How Does A Candle Steam Boat Work?

A candle steam boat is a miniature steam boat powered by the heat from a burning candle. These small steam boats were popular children’s toys from the late 19th century until the mid 20th century.

The basic concept behind a candle steam boat is to use the heat from a candle to boil water, which creates steam. The steam is then piped to a small piston engine that powers a paddle wheel propelling the boat forward.

While simple in design, candle steam boats provide an engaging demonstration of how steam power works. The candle heats water in a small boiler which produces steam. The high-pressure steam is then piped to miniature pistons that move back and forth to turn a driveshaft. The driveshaft connects to paddle wheels that propel the boat forward across water.

In this overview, we’ll take a closer look at how the various components of a candle steam boat work together to harness the power of steam on a small scale.

Candle as Heat Source

A candle uses a simple chemical reaction to produce heat energy that can be harnessed to power mechanical motion. Specifically, a candle contains wax (typically paraffin) surrounding a wick. When the wick is lit, the wax melts and is drawn up the wick via capillary action. The heat of the flame vaporizes the liquid wax which is then drawn into the flame where it reacts with oxygen to produce heat, water vapor, and carbon dioxide.

This exothermic combustion reaction sustains itself as long as there is wax to fuel it. The key difference from heat sources like wood or coal is that the fuel, wax, is already built into the candle. The wax both provides the fuel for combustion through the wick and acts as a convenient solid form factor for the fuel. With wood or coal, the fuel is separate. This integrated design allows candles to provide a compact, self-contained heat source.

Candles produce a relatively small, steady amount of heat over a sustained period, unlike the burst of heat from igniting a larger quantity of solid fuel at once as with wood or coal. This makes candles ideal for small scale or hobby steam power applications.

Boiler

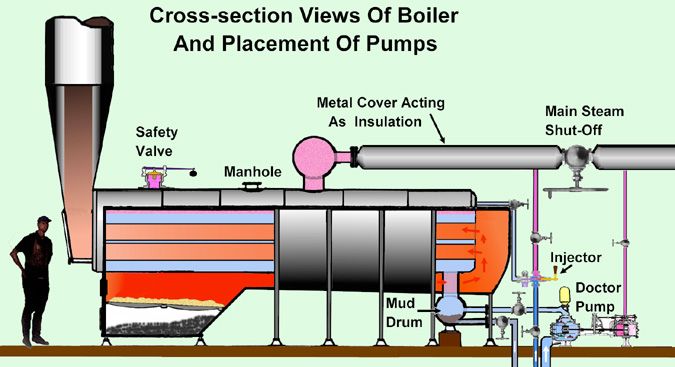

The boiler is a key component of a candle steam boat. It is a small chamber filled with water that sits above the candle flame. The heat from the candle vaporizes the water in the boiler, turning it into steam. This conversion of water to steam is an important process that enables the boat to move.

The boiler will have a small opening near the bottom where the candle can heat the water. It may also have a chimney at the top to let the steam escape. As the water gets hotter, it expands and turns into steam. The boiling point of water is 212°F (100°C), so the candle needs to heat up the water to this temperature for steam to form.

Some key design considerations for the boiler are that it should be well-sealed to build up steam pressure, made of heat resistant materials so it does not melt, and have sufficient volume to hold enough water to generate continuous steam. Insulating the boiler helps improve efficiency. Overall, an effective boiler is critical for converting the heat energy from the candle into usable steam power.

Piston and Cylinder

The piston and cylinder are responsible for converting the steam’s energy into mechanical motion. The cylinder is a hollow tube, usually made of brass or steel. Inside the cylinder is a piston that can slide up and down. The piston is a disc shaped piece, typically made from cast iron, that fits snugly inside the cylinder.

When the boiler heats water into steam, the high pressure steam is admitted into the cylinder via a valve. This high pressure steam pushes against the piston, forcing it to move down the length of the cylinder. As the piston moves downwards, it pushes on a connecting rod that turns the crankshaft. The crankshaft’s rotation provides the power to turn the paddle wheel and propel the boat.

Once the piston reaches the bottom of the cylinder, the pressure is released via an exhaust valve. With the pressure relieved, the piston is pushed back to the top of the cylinder either by momentum or a spring. At this point, high pressure steam is admitted again above the piston, pushing it downwards and repeating the power cycle. This reciprocating motion of the piston sliding up and down inside the confines of the cylinder is able to efficiently convert the steam’s pressure into rotational energy.

Drivetrain and Paddle Wheel

The drivetrain in a candle steamboat is relatively simple. It connects the piston and cylinder to the paddle wheel in order to transfer the power from the expanding steam to the rotation of the wheel.

The piston is connected to a crankshaft via a connecting rod. As the steam pushes the piston up and down, this motion is translated into a rotary motion in the crankshaft. The crankshaft is connected via gears or a drive belt to an axle that drives the paddle wheel.

