What Is A Professional Candle Maker Called?

A professional candle maker is someone who creates candles as their main occupation or business. They have specialized skills, training, and experience in candle making, and produce high quality candles on a commercial scale. Professional candle makers may work independently selling their own candle brands, be employed by a candle company, or provide candle making services to clients.

In this article, we will explore the different names and terms used to refer to professional candle makers throughout history and in the modern candle industry.

History of Candlemaking

The history of candlemaking as a profession dates back thousands of years. Evidence shows that as early as 3000 BC, ancient Egyptians were making candles using rushlights and torches soaked in melted animal fat [1]. Around the same time, Chinese candlemakers were using rice paper for wicks and yak butter for the fuel source [2]. Candlemaking emerged independently across the ancient world as various civilizations found ways to extend light beyond daylight hours.

In early centuries, candlemaking was primarily done in homes rather than as a trade. Tallow candles made from beef or mutton fat were developed by the Romans beginning around 1000 BC [1]. Beeswax candles were introduced in Europe around the middle ages, providing a cleaner burning alternative to tallow. During the 18th century, spermaceti wax from sperm whales allowed higher quality candles to be mass produced. The 19th century saw paraffin wax emerge as a byproduct of petroleum refining, making candlemaking faster and more efficient.

Over time, candlemaking evolved from small homemade productions to become a respected trade practiced by skilled craftspeople. Dedicated candle shops began opening in England and France starting in the 13th century. Colonial American candlemakers were an important provider of light. Today, thousands of people around the world work as professional candlemakers, bringing centuries of artistry and tradition to the ancient craft.

Different Types of Candlemakers

Throughout history, there have been several types of professional candlemakers with different specializations:

- Chandler – A chandler is a general candlemaker who makes candles from various materials like tallow, beeswax, paraffin wax, soy wax, etc. They produce candles in many shapes and sizes.

- Wax Chandler – A wax chandler specifically makes candles from beeswax. Beeswax candles have a lovely natural honey aroma and are often used in churches and for aromatherapy.

- Taper Maker – As the name suggests, a taper maker crafts taper candles which are long, thin candles. Taper candles are commonly used for candlelit vigils and ceremonies.

- Votive Maker – A votive maker produces small votive candles which are short and wide. Votive candles are often used in candle holders and votive candle displays.

- Guild Chandler – Historically, a guild chandler belonged to the Worshipful Company of Chandlers in London. They produced high-quality beeswax candles.

Other types of specialized candlemakers may focus on decorative candles, scented candles, candles for specific occasions like birthdays or holidays, etc. Some may also make candle holders, candelabras, and other candle accessories.

Training and Education

To become a professional candlemaker, there are several important skills to develop. According to the Armatage Candle Company, some key skills include understanding wax chemistry, mastering wick science, learning color and fragrance blending, and developing design and packaging expertise (Source: https://armatagecandlecompany.com/blog/20-skills-every-candle-maker-should-master/). While some skills can be self-taught through practice and experimentation, taking formal classes, workshops or apprenticing with an experienced candlemaker can accelerate the learning process.

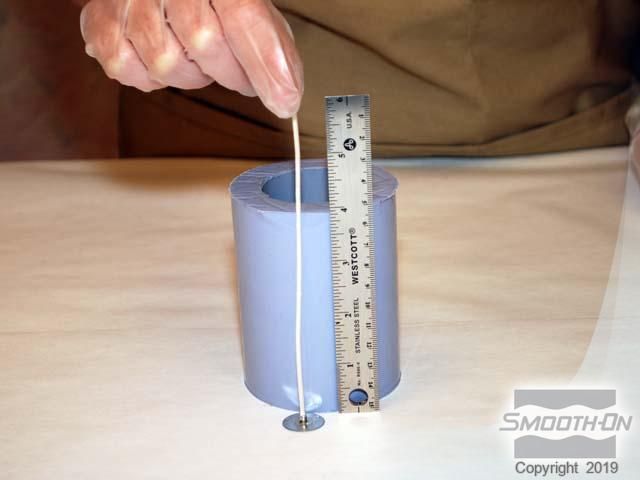

Many professional candlemakers start by taking candle making classes offered by local arts centers, craft stores or independent candle making studios. These hands-on classes cover topics like selecting waxes, wicks and fragrances, proper wick sizing, pouring techniques, essential safety practices, and finishing processes. After mastering basic techniques, more advanced classes can teach skills like creating original candle scents, experimenting with unique shapes and molds, developing branding and packaging, and running a candle business.

There are also longer-term certificate programs offered by some vocational schools and colleges. These intensive programs allow students to deeply explore candle chemistry, manufacturing processes, business operations, and innovative candle designs over the course of several months or up to a year. Graduates earn a certificate which signals their comprehensive candlemaking education.

While formal training is extremely valuable, continuous self-education through books, online learning, experiments, and connecting with other candlemakers is also crucial for honing skills over time. Most professional candlemakers view mastery of their craft as a lifelong learning process.

Day-to-Day Work

A typical day for a professional candlemaker involves a variety of tasks related to designing, producing, and selling candles. Some of the common day-to-day activities include:

Selecting and preparing candle wax – Candlemakers often start their day by preparing the wax they will use that day. This involves selecting the type of wax (soy, paraffin, beeswax, etc.) and melting and tempering it to the proper temperature.

Adding fragrance and color – Once the wax is prepped, the candlemaker will add fragrance oils and dye to create the desired scents and colors for their candles. They carefully measure out the fragrance and dye ratios.

