What Is Another Name For Paraffin Wax?

Introducing Paraffin Wax

Paraffin wax, also known as petroleum wax, is a soft, colorless solid derived from petroleum, coal, or oil shale that consists of a mixture of hydrocarbon molecules containing between twenty and forty carbon atoms. It is solid at room temperature and begins to melt above approximately 37°C (99°F) (Wikipedia, 2022).

Paraffin wax is odorless and tasteless. It is insoluble in water, but soluble in ether, benzene, and certain esters (Britannica, 2022). Paraffin wax is available in various grades ranging from a very hard and brittle wax to a softer, more pliable, sticky material (Paraffin Wax Co, 2022).

Some of the most common uses of paraffin wax include candle-making, as a lubricant, to make wax paper, in cosmetics, for art modeling, and more. It is also commonly used in medicine for applications like physiotherapy treatments through paraffin baths. Paraffin wax has a wide variety of industrial applications, ranging from electrical insulation to produce coatings and food packaging.

Other Common Names for Paraffin

Paraffin wax goes by many other common names, including:

- Kerosene – This clear, thin, odorless liquid is also known as lamp oil and is obtained from the distillation of petroleum. Kerosene is sometimes used as a synonym for paraffin wax, but it is a specific distillate of crude oil. [1]

- Mineral oil – A highly refined petroleum oil used industrially and medicinally. Mineral oil is a liquid form of paraffin wax. [2]

- Petroleum jelly – A semi-solid mixture of hydrocarbons obtained from petroleum. It has a thick, gelatinous texture and is commonly used in skin care products. Petroleum jelly is sometimes used interchangeably with the term paraffin wax. [3]

Overall, paraffin wax shares similarities with and can be referred to as petroleum-derived hydrocarbons like kerosene, mineral oil, and petroleum jelly. However, paraffin wax has its own unique chemical composition and properties separate from these other common names.

[1] https://en.wikipedia.org/wiki/Kerosene

[2] https://www.britannica.com/science/mineral-oil

[3] https://www.britannica.com/science/petroleum-jelly

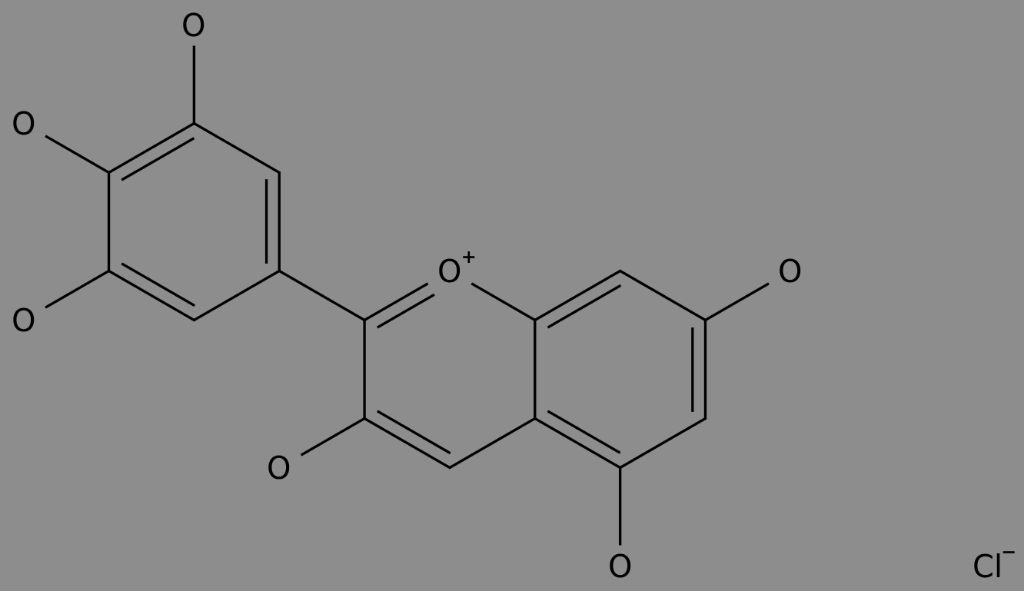

Chemical Composition

Paraffin wax is a chemical product made from petroleum.[1] It consists of a mixture of hydrocarbon molecules containing between 20 and 40 carbon atoms, with the chemical formula CnH2n+2. The molecules are alkanes, which means they consist entirely of hydrogen and carbon atoms linked together in straight chains with no branches or rings.[2] The most common alkane molecules in paraffin wax are octacosane (C28H58), hexatriacontane (C36H74), pentatriacontane (C35H72), and tetratetracontane (C44H90).

The varying chain lengths contribute to paraffin wax’s unique physical properties. The longer hydrocarbon chains result in a higher melting point, while the shorter chains keep the melting point low enough for practical applications.[2] The mixture of chain lengths also gives paraffin wax its waxy consistency and flexibility when warm. Overall, the chemical composition allows paraffin wax to transition between solid and liquid states within a convenient range of temperatures.

[1] https://en.wikipedia.org/wiki/Paraffin_wax

[2] https://www.sciencedirect.com/topics/chemical-engineering/paraffin-wax

Manufacturing Process

Paraffin wax is derived from the distillation of crude oil. Crude oil contains thousands of hydrocarbons, and the distillation process separates these compounds by their boiling points. The heavier hydrocarbons with high boiling points, such as paraffin wax, are separated and collected during fractional distillation.

