What Wick Should I Use For Beeswax Candles?

Choosing the right wick is crucial for making high-quality beeswax candles that burn cleanly and efficiently. The wick acts as the fuel delivery system, drawing melted wax up to the flame. If the wick is too small, the flame will be weak and produce smoke. If the wick is too large, the flame may get out of control. The goal is finding the optimal wick that allows the wax to burn completely so there is no wasted wax or excess smoke.

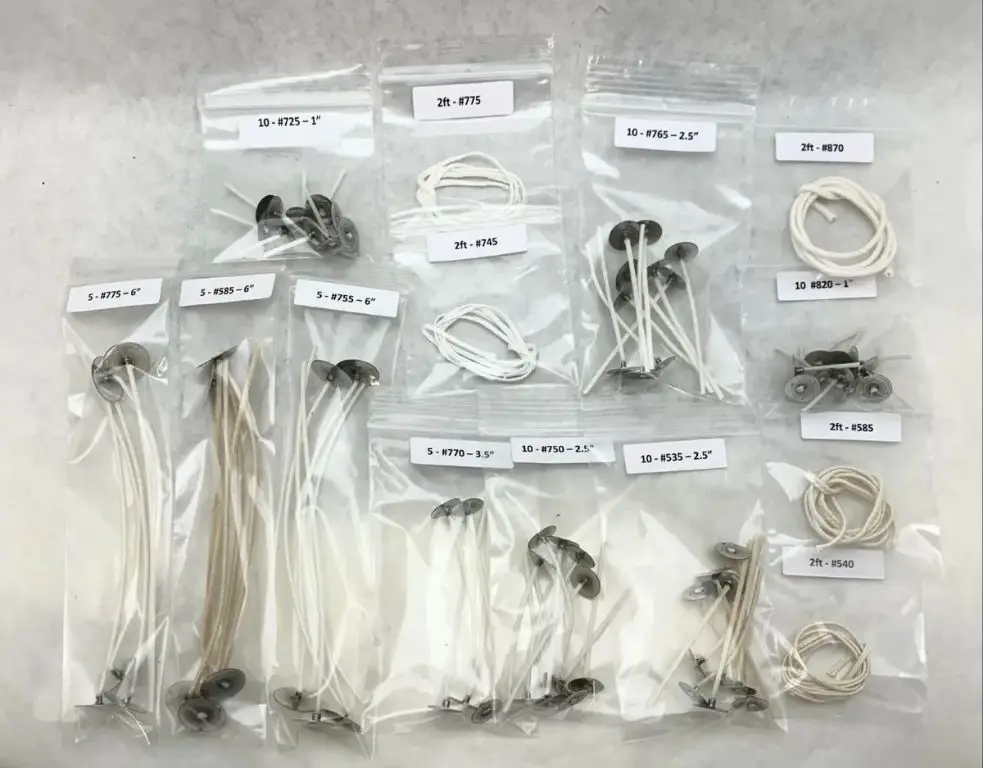

When selecting a wick for beeswax candles, there are several key factors to consider: wick material, wick size/diameter, whether it is braided or twisted, pre-tabbed vs plain, testing wicks, choosing by candle size, choosing by wax type, and considering specialty wicks. Taking the time to evaluate these aspects and test different wicks will ensure you end up with great quality beeswax candles that burn evenly from start to finish.

Wick Materials

The most common materials used for candle wicks are cotton, wood, paper, and zinc or tin cores. According to https://candles.org/elements-of-a-candle/wicks/, cotton is one of the most popular wick materials due to its ability to bend as it burns. Cotton can be braided or twisted into wicks of various thicknesses. Wooden wicks are also common, made from materials like bamboo. They produce a subtle crackling sound as they burn. Paper wicks are another option, made from thin paper that is rolled or braided. Zinc or tin cored wicks feature a thin metal core surrounded by cotton or other fibers. The metal helps the wick stand upright and burn evenly.

