What Is A Wax Liner?

A wax liner is a removable cartridge made of wax that is used inside flasks, jars, bottles, and other containers. Wax liners create an airtight seal to preserve and protect the contents. The wax conforms to the shape of the container’s opening and neck.

Wax liners provide many benefits compared to other types of bottle seals. The wax barrier prevents oxidation, evaporation, and contamination. It can also extend the shelf life of contents. Wax liners are commonly used when canning foods, for cosmetics and toiletries, chemical storage, arts and crafts supplies, and more.

Wax liners are an economical and eco-friendly way to seal containers. The wax can be reused by melting and re-pouring it into containers. Wax liners are often preferred over plastic and foil seals because they contain no BPAs or other chemicals.

History of Wax Liners

Wax liners first started being used in the early 1900s as a protective coating for metal food cans. At the time, most food cans were made of steel and had no internal coating. This allowed the food to interact with the metal, leading to corrosion and food spoilage. The wax coating provided a barrier between the food and the metal, helping preserve the contents.

One of the first documented uses of wax liners was in 1904 by the American Can Company. They began coating the interior of canned pineapple containers with paraffin wax to prevent the fruit’s acidic juices from reacting with the metal. This helped extend the shelf life of canned pineapple.

By the 1920s, wax liners had become widely adopted by canners as a low-cost and effective way to protect all types of canned foods. Refined paraffin waxes and later microcrystalline waxes were found to be food-safe and provided excellent corrosion resistance. Wax liners continued to be the industry standard up until the 1960s and 70s.

Materials

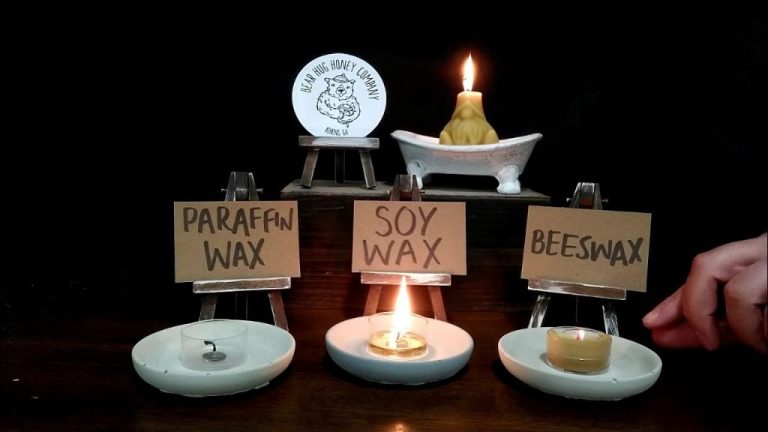

Wax liners are made from a variety of waxes, polymers, and other additives that provide specific properties and performance. The main ingredient is typically paraffin wax, which provides structure, flexibility, and water resistance. Other common waxes used include microcrystalline wax, which increases strength and durability, and polyethylene wax, which enhances flexibility and tear resistance.

In addition to waxes, wax liners often contain polymers like polyethylene and ethylene vinyl acetate (EVA) to make the liners more flexible and stretchy. Fillers like clay, calcium carbonate, and talc may be added to reduce cost and modify structure. Plasticizers are added to improve flexibility and processability. Antioxidants help guard against environmental degradation from factors like oxygen, ozone, and UV light. Dyes and pigments provide color.

The specific blend of waxes, polymers, and functional additives can be customized to produce wax liners with desired properties for different applications and performance requirements. Formulators balance ingredients to optimize stretch, strength, tear resistance, flexibility, and water barrier properties.

Manufacturing Process

Wax liners are primarily manufactured through a process called spin casting. This involves pouring molten wax into a spinning mold to evenly coat the interior surface. As the wax cools, it hardens into the shape of the mold.

The steps for spin casting wax liners are:

- Heat wax to 190-200°F to melt it into a liquid state.

- Pour the molten wax into a spinning mold mounted on a spin casting machine.

- Spin the mold at high speeds to evenly distribute the wax using centrifugal force.

- Continue spinning until the wax has cooled and hardened into a liner.

- Open the mold and remove the finished wax liner.

- Trim and smooth any excess wax material.

The spin casting process allows manufacturers to produce custom-shaped wax liner cavities to match the dimensions of a mold or die. It enables an even wax thickness throughout the liner. The high spin speeds help remove air bubbles for a smooth, consistent finish.

Some facilities also make wax liners using a process called injection wax molding. This forces molten wax into a mold under high pressure rather than relying on centrifugal force. However, spin casting remains the predominant method for manufacturing wax liners.

Uses

Wax liners have a variety of uses across several industries. Here are some of the main applications for wax liners:

Food and Beverage: Wax liners provide a protective barrier between food and beverage products and the containers they are stored and shipped in. This prevents contamination and helps maintain freshness. They are commonly used to line the inside of cans, bottles, jars, boxes and other packaging.

Pharmaceuticals: In the pharmaceutical industry, wax liners ensure tablets, capsules and medications do not stick to bottling and packaging equipment during production. This allows for efficient, high-speed manufacturing.

Chemicals and Industrial: Chemical tanks, drums and containers are often lined with wax to prevent corrosion and interaction between the chemicals and the metal tanks. This protects the structural integrity of the containers during transport and storage.

