Why Are They Called Wicks?

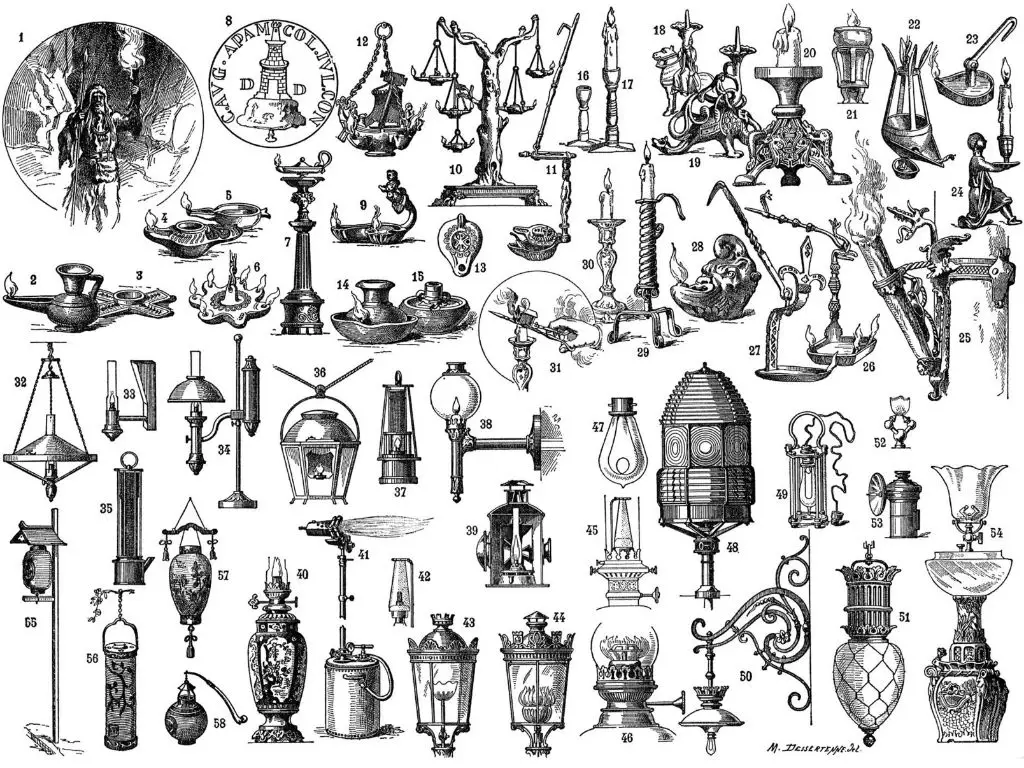

Lighting devices such as oil lamps and candles have relied on wicks for centuries to help control and distribute the flame. Wicks are the cord, yarn, or fabric that carries fuel via capillary action to the flame in oil lamps and candles. Early lighting devices used natural materials like papyrus, flax, and other fabrics as wicks.

The first lamps using wicks appeared over 70,000 years ago during the Paleolithic era. These early wicks were likely made of materials like moss, plant fibers, or animal hair. The ancient Egyptians advanced wick lamps by using linen and papyrus fibers braided into wicks. Wicks allowed lamps to burn oil and tallow efficiently for light and cooking.

The ancient Romans further improved on lighting by creating enclosed oil lamps made of pottery or bronze. These lamps used wicks to draw oil to the top where it could burn brighter. Candles also emerged around this time, utilizing wicks dipped in tallow or beeswax. For centuries, candle and oil lamp wicks represented the primary portable illumination sources for most people.

Definition of a Wick

A wick is a thin piece of string or fiber that is used in items like candles, oil lamps, and Zippo lighters to draw up fuel through capillary action and help sustain the flame. The purpose of the wick is to bring fuel to the flame so it can keep burning. As the fuel gets used, the wick absorbs more from the reservoir and delivers it to the flame. This allows the candle, lamp or lighter to keep providing light or heat as long as fuel remains.

In candles specifically, the wick is placed in the center and surrounded by wax or another solid fuel. As the flame melts the wax near it, the wick absorbs the liquid wax and brings it up to the flame so it can keep burning. The capillary action of the wick keeps just the right amount of fuel supplied to the flame. This allows the candle to burn slowly and evenly until all the wax is used up. The wick is a simple but vital component that enables items like candles to work.

Source: https://96north.com/what-can-you-use-as-a-wick-for-a-candle-a-comprehensive-guide/

Early Wick Materials

The earliest wicks were made from readily available natural materials like flax, cotton, hemp, and rushes. These fibrous materials were twisted or braided together to create a cord that could draw up melted wax through capillary action. According to the Smith College Museum of Ancient Inventions, “Wicking can be made from almost any kind of fiber; one of the most common in early days was loosely spun cotton” (Source). The History of Candles website notes that early Chinese candles used rice paper for the wick (Source).

