How Can I Dye Fabric Brown?

Dyeing fabric brown is a great way to refresh old linens or clothing, match existing decor, or give fabric a new earthy look. With the rise in brown’s popularity as an interior design trend for 2024 according to Fibreguard, dyeing fabric this versatile neutral offers many decorating possibilities. Brown also remains on-trend in fashion, with its earthy and natural aesthetic as noted by Vox. By dyeing fabric brown yourself, you can update pieces affordably and customize shades to perfectly match your style and decor.

In this guide, we’ll cover techniques for dyeing fabric brown using both natural and commercial dyes. We’ll provide tips on preparing fabric, achieving different shades of brown, and setting the dye. You’ll learn how to troubleshoot any dyeing issues and properly care for your finished brown fabric. With the right approach, dyeing fabric brown can update old pieces with a fresh on-trend look.

Natural Dyeing Methods

Natural dyes are a great way to achieve beautiful brown shades on fabric without using harsh chemicals. Many common household items like tea, coffee, spices, nuts, and barks contain tannins and other brown pigments that can be used to dye fabric. Here are some options for achieving natural brown dyes:

Tea is one of the easiest natural dyes for getting light brown hues. Both black and green tea can be brewed strong and used to dye fabric (Source 1). The longer the fabric soaks in the tea bath, the darker the brown color will become.

Coffee is another readily available dye for medium to dark brown shades. Leftover coffee grounds can be saved and simmered with fabric to transfer the deep brown color (Source 2). Adding a rusty iron object to the dye bath will make the brown even darker.

Onion skins, walnut hulls, acorn shells and cinnamon sticks are some natural materials that produce warm brown and tan dyes thanks to their tannin content. Simmering them in water creates a dye bath that can be used to dye fabric various shades of brown.

Darker brown hues can be achieved using the bark and hulls of trees like oak, pine and sassafras. Chipping the bark and boiling it releases the deep brown tannins that bind to fabric for long-lasting natural brown dyes.

Commercial Dyes

There are a few options when it comes to using pre-made brown fabric dyes. Some popular brands include Rit, iDye, Dylon, and Jacquard (ProChemicalandDye, n.d.).

Some pros of using commercial dyes include:

- Convenience – The dye already comes pre-mixed and ready to use.

- Consistent results – Commercial dyes are designed to achieve reliable, even coloring.

- Variety – Many brands offer different shades of brown to choose from.

- Beginner friendly – These dyes are easy to use even for dyeing novices.

Some potential downsides include:

- Less customization – You’re limited to the pre-mixed shades offered.

- Harsher on fabrics – Some commercial dyes contain more synthetic chemicals.

- Less environmentally friendly – Many commercial dyes are petroleum-based.

- Can fade faster – Natural dyes may produce longer-lasting browns.

Overall, commercial dyes provide a simple and reliable way to dye fabric brown. But natural dyes may offer more customization and environmental benefits for those willing to put in the effort (ProChemicalandDye, n.d.).

Dyeing Techniques

There are several techniques that can be used to dye fabric brown.

Immersion Dyeing

Immersion dyeing involves submerging the entire fabric into a dye bath. This allows the dye to fully penetrate the fabric and produce an even, all-over color. To dye fabric brown using the immersion technique:[1]

- Fill a pot with enough water to fully submerge the fabric. Add brown dye to the water following package instructions.

- Heat the dye bath to a simmer. Keep the temperature consistent when dyeing.

- Add pre-soaked fabric to the pot and stir continuously for 30-60 minutes. Longer dyeing times produce darker shades.

- Remove the fabric and rinse thoroughly in cool water until the water runs clear.

Tie Dye

Tie dyeing involves tying, twisting, scrunching or folding the fabric before dyeing to create patterns. For tie dyeing with brown:[2]

- Prepare brown dye according to package instructions in a bucket or basin.

- Twist, crumple or fold the pre-soaked fabric and secure it with rubber bands or string.

- Submerge the tied fabric in the dye bath for 15-60 minutes.

- Remove the ties to reveal the pattern. Rinse and wash the fabric.

Ombre Dyeing

Ombre dyeing produces a gradual shift in color, with light shades at one end and darker shades at the other. To ombre dye with brown:[1]

- Soak fabric in a soda ash solution to help the dye bond.