The paddle wheel itself consists of a number of paddle blades radiating out from a central hub. The whole wheel sits partially submerged in the water. As the axle turns due to the power from the crankshaft, the paddle wheel rotates through the water. The paddle blades push against the water, producing thrust to propel the boat forward.

The paddle wheel is designed to be large enough to generate sufficient thrust, but small enough to avoid excessive drag. The number and shape of the paddle blades can be optimized for efficient power transfer from the steam engine to the water. Overall, the drivetrain and paddle wheel work together to translate the reciprocating motion of the piston into smooth rotational motion that drives the boat forward.

Steering Mechanism

Candle steamboats use a simple rudder design for steering the boat. The rudder is a flat piece of wood or metal attached vertically to the stern (back) of the boat. The bottom of the rudder extends into the water.

The rudder is connected by ropes or chains to a steering mechanism, usually a wheel or tiller, on the deck of the boat. When the steering mechanism is turned left or right, it pulls on the lines connected to the rudder. This causes the rudder to angle left or right.

As water flows past the angled rudder it creates pressure and drag that pushes the stern of the boat in the opposite direction. This allows the rudder to steer the boat left or right. The angle of the rudder controls how sharply the boat turns.

Having a functional rudder is critical for allowing candle steamboats to change direction and navigate around obstacles. The simple mechanical design is powered entirely by the force of the water flowing past it.

Efficiency

While charming and nostalgic, candle steam boats have some inherent efficiency issues compared to modern power boats. The small flame and boiler setup of a candle boat limits the amount of usable energy that can be extracted. This restricts both the speed and operating duration of the boat.

The efficiency of converting heat to motion in the piston and cylinder mechanism also has room for improvement. Significant energy is lost as waste heat. More advanced engine designs in modern boats can utilize the fuel’s energy far more effectively.

The simplicity of the candle boat comes at the cost of performance. But for casual recreational use, where appearance and novelty are priorities, the compromise may be worthwhile. Just don’t expect to win any races against more powerful motor boats.

Use Cases

Candle steam boats have primarily been used for hobbyist and novelty purposes rather than as a practical means of transportation. Their small size and low power output makes them impractical for most real-world applications. However, they can serve as interesting decorative pieces or as educational toys to introduce people to the concept of steam power.

One of the most common uses of candle steam boats is as toys for children or hobbyists. These boats are often built as miniature models and powered by a small candle to propel them across a tub or pond. Their simple operation and charming appearance makes them appealing as tabletop novelties or bathtub diversions for kids.

Candle steam boats also find use as decorative items for centerpieces, holiday displays, or mantlepieces. Their old-fashioned asthetic and gentle movement from the flickering candle can add ambience to a setting. Collectors may appreciate finely crafted models as part of a nautical display.

In classrooms or museums, working candle steam boat models can help demonstrate the power of steam in a hands-on, interactive way. Watching the candle heat the boiler to move the pistons and wheel can bring steam technology to life for students.

While not used for transportation, candle steam boats have provided entertainment and education in a variety of settings as novel toys and demonstrations of basic mechanical and scientific principles.

Similar Designs

There are various other boats that use an external combustion heat source and steam power, similar to the candle steamboat. Here is an overview and comparison to the candle boat design:

Sterling engines were popular in the late 1800s for powering small boats. They use an external flame heating a closed system with air, generating power from expansion and contraction of the gas. More efficient than candle boats, but more complex in design.

Alcohol burner boats use a wick lamp fueled by alcohol. The lamp boils water to power a steam engine. Simple and efficient like candle boats, but fuel is slightly more dangerous and expensive than wax.

Solar steam boats use focused sunlight as the heat source for a steam engine. Highly efficient and renewable, but dependent on sunny weather. More complex mirror and boiler systems required.

In comparison, candle steamboats are unique in their simplicity and accessibility. Using just a tea light and tin can, they can be easily built at home as educational projects. Their basic wick and water design provides a direct demonstration of steam power.

Conclusion

In summary, candle steam boats are a fascinating way to harness the power of steam and use simple parts to create motion. The key elements are the candle as a heat source, the boiler to heat water into steam, the piston and cylinder to convert steam pressure into mechanical movement, and the drivetrain and paddle wheel to propel the boat forward. While not the most efficient design compared to modern steam engines, candle boats demonstrate how clever use of basic materials can power functioning miniature machines.

Candle steam boats serve as an enjoyable hobbyist project and educational model of steam power in a compact package. Their charming, old-fashioned aesthetic evokes the early days of steam technology. With some careful construction, these little boats can chug along surprisingly well on a wisp of candle flame. Though not built for speed or heavy use, candle steam boats are a quaint example of small-scale steam propulsion.