Pouring candles – One of the main tasks is to pour the liquid wax into containers and molds to create the candle shape and form. Candlemakers pour multiple candles in batches during the production process.

Cooling and setting completed candles – After candles are poured, they need time to completely cool and set, which can take several hours. Candlemakers often go back and remove hardened candles from their molds and place them aside to finish cooling and curing.

Finishing and labeling – Finishing steps include trimming wicks, smoothing tops, adding labels, and attaching lids onto container candles. This finishing process helps ready the candles for sale.

Packing and shipping orders – Part of the job is fulfulling orders by wrapping, packing, and shipping out finished candle products to customers and retailers.

Cleaning work areas – Candlemaking involves dealing with wax spills and drips, so cleaning the work tables, floors, equipment, and tools is an ongoing task.

Developing new candle designs – Many professional candlemakers spend time coming up with new candle scents, colors, and packaging ideas to expand their product line.

In summary, professional candlemaking involves a range of daily activities related to candle production and business operations.

Salary and Job Outlook

Professional candlemakers can expect to earn an average salary of $45,890 per year according to data from Glassdoor.com (https://www.glassdoor.com/Salaries/candle-maker-salary-SRCH_KO0,12.htm). The salary range typically falls between $33,000 for entry level positions up to $70,000 for experienced candle makers and business owners. According to Zippia.com, the number of candlemaker jobs in the US is approximately 12,958 (https://www.zippia.com/candle-maker-jobs/).

The job outlook for professional candlemaking is strong. According to ZipRecruiter data, contract candlemaking jobs pay nearly 25% more than the average salary (https://www.ziprecruiter.com/Salaries/Candle-Business-Salary). Candlemaking and candle retail businesses have grown significantly over the past decade as interest in handmade and artisanal products continues to rise. The candle industry is projected to reach $11.8 billion globally by 2027, presenting plenty of opportunities for professional candle makers and business owners.

Notable Professional Candlemakers

Throughout history, there have been many talented professional candlemakers who have helped advance and shape the art of candlemaking. Here are a few notable examples:

One of the most famous is Matthäus Merian, who lived from 1593 to 1650. He was a Swiss engraver and publisher who also worked as a professional candlemaker in Basel, Switzerland. Merian innovated candlemaking techniques and published books on the subject like “The Art of Candle Making” in 1631 (source: https://blog.onekingslane.com/cire-trudon-new-york/).

The French Trudon family pioneered many advances in candlemaking starting in the 17th century. Operating out of Paris, they were candlemakers to royalty and the Catholic Church for generations. Their company Cire Trudon is considered the world’s oldest candlemaker still in business today (source: https://blog.onekingslane.com/cire-trudon-new-york/).

In early American history, William Will was one of the first professional chandlers, or candlemakers, in the English colonies. He plied his trade as a candlemaker in Boston beginning in the 1630s. His candles were crucial before the advent of electric lights (source: https://blog.onekingslane.com/cire-trudon-new-york/).

Candlemaker Associations

There are a few notable professional associations for candlemakers in the United States:

The National Candle Association (NCA) is the leading trade association representing candle manufacturers and suppliers in the US. The NCA serves as an authority on candles and candlemaking and advocates on behalf of the candle industry. Membership includes manufacturers, raw material suppliers, retailers, and associated services. The NCA hosts an annual conference, provides industry research and statistics, and offers training programs.

The ScentsAbility organization provides vocational training, employment, and supportive services for individuals with disabilities to enable them to create high-quality, handmade scented candles. ScentsAbility helps candlemakers build skills and transition to competitive employment.

The Handcrafted Soap & Cosmetic Guild offers training programs, conferences, and resources specifically for handcrafted bath, body and candle businesses. The Guild allows candlemaking professionals to network and receive guidance on best practices.

There are also regional associations such as the Ohio Candle Makers and Soapers Association that provide education, networking, and support at a more local level.

Other Names and Terms

Professional candlemakers may also be referred to by other names and terms, including:

Candle artisan – This term emphasizes the creative and artistic nature of candlemaking. Candle artisans focus on handcrafting beautiful, unique candles (Source: https://www.wix.com/blog/candle-business-name-ideas).

Chandler – This is an older term that originally referred to someone who made candles and lanterns. Chandler comes from the Old French “chandelier,” meaning candle. In modern times, chandler is still occasionally used to describe professional candlemakers (Source: https://www.wordlab.com/candle-business-names/).

Wax worker – This highlights the hands-on work of shaping and forming wax involved in candlemaking. Wax workers are skilled in techniques like pouring, dipping, and molding to create candles (Source: https://www.brandroot.com/candle-company-name-generator).

Candlepreneur – A creative portmanteau blending “candle” and “entrepreneur,” this term emphasizes candlemaking as a business venture. Candlepreneurs own and operate their own candle company or brand (Source: https://www.brandroot.com/candle-company-name-generator).

Conclusion

Professional candle making is a specialized craft that requires expertise, creativity, and attention to detail. While in the past candle making was a common household skill, today it is primarily done by dedicated artisans who have undertaken formal training. These professional candle makers are known by various titles depending on their specific role and skills, but they share a passion for the art of candle making.

Whether they focus on hand-dipping, pouring, container candles, votives, or another specialty, professional candle makers combine science and artistry to produce beautiful, high-quality candles. Their work provides enjoyment, ambiance, and practical light sources for customers around the world. Though largely overshadowed by mass manufacturing today, the tradition of the professional candle maker lives on and continues to illuminate our lives.