Cosmetics: Wax liners provide an impermeable barrier between cosmetics like lipstick, creams and lotions and their plastic or metal packaging. This prevents the products from drying out.

Overall, wax liners play a critical role across industries in protecting the quality and integrity of many products during manufacturing, shipping and use by consumers. The barrier properties of wax make it an indispensable material for lining packaging and containers.

Benefits

Wax liners offer a number of key advantages that make them a popular choice for many applications:

Corrosion Resistance – The wax coating provides excellent protection against corrosion for metal containers and equipment. This allows longer storage times and prevents deterioration.

Lubrication – The wax layer helps contents slide out more easily from containers. This makes wax liners useful for products like lip balm, creams, adhesives, etc.

Moisture Barrier – Wax liners prevent moisture loss and protect contents from drying out. This helps maintain freshness and extends shelf life.

Odor and Taint Prevention – The wax barrier prevents odors and tastes from the container transferring to the contents. This is important for food, pharmaceuticals and chemicals.

Heat Sealability – Wax liners can be induction heated and melted to bond with container flanges for an airtight seal. This allows secure and leak-proof packaging.

Economical – Wax liners are inexpensive to produce compared to other liner options like plastic. The raw materials and manufacturing process are relatively low cost.

Sustainable – As a natural material, wax liners are biodegradable and eco-friendly. Reusable containers with wax liners have environmental benefits over single-use plastics.

Overall, wax liners provide corrosion resistance, lubrication, moisture barrier, odor prevention, sealability, affordability, and sustainability advantages that make them a versatile and popular liner choice for metal packaging across many industries.

Limitations

Wax liners have a few notable limitations and disadvantages compared to other types of pool liners:

-

Durability – Wax liners typically only last 1-2 seasons before needing to be reapplied. They wear away more quickly than vinyl, fiberglass, or tile liners.

-

Appearance – The wax can become streaky or develop an uneven appearance over time. This requires reapplying and smoothing out the wax coating.

-

Slipperiness – Wax liners tend to be more slippery than other liner materials. This could present a safety issue, especially for children or elderly pool users.

-

Staining – Wax liners are prone to staining from lotions, oils, and other contaminants. These stains can be difficult to remove.

-

Temperature Sensitivity – Wax liners may soften and lose integrity in very hot weather. The coating needs reapplied each season.

-

Sealing Issues – Cracks and imperfections in the underlying pool surface must be thoroughly sealed. Any pinholes can lead to wax liner leakage.

While wax liners provide a cost-effective short-term solution, their lack of durability and high maintenance make them less than ideal for most pool owners.

Alternatives

There are a few alternatives that can be used instead of a wax liner:

Plastic liners – These are probably the most common alternative to wax liners. Plastic liners are made from materials like polyethylene and polypropylene. They are durable and long-lasting. Plastic liners can withstand higher temperatures than wax liners. They are more resistant to impact and abrasion. Plastic liners are usually a bit thicker than wax liners. They provide excellent corrosion protection. However, plastic liners can be more expensive than wax liners.

Rubber liners – Rubber liners provide similar performance to plastic liners. Rubber has natural corrosion inhibition properties. Rubber liners are flexible and impact resistant. They can withstand high temperatures. Rubber liners are more expensive than wax or plastic liners. Rubber liners may also be more difficult to install in some applications.

Ceramic liners – Ceramic liners provide very good corrosion protection at high temperatures. They are much more rigid than wax, plastic or rubber liners. Ceramic liners have a smooth surface that prevents buildup or clogging. They are chemically inert. However, ceramic liners are brittle and can crack or chip. They also have a high upfront cost.

Coatings – Some pipelines rely on anti-corrosion coatings rather than liners. Fusion-bonded epoxy and coal tar epoxy are common coating materials. However, coatings may be less reliable than a full liner, and could scratch, chip or peel away.

Cost

Wax liners are relatively inexpensive compared to other types of trash can liners. The exact cost depends on the size and quantity purchased:

- Small wax bag liners (10-20 count) – $1-3

- Medium wax bag liners (10-20 count) – $2-5

- Large wax bag liners (10-20 count) – $3-7

- Extra large wax bag liners (10-20 count) – $5-10

Buying in bulk brings down the per-bag cost. A case of 200 small wax liners may cost $20-40. Wax liners are cheaper than plastic trash bags since they use less material. Standard plastic trash bags can cost $0.10-0.50 per bag depending on size and quality.

Overall, wax liners provide an inexpensive option for lining small trash bins. Their low cost makes them accessible to most households and businesses.

Summary

Wax liners are an essential technology used across many industries. As we learned, wax liners have been around for over a century, originally developed to protect steel cans. Over time, the materials and manufacturing methods have evolved, but wax liners continue to serve the key functions of preventing corrosion, contamination, and interaction between the container and contents.

The most common materials used today are paraffin wax, microcrystalline wax, polyethylene, and other polymers. Manufacturing techniques like hot dipping, spray coating, and laminating allow creating a thin, flexible layer of wax or polymer that sticks to the interior metal surfaces. This provides a reliable barrier for food cans, chemical drums, metal tubes, and more.

Key benefits of wax liners are their low cost, chemical resistance, thermal stability, and ease of application. Limitations mainly relate to temperature; wax liners can melt or soften in high heat. Overall, these liners offer an indispensable solution for safety, preservation, and transport across industries. With ongoing innovation in materials science, wax liners will continue evolving to meet the needs of the modern world.