How Do You Light An Oil Wick Candle?

Oil wick candles have a long history dating back thousands of years. The earliest forms of wicked candles using oil fuels emerged around 3000 BC in ancient Egypt and the Middle East, where oils like olive oil were burned with fiber wicks to produce light. These primitive candles were created by soaking the fiber wicks in the oil fuel.[1]

By about 1000 BC, Romans began mass producing dipped candles by repeatedly soaking wicks in melted tallow (animal fat). While olive oil lamps were more common, candles became popular in ancient Rome as an inexpensive light source.[2]

Oil wick candles continue to burn bright today as an attractive flameless light source. They work by using capillary action to draw oil fuel up through the wick, which then burns and melts at the wick tip to produce a clean flame.

Safety First

When using open flames like oil candles, safety should always be your top priority. Here are some key safety tips and precautions to keep in mind:

According to Candle and Oil Lamp Safety – Be Ready Utah[1], you should always keep a fire extinguisher or bucket of water nearby when burning an oil candle. Never leave a burning candle unattended.

Most importantly, lamp oil is not very flammable and will not burn without a wick[2]. If a candle is knocked over, the fuel will not ignite. However, the wick can still be hot and cause burns, so use caution.

According to Indoor Oil Lamp and Candle Safety Tips[3], always keep lit oil lamps in a well-ventilated area to prevent build up of fumes. Adjust the wick so only about 1/4″ is showing to prevent overly large flames.

In summary, practice common sense fire safety, never leave a burning candle unattended, and ensure proper ventilation when using oil candles.

Materials Needed

Making an oil wick candle requires just a few basic supplies that can easily be found online or at local craft stores. The main materials you’ll need include:

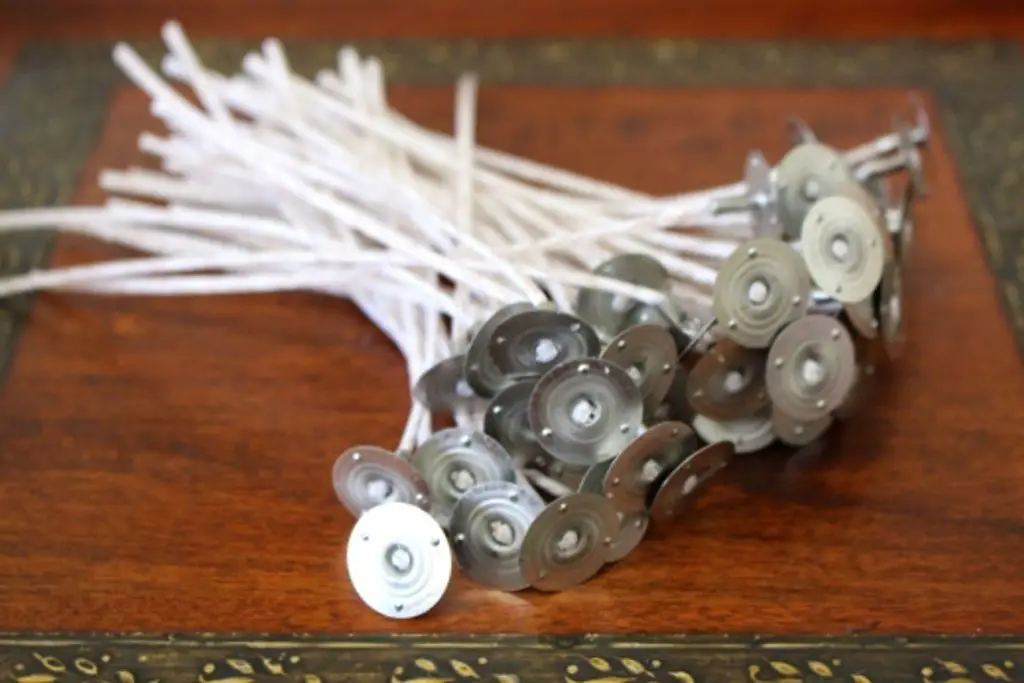

- Wick – Oil candle wicks are typically made of cotton or fiberglass. Choose an appropriate wick size and type for your container. Good options include pre-tabbed fiberglass wicks.