The raw paraffin wax extracted during fractional distillation contains many impurities like oil and tar residues. It undergoes a purification process called solvent dewaxing to remove these impurities. In solvent dewaxing, the raw wax is dissolved in solvents like MEK (methyl ethyl ketone) which dissolve the oil, leaving behind dissolved wax. The dissolved wax is then recovered from the solution by chilling, filtration or evaporating the solvents. This produces purified paraffin wax ready for commercial use.

Paraffin wax was first produced commercially in the 1860s. Today, it is mass-produced globally by the petrochemical industry. The leading manufacturers are in China, South Korea and India. In 2020, the global paraffin wax market was valued at USD 6.97 billion.

References:

https://en.wikipedia.org/wiki/Paraffin_wax

https://blendedwaxes.com/blog/what-is-paraffin-wax/

Physical Properties

Paraffin wax is typically a white or colorless solid substance at room temperature with some variations depending on the manufacturing process. The melting point of paraffin wax ranges between 46-68°C (115-154°F) (Wikipedia). The density of paraffin wax is around 0.9 g/cm3 making it less dense than water (ChemicalBook).

The color, melting point, and density can vary slightly depending on the oil feedstock and manufacturing process used to produce the paraffin wax. But in general, it is a white or colorless, low density solid that melts at moderately warm temperatures.

Common Uses

Paraffin wax has various common uses, but three of the most prevalent are in candles, cosmetics, and lubricants.[1]

Candles: Paraffin wax is the most commonly used wax for candles. It is inexpensive, burns cleanly, and holds fragrance oils well. The wax helps the candle maintain its shape as it burns and produces minimal soot or residue.

Cosmetics: In cosmetics, paraffin wax is often used in skin care products to help soften and moisturize the skin. It is a common ingredient in lotions, creams, lip balms, and hand creams. The wax forms a protective barrier on the skin and seals in moisture.

Lubricants: Paraffin wax is used as a lubricant in various mechanical applications where moving parts come in contact, such as ski plates, fishing line, and textile manufacturing. The wax helps reduce friction and prevent damage or wear to the moving parts.

Advantages of Paraffin Wax

Some of the main advantages of paraffin wax are that it is cheap, abundant, and highly customizable.

Paraffin wax is very inexpensive to produce, especially compared to other types of wax like beeswax. It can be efficiently manufactured from petroleum and coal residues, making it widely available and affordable. This is one reason paraffin wax is used for so many commercial products – it provides desirable properties at a low cost.

In addition, paraffin wax is easy to modify and blend with additives to achieve specific melting points, consistency, and other physical characteristics. Manufacturers can customize paraffin to meet the needs of certain applications, like making it harder or softer. This versatility makes paraffin an ideal base material for candle making, cosmetics, art supplies, and more. The composition and properties of paraffin wax can be finely tuned by blending it with mineral oil, fatty acids, or other substances.

Overall, the abundance, low cost, and customizability of paraffin wax make it advantageous for a wide variety of commercial and industrial uses.

Disadvantages

Paraffin wax has a few notable disadvantages. One of the main issues with paraffin wax is that it is not biodegradable. Since paraffin wax is a petroleum-based product, it does not break down easily in the environment (Source 1). This means that paraffin wax can persist in landfills for a very long time. The non-biodegradable nature of paraffin wax makes it problematic from an environmental standpoint.

Another disadvantage of paraffin wax is that it is flammable. Paraffin wax has a relatively low flash point of around 150 to 200°F (Source 2). This makes it easy to ignite if overheated or exposed to an open flame. Paraffin wax’s flammability makes it important to take precautions when melting or heating the wax. Proper ventilation, low temperatures, and avoiding sparks/flames are key when working with paraffin wax.

Alternatives to Paraffin Wax

While paraffin wax is commonly used, there are some alternative waxes that can be substituted in certain applications:

Beeswax – Beeswax is a natural wax produced by honey bees. It has a natural honey aroma and is commonly used as a substitute for paraffin wax in products like lip balms, lotions, and candles. Beeswax burns cleaner than paraffin wax. However, it is more expensive and has a lower melting point.

Soy Wax – Soy wax is made from hydrogenated soybean oil. It is a renewable and sustainable resource. Soy wax burns slower and cleaner than paraffin wax. It is commonly used in candles and other cosmetic products as an eco-friendly alternative. However, soy wax is typically more expensive than paraffin wax.

Gelatin – Gelatin can be used as a substitute for paraffin wax, especially in food products. Gelatin forms a glossy coating that helps food retain moisture and shape. However, gelatin melts at a much lower temperature than paraffin wax.

Conclusion

In summary, paraffin wax, also known as paraffin or paraffinum liquidum, is an odorless, tasteless petroleum by-product commonly used in cosmetics, food, and candle making. Though the history of paraffin wax dates back thousands of years, today it is mass-produced through advanced oil refining and distillation processes. Key properties like its plasticity, water repellency, and high melting point make it useful across industries. While paraffin wax continues to have many applications, concerns around its environmental impact have led to the rise of alternatives like beeswax, soy wax, and palm wax. Looking ahead, innovative uses of paraffin wax will likely focus on improving sustainability and developing effective substitutes from renewable sources. Ultimately, paraffin wax remains an important and versatile material, though the future may see it used more judiciously.