Wick Size

The diameter of a wick plays a critical role in candle performance. Wick size impacts the melt pool size and burn rate. Thicker wicks allow the candle wax to melt quicker and the melt pool to become larger due to the higher flame. Thinner wicks produce a smaller melt pool and slower burn rate because less heat is generated.

As a general rule, smaller diameter wicks (like CD 4) are best for containers 2″ or less in diameter. Medium wicks (CD 6) work well for containers 2-3″ diameter. Use larger wicks (CD 8-10) for containers 3-4″ in diameter. Jumbo wicks (CD 12+) are ideal for pillars and large containers over 4″ diameter.

Testing different wick sizes in your specific wax and container is recommended to find the optimal melt pool for performance and safety. The wick should not drown or smoke. Follow manufacturer guidelines on suggested wick sizes. (Source: Wick Guide – Find The Right Candle Wick For Your Candles)

Braided vs Twisted Wicks: Pros and Cons

When choosing a wick for beeswax candles, you’ll find that wicks generally come in either a braided or twisted style. Both have their advantages and disadvantages:

Braided Wicks:

– Braiding gives the wick more structural integrity to stand upright as the candle burns.

– The flat shape gives a slightly larger surface area for the flame.

– Braided wicks tend to be stiffer and may move less as the candle burns.

– The texture of braided wicks promotes an even burn.

– However, the flat shape can create more soot on the melt pool as the flame gets close to the end.

Twisted Wicks:

– The twisted shape promotes a spiral flame pattern that may give off less soot.

– They flex more easily as the candle burns down.

– The spiral shape can lead to an energetic flame that releases more fragrance.

– But the round shape gives a smaller surface area for the flame.

– Twisted wicks may bend over more easily as they get shorter.

Test wicks of each style to see which performs best for your particular beeswax and candle size. Many candle makers use a combination of braided and twisted wicks depending on the needs of each candle.

Pre-Tabbed vs Plain Wicks

A pre-tabbed wick is a wick that has been pre-primed with a coating of beeswax or paraffin wax. This coating allows the wick to catch and hold the flame faster when the candle is first lit. The purpose of pre-tabbed wicks is to help candles achieve full melt pool faster and prevent tunneling. The pre-applied wax coating acts as a “headstart” for the capillary action that draws wax up the wick. This allows the wick to burn hotter from the very beginning before the candle’s own wax pool has formed (CandleScience).

With a plain wick that has no pre-coating, the candle may struggle to form a full wax pool until the candle has burned for a while. This can lead to uneven burning and tunneling. The pre-priming on pre-tabbed wicks helps avoid this issue. Pre-tabbed wicks are especially useful for large candles, pillars, or candles with a high percentage of oils that are slower to melt. The pre-coating gets the wick hotter faster to form the melt pool quickly (JarStore).

Wick Testing

Wick testing is an essential step when making beeswax candles to ensure proper wick performance and an ideal burn. Testing allows you to evaluate factors like the flame height, melt pool diameter, burn time, and more before fully committing to a wick type and size.

Since beeswax has a high melting point compared to other waxes like paraffin, it’s crucial to test wicks specifically with beeswax before production. The thickness of beeswax and its high natural content of saturated fats means it requires a larger wick than other waxes. Testing helps determine the right wick to provide adequate heat to melt the wax pool and give a complete burn. Proper testing also prevents issues like tunneling, mushrooming, drowning, and more.

Choosing By Candle Size

One of the most important factors in choosing the right wick is matching it to the proper candle diameter. Using a wick that is too small for the candle diameter can lead to poor wax pooling and tunneling. A wick that is too large can create overly high flames and sooting.

As a general guideline from CandleScience, for small candles with a diameter under 2 inches, cotton core wicks like CD 5, 7, and 9 work well. For candles 2-3 inches wide, CD 10, 12, and 14 are recommended. Medium candles 3-4 inches in diameter pair best with CD 16, 18, and 20 wicks. Finally, for larger pillar candles and containers 4 inches and above, braided wicks like HTP 104 and HTP 105 are ideal.