- Wax – Use a wax with a low melting point, like paraffin or soy wax. Paraffin wax melts at approximately 115-150°F. Measure out at least 1 lb of wax per 16 oz of oil.

- Fragrance oil – Essential oils or candle fragrances specially formulated for wax melting points. Use 1-2 ounces of fragrance per 1 lb of wax.

- Container – Glass containers like bottles, jars, or vases work well. Make sure it’s heat safe up to 180°F.

- Candle making supplies – These include double boiler, thermometer, pouring pot, dyes, etc.

Once you have your basic materials, you’re ready to start preparing your oil wick candle!

Prepping the Wick

The wick is a crucial component of an oil wick candle, as it draws up the fuel to the flame. Properly preparing the wick helps ensure an even, steady burn. Start by trimming the wick to fit the container, leaving about 1⁄2 inch extra. According to eHow, priming the wick before use helps it burn more efficiently. To prime, soak the wick in hot melted wax until saturated. You’ll see bubbles as trapped air escapes. Allow it to dry completely. Next, center the wick in the container by attaching it to a pen or skewer placed across the top. Adjust the wick so it hangs straight down the middle without touching sides.

Source: https://www.ehow.com/info_12108062_homemade-oil-lamp-wicks.html

Melting the Wax

Before pouring the wax into containers, it must be properly melted. According to Nikkura, beeswax has a melting point between 155-160°F. It’s important not to overheat the wax, as this can cause discoloration and affect fragrance retention.

The double boiler method is recommended for melting wax. Fill a pot halfway with water and bring it to a simmer. Place your wax in a heat safe container, then put the container in the pot of simmering water. This allows the wax to melt gradually and evenly without scorching. Stir the wax occasionally as it melts to keep the temperature consistent. Use a thermometer to monitor the temperature and keep it within the recommended melting range for your wax type. Once fully melted, remove the wax container from the double boiler and allow it to cool slightly before adding fragrance.

Adding Fragrance

Choosing the right fragrance oil is crucial for creating a great smelling candle. When shopping for fragrance oils, look for candle-safe oils specifically formulated for soy, paraffin, or beeswax candles. Some popular options include floral, fruity, woodsy, and fresh scents.

The standard fragrance load for container candles is 6-8% of the wax weight. For example, if you are making a 6 oz candle, and using 10 oz of wax, you would need 0.6-0.8 oz of fragrance oil. Gel candles usually use a lower fragrance load around 4-5%. It’s important not to use too much fragrance oil as it can cause issues like fragrance throw, scent fading, or smoking.

Thoroughly mix the fragrance into the melted wax before pouring into containers. Stir gently to fully incorporate without creating air bubbles. You may need to experiment with different fragrance loads to find the right balance and intensity of scent for your preferences.

Prepping the Container

Before pouring wax into the container, it’s important to properly prepare the vessel. Start by cleaning the container thoroughly to remove any dust, oils or debris. You can wipe the interior with a paper towel and a bit of rubbing alcohol.1

Next, make sure your container has a hole in the bottom center to thread the wick through. The wick hole should be just big enough for the wick to fit snugly. If there is no hole, carefully drill one with a bit slightly larger than your wick.

Finally, preheat the container before pouring in wax. This prevents the wax from cooling and hardening too quickly. Place empty containers in a 150-170°F oven for 10-15 minutes. The “keep warm” setting also works well.2 Preheating helps the wax adhere to the container better for a smooth finish.

Pouring the Wax

Once your wax is melted completely and you have added any desired fragrance or dye, it’s time to pour the wax into the candle container. Be sure to pour the wax when it has cooled to the proper temperature. For soy wax, the optimal pouring temperature is between 135-140°F (according to https://lonestarcandlesupply.com/heating-and-pouring-waxes/). If the wax is too hot, it can scorch or discolor. If it’s too cold, you may end up with frosting or poor adhesion.