- Fold the fabric in half lengthwise and secure one half with clamps or clips.

- Submerge the untied half in brown dye for 15 minutes. Then submerge the tied half.

- The tied section will dye darker. Rinse thoroughly after dyeing.

Experiment with different techniques to achieve your ideal brown shade.

Preparing the Fabric

Properly preparing your fabric before dyeing is an essential step for achieving an even and colorfast dye. Here are some key steps for pre-dye fabric preparation:

Washing – Make sure to wash your fabric prior to dyeing using a gentle detergent. This will remove any dirt, oil or sizing that could prevent the dye from absorbing evenly into the fibers. For best results, wash fabric in hot water. Source

Removing sizing – If you are dyeing a new fabric like cotton or linen, it likely has sizing applied to give it stiffness. This sizing needs to be removed prior to dyeing or it will prevent dye absorption. Soak the fabric in warm water for 30 minutes, then rinse thoroughly. Source

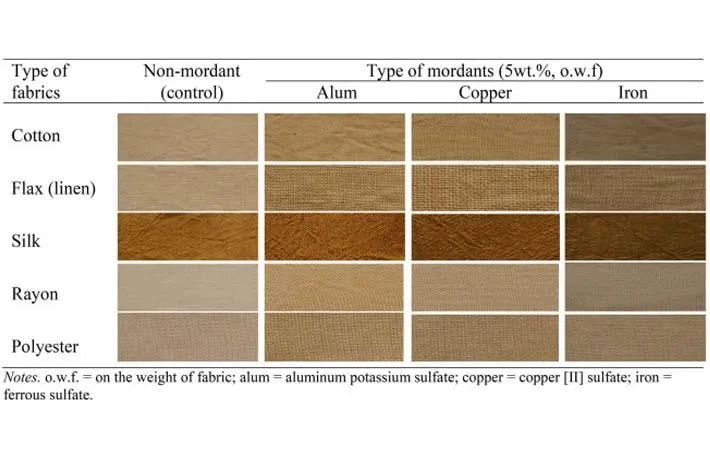

Mordanting – Most natural dyes require a mordant to help the dye bond permanently with the fabric fibers. Mordants are usually metallic salts that act as a “bonding agent”. Common mordants used are alum, iron, and tannin. Follow specific mordanting steps based on the dye recipe. Proper mordanting leads to colorfast results.

Dyeing Process

The dyeing process will vary slightly depending on whether you are using natural dyes or commercial dyes. Here are the basic steps for dyeing fabric brown:

First, prepare your dye bath. For natural dyes, boil the flowers, leaves, nuts, etc. in water to extract the dye. For commercial dyes, mix the dye powder with hot water according to the package directions. You may need to add a fixative like vinegar or salt.

Wet the fabric by soaking it in plain water first. This allows it to absorb the dye better. For protein-based fibers like wool or silk, a mordant like alum may be needed.

Add the wet fabric to the dye bath. For even coloring, stir and move the fabric frequently. Keep heating the bath, but do not boil once the fabric is added.

Allow the fabric to soak until the desired shade of brown is reached. This may take 30 minutes to an hour or more, depending on the dye source. Check the fabric regularly.

Remove the fabric and rinse thoroughly in cool water to remove excess dye. Repeat rinses until the water runs clear.

If using natural dyes, an optional step is to soak the dyed fabric in a fixative solution such as vinegar or iron oxide to better set the color.

Wash the dyed fabric separately before first use. Brown dyes may bleed or crock if not properly set, especially on natural fibers.

For more details and tips, refer to this guide on using natural dyes or these instructions for dyeing with commercial dyes.

Achieving Different Brown Shades

There are a few techniques you can use to achieve lighter, darker, or more reddish brown shades when dyeing fabric:

Light Brown

To achieve a lighter brown shade, use less dye powder or leaves. For natural dyes, you can create a lighter dye bath by using fewer dye sources. With commercial dyes, carefully follow the package instructions but use less dye powder. You can also soak the fabric for less time in the dye bath.