Beeswax was also commonly used in early candlemaking. Beeswax is a natural wax produced by honey bees that has a high melting point. It could be formed into taper candles and lit without the need for a separate wick. The beeswax itself acted as both the fuel and wick for the candle. However, most other candle waxes like tallow, whale fat, and paraffin were too soft to be self-wicking. So a fiber wick was essential for proper burning.

Advancements in Wick Technology

Wicks evolved significantly over the centuries as new materials became available. Early wicks were commonly made from plant fibers like flax or cotton. These primitive wicks produced a lot of smoke and required frequent trimming. In the 18th century, experiments with braiding and weaving wicks led to major improvements in burning quality. By 1850, most wicks were cotton cords tightly braided or woven for a brighter, smoke-free flame (Candlewic).

Later advancements like the self-trimming wick were revolutionary. Invented in 1841, the self-trimming wick contained a thin metal coil that contracted as the candle burned, keeping the wick trimmed to an optimal length (Wikipedia). This innovation allowed candles to burn cleanly without any effort. It paved the way for longer lasting and more practical candles.

Today, wicks are available in a huge variety of sizes and materials like cotton, hemp, wood, and paper. Wick technology continues to advance, striving to produce the perfect flame in terms of brightness, height, smoke production, and more.

How Wicks Work

Wicks work through a phenomenon called capillary action. Capillary action describes the ability of a liquid to flow against gravity in narrow spaces such as small tubes, pores, or gaps between fibers. It occurs because of the intermolecular forces between the liquid and the surrounding solid surface.

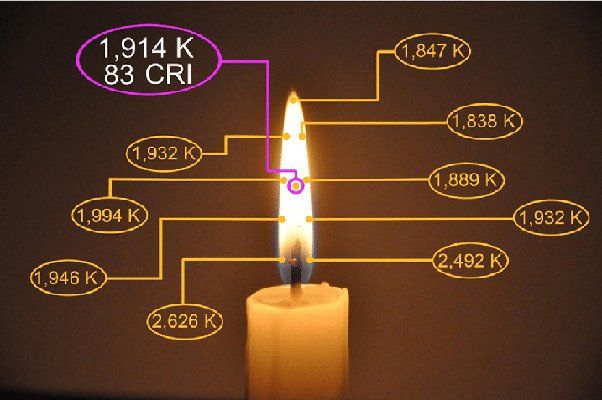

In a candle, the wax melts into a liquid fuel that is then drawn up through the narrow spaces inside the braided or twisted strands of the wick fiber. The capillary action creates a continuous flow of liquid fuel up the wick to feed the flame. This allows the wax to be vaporized for continuous burning. The wax gets consumed gradually as it transforms from solid state to liquid and finally to gaseous vapor.

According to research from physics.stackexchange.com, the dimensions of the wick determine how well it attracts the melted wax via capillary action. A wider wick will have larger pores and gaps between fibers, causing a greater capillary effect to draw wax upward. However, a wick that is too wide can create problems like dripping, tunneling, or an uneven burn.

Wick Design Considerations

The design of the wick is crucial for optimal candle performance. Three key factors to consider are wick width, braiding, and waxing.

Wider wicks tend to burn hotter and brighter, but also faster. Narrower wicks burn slower and cooler. Finding the right wick width for a given wax and candle size is important to achieve an even, consistent burn. According to research from NASA, wicks that are too wide can cause “thermal runaway and eventual burnout of the heated wick” (Gerrels, 1971).

Braided or plaited wicks help the wax melt and draw up into the wick through capillary action. The braiding creates small channels for the melted wax to move through. Studies have found that combining screen wire mesh with lengthwise grooves in the wick can enhance evaporation and capillary action (Park, 2021).

Waxing or priming wicks before use can allow for a more even burn. The wax coating helps the wick initially draw up melted wax. Unwaxed wicks may lead to an uneven start to the burn. Properly waxed wicks help ensure smooth, consistent burning.

Modern Wick Materials

Today, most wicks are made from synthetic materials like nylon and polyester rather than natural fibers like cotton. These modern synthetics have surpassed earlier wicking materials in many ways.

Nylon is now the most popular wick material due to its strength, durability, and excellent wicking capabilities. The fibers are designed to maximize capillary action, rapidly drawing fuel up through the wick. This results in a faster light time and improved combustion.