Lonestar Candle Supply also provides the following wick recommendations based on candle diameter:

- X-Small containers up to 1.5 inches wide – CD 5 or 7

- Small containers 1.5 – 2.25 inches wide – CD 7, 9, or 10

- Medium jars 2.25 – 3 inches wide – CD 10, 12, or 14

- Large jars 3 – 4 inches wide – CD 16, 18, or 20

- Extra-large containers over 4 inches wide – HTP 104 or 105

Testing different wicks is recommended to find the best fit for a particular wax and fragrance blend. But using candle diameter as a starting point helps narrow down the options.

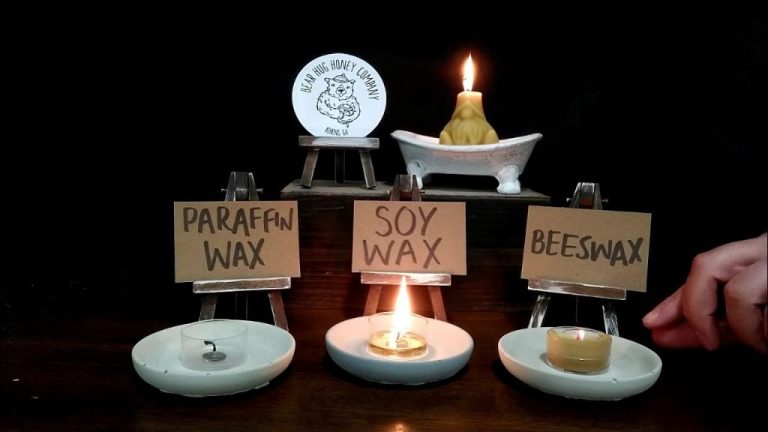

Choosing By Wax Type

When selecting a wick for beeswax candles, one of the most important considerations is the type of wax being used. Beeswax has distinct properties that impact how it absorbs and releases heat. To get a good burn, the wick needs to be tailored for beeswax specifically.

Experts recommend using square braided cotton wicks for beeswax candles. The cotton fibers provide excellent capillary action to soak up the wax, while the square braid helps the wick stay rigid and upright as the wax melts. The braiding also allows the wick to curl and self-trim, avoiding excess smoking.

Pre-tabbed square braided wicks, where the base of the wick is compressed for stability, are ideal for container candles made from beeswax. Plain square braided wicks work well for freestanding beeswax pillar candles.

Avoid using zinc core and paper core wicks intended for paraffin wax, as these are too stiff and thick for beeswax. With the right braided cotton wick, you can get the best burn performance from your natural beeswax candles.

Specialty Wicks

Many candle makers want to use specific waxes like beeswax or soy wax, which require specialty wicks designed for those wax types. Lone Star Candle Supply offers options like 100% cotton wicks for beeswax candles since cotton fibers soak up the wax well. They also have eco-friendly hemp wicks that are great alternatives for soy candles. Other specialty wicks include wooden wicks from Wholesale Supplies Plus which crackle when lit to provide a natural, cozy ambiance. Wicks made of paper, zinc, or tin may also be used for gel wax or beeswax for a clean, even burn.

When working with natural waxes like beeswax, look for braided cotton or hemp wicks that have excellent wax absorption. These natural fibers provide the capillary action needed for beeswax to melt and travel up the wick. Cotton square braids are ideal for container candles while cotton cored wicks work well for pillars and votives. Test wicks to ensure proper melt pools and burn times.

Conclusion

When choosing a wick for beeswax candles, there are several key factors to consider. The wick material, size, braid type, and pre-tabbing all impact how the candle will burn. Testing different wick types with your specific beeswax blend will help determine the best option. For most beeswax pillar candles, a medium-sized square braided cotton wick works well. Using the manufacturer’s wick recommendations for the candle diameter is a good starting point. Pre-tabbed wicks help anchor the wick and promote an even burn. Specialty wicks like wood and paper cored wicks add crackling and aromas, but may require more testing. The goal is finding the right wick that provides a full melt pool for complete wax consumption without producing excess soot or smoke. With testing and experience, the ideal wick for a clean, long-lasting beeswax candle burn can be achieved.