrance.

Safety Tips

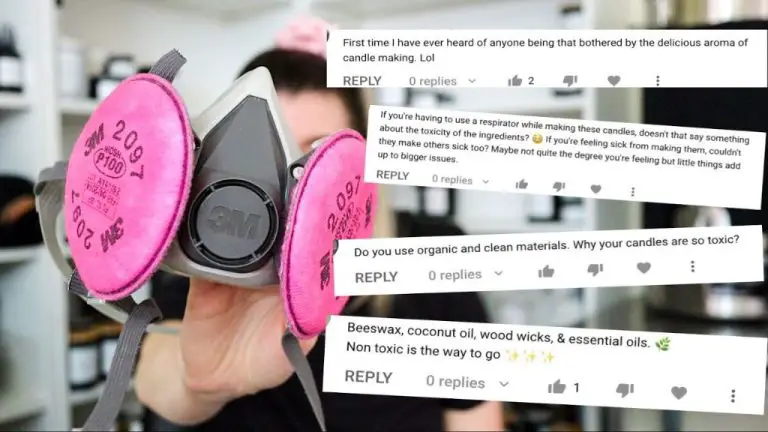

Candle making can be an enjoyable hobby, but there are some key safety precautions to follow. Proper ventilation is critical – make sure to work in a well-ventilated area since melting wax produces fumes. Open windows, use fans, or consider working outside. Wear safety equipment like heat-resistant gloves and long sleeves when pouring hot wax. Follow manufacturer guidelines for any equipment used. Store finished candles away from heat sources or flammables. Let candles cure 2-4 weeks before lighting so they burn properly. Never leave burning candles unattended. Keep wicks trimmed to 1⁄4” length to prevent smoking (https://northwoodcandlesupply.com/blogs/news/5-candle-making-safety-tips-everyone-should-follow). Position candles on stable, heat-safe surfaces. Extinguish candles once they reach 1⁄2” wax depth. Take extra precautions with children and pets around hot wax or lit candles.

Troubleshooting

Here are some common issues that can lead to weak scent in candles and how to fix or prevent them:

Not adding enough fragrance oil – Use the recommended fragrance load percentage for the wax type according to manufacturer guidelines, usually 6-10% for soy wax (https://villagecraftandcandle.com/blogs/news/top-10-candle-making-problems-and-how-to-solve-them). Adding more fragrance than recommended can actually make the scent weaker.

Pouring wax too hot – Pour soy wax around 185°F to properly bind fragrance oil (https://www.candlescience.com/wax/soy-wax-trouble-shooting-guide/). Hotter wax can burn off scent.

Improper wick – Make sure the wick size suits the candle diameter and wax type. A wick that is too small can lead to poor scent throw.

Insufficient curing – Allow candles to cure for 24-48 hours before lighting to allow the fragrance oil to fully bind to the wax.

Old fragrance oil – Always use fresh fragrance and store tightly sealed. Fragrance oils can lose potency over time.

Temperature shock – Avoid exposing candles to extreme temperature swings. This can cause the wax and fragrance to separate.