Polyester is another favored synthetic wick material. Polyester wicks are flame-resistant and tend to hold their shape well over time. This makes them a good choice for applications like oil lamps, tiki torches, and citronella candles where the wick needs to stand up to weather and repeated use.

Rayon and other semi-synthetic wick materials strike a balance between natural and synthetic properties. They often incorporate cotton or wood pulp with synthesized polymers to create a soft, flexible wick with good absorption. These materials work well for jar candles and other applications where a bit of flexibility is desired.

Thanks to advancements in materials science, wick engineers today have a wide array of synthetic options to create high-performance wicks tailored to nearly any application. These modern wicking materials outperform their natural fiber predecessors in most every way.

Specialized Wick Types

There are several specialized types of wicks designed for different candlemaking needs:

Gelled candle wicks are made to be used in gel candles, which use gelled fuels like mineral oil or vegetable oil gel rather than standard wax. These wicks are designed to curl and release properly when burning gel fuels. Common materials for gelled wicks include paper and cotton (source).

Scented wicks are infused with fragrances or essential oils so they release aroma as they burn. They allow candlemakers to add scent without fragrancing the wax. Popular scented wick options are beeswax and hemp wicks (source).

Wooden wicks make a crackling sound as they burn. Wood flakes are embedded into a cotton wick, providing an audible and visual effect. Wooden wicks come in various wood types like bamboo, oak, and cedar (source).

Wick Manufacturing Process

Wicks are mass produced in factories using specialized machinery and techniques to create consistent, high-quality wicks at scale. The production process involves taking raw materials like cotton, paper, or linen and transforming them into finished wicks through stages like twisting, waxing, and adding metal sustainer tabs.

The process starts by taking natural fibers like cotton, hemp, or linen and twisting or braiding them together into a cord, sometimes along with paper or other strengthening fibers. These cords are then coated in wax or paraffin to make them burn slower and more evenly. Tabs made of zinc or tin are crimped to the bottom of the wick to hold it upright in the candle wax.

Modern wick manufacturing uses automated braiding machines, wax rollers, and crimping presses to produce wicks efficiently at high volumes. Quality control checks are conducted during production and on finished wicks to ensure proper burning specifications. The wicks are cut to consistent lengths, bundled, and shipped out to candle makers and crafters.

Through this standardized process of braiding, waxing, tabbing, and cutting fibers, wick manufacturers are able to produce reliable, high-performance wicks at the scale needed to supply a global candle market.

Sources:

https://candle-shack.com/blogs/all-blogs/wick-manufacturing

Conclusion

Candle wicks have come a long way since their early beginnings thousands of years ago. Ancient civilizations relied on simple wicks made from materials like papyrus, flax, and palm to provide light and allow candles to burn. As technology advanced, so did wicks, evolving from crude bundles of fiber to the finely crafted cotton, paper, and fiber wicks we know today.

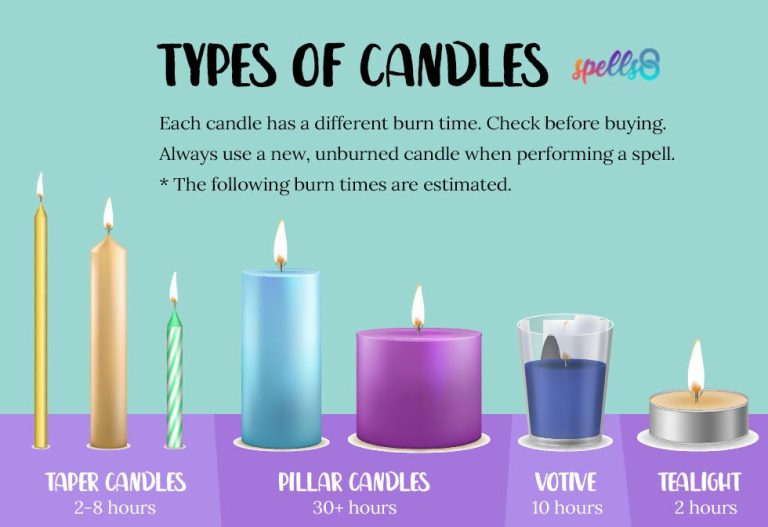

Modern wicks are engineered for optimal performance, utilizing materials like zinc and tin to help regulate heat flow. Specialized wicks have been developed for different types of candles, from votives to pillars to container candles. Wick technology continues to advance as candlemakers innovate new solutions.

But while the materials and engineering have changed dramatically over time, the purpose remains the same. Wicks draw fuel to the flame, enabling candles to provide gentle, natural light. Just as ancient civilizations relied on candles to illuminate their lives, we continue to enjoy the warm glow of candlelight today. Wicks make this simple pleasure possible.