Dark Brown

For a deep, dark brown, use more dye powder or plant material to create a highly concentrated dye bath. With natural dyes, use more leaves, bark, roots, etc. For commercial dyes, use the maximum recommended amount of dye powder. Soak the fabric for a longer amount of time as well.

Reddish Brown

To give your brown a warmer, redder tone, try adding a small amount of red dye. With natural dyes, you can add things like madder root, avocado skins/pits, or red onion skins. For commercial dyes, add a touch of red dye to the brown dye bath. Start with just a pinch and increase as desired.

Setting the Dye

Once you have dyed your fabric the desired shade of brown, it is important to properly set the dye so the color remains vibrant and does not fade, bleed or wash out. There are two main techniques for setting fabric dye – heat setting and chemical setting.

Heat Setting

Heat setting involves baking the dyed fabric at high temperatures to permanently bond the dye to the fibers. To heat set fabric dye, prewash the dyed fabric in hot water to remove any excess dye. Then place the wet fabric in a baking pan or oven-safe dish and bake at 300-350°F for 30-60 minutes. The high heat helps drive the dye into the fabric fibers and makes the color fast. When heat setting, check frequently to ensure the fabric does not burn.

Chemical Setting

Chemical setting uses a fixing agent or mordant to bind the dye to the fabric. Common chemical fixatives include vinegar, salt, and soda ash. To chemically set fabric dye, soak the dyed item in a fixer solution for at least 30 minutes. Vinegar or salt can be used for protein-based fibers like wool or silk. Soda ash is ideal for plant-based fibers like cotton or linen. The chemical solution reacts with the dye and fibers to lock in the color. After soaking, rinse thoroughly in cool water to remove excess chemicals.

Both heat setting and chemical setting are effective ways to make dyes colorfast on fabric. Combining both methods provides extra dye protection for heavy use items like towels or tablecloths. Once set, the brown fabric dye should retain its rich color through many washings.

Caring for Dyed Fabric

Proper care is essential for preserving the color and integrity of your hand-dyed fabric. Most plant dyes are not as colorfast as synthetic dyes, so special precautions should be taken.

When washing dyed fabric, use a gentle, pH-neutral detergent like Synthrapol and wash in cool or lukewarm water. Agitation should be minimal – hand washing or a gentle cycle in the washing machine is best. Avoid using chlorine bleach or fabric softener, as these can negatively impact dyes.

The lightfastness of natural dyes can vary. Indigo, madder and black walnut tend to be very colorfast. Dyes like turmeric and avocado will fade more quickly. Store dyed textiles out of direct sunlight to help prolong their color. Consider lining or underlining clothing made with fugitive dyes if frequent washing is needed.

With proper care, most naturally dyed fabrics will remain beautifully vibrant for many years. Handle your hand-dyed textiles gently, avoid direct sun exposure, and wash only when necessary using a dye-safe detergent. Follow the washing guidelines above and your fibers will maintain their natural hues.

Troubleshooting

Dyeing your own fabric can be rewarding, but sometimes things don’t go as planned. Here are some common issues when dyeing fabric brown and how to fix them:

Uneven Dyeing

If you end up with splotches of uneven color, it could be because the dye wasn’t distributed evenly during the dyeing process. Make sure to stir the dye bath frequently and massage the dye thoroughly into the fabric. Using a dye fixative like vinegar or salt helps the dye bind evenly. If the dye job is still splotchy, you can try overdyeing to even out the color.

Fading

There are a few reasons why your brown dye may fade over time. Using too little dye, insufficient dye time, or inadequate rinsing can all lead to fading. Make sure to use enough dye for the amount of fabric, and allow it to soak sufficiently. Rinse the fabric thoroughly in cool water until the water runs clear. Using a dye fixative helps the color remain vibrant. Store dyed fabrics out of direct sunlight to minimize fading.

Color Wasn’t As Expected

Sometimes the final color doesn’t turn out how you envisioned. Factors like the dye type, fabric composition, and dyeing method all impact the final result. Synthetic dyes tend to create more vibrant and predictable colors than natural dyes. Make sure to choose a dye suitable for your fabric type. Adjust the dye quantity, dilution, and process to get the shade you want. Consulting online dyeing communities like Reddit can provide troubleshooting tips.