As you pour the wax, be very careful not to disturb or move the wick. The wick needs to remain centered and straight for proper burning. Gently pour the wax down the side of the container in a thin stream. This will help prevent air bubbles from forming. Allow the candle to cool completely undisturbed. Cooling can take 6-12 hours. Resist the urge to move or mess with the candle during this time. Once fully cooled and set, you can trim the wick if needed.

Troubleshooting

Even when following all the proper steps, you may run into some issues with your oil wick candle. Here are some common problems and how to fix them:

- Sinkholes – This happens when the wick melts the wax too quickly, creating a hole. Switch to a smaller wick or try a different wick type. According to CandleScience, “If the wick is too large, the wick will consume too much fuel too quickly, causing it to generate too much heat and melt right down the middle of your candle.”[1]

- Wick issues – If the flame is too small or large, the wick is likely the culprit. Trim the wick or switch to a thicker or thinner wick until the flame is a proper size.

- Frosting – This white, powdery film can happen if the wax gets too cold. Gently warm the candle to re-melt the outer layer of wax.

- Wax separation – If the fragrance oil separates from the wax, try mixing again at a lower temperature or use less fragrance oil.

Be patient and tweak your procedure until you get the results you want. Making candles is an art that takes some practice!

Curing and Enjoying

After pouring your candle, it’s important to let it cure before lighting. Curing allows the wax to harden completely and anchors the fragrance, resulting in an even burn and stronger scent throw. The curing process can take 1-2 weeks, though soy wax candles should be cured for 24-48 hours. Be sure to cover the candle with a lid or protective wrap during curing to prevent any dust settling on the surface. Leaving the lids off will cure the outside edges first, which results in tunneling or an uneven burn. Storing in a room temperature environment is ideal to avoid any cracking. Once fully cured, you can trim the wick to 1⁄4 inch before lighting.

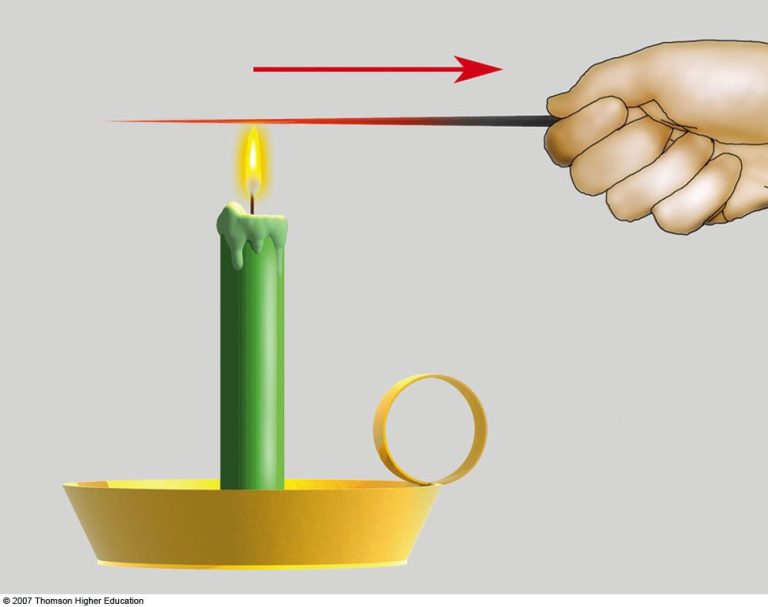

When ready to light, take care not to burn the candle for more than 2-4 hours at a time. Longer burn times can cause soot buildup and reduce how long the candle lasts. Make sure to keep the wax pool free of debris and trimmed wicks for the best performance. With proper curing and lighting habits, an oil wick candle can provide dozens of hours of aromatic ambiance and soothing light.