What Are 3 4 Mistakes To Watch For When Making Soy Candles?

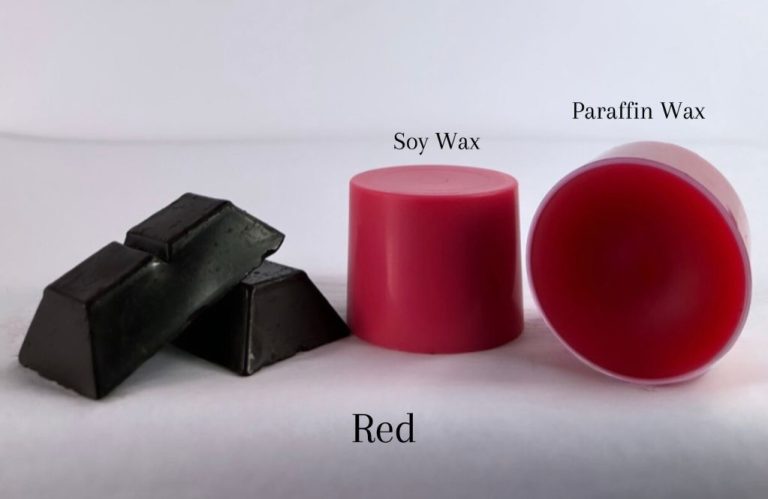

Using the Wrong Wax

One of the most common mistakes when making soy candles is using the wrong type of wax. Soy wax and paraffin wax have very different properties and require different wicking and pouring temperatures. According to Yolouie, “Paraffin wax and paraffin/soy blend candles burn faster than 100% soy wax candles and generate copious amounts of smoke when burned.”

100% soy wax candles burn slower and cleaner than paraffin or paraffin-soy blends. The wax composition directly impacts burn time, scent throw, and the overall quality of the finished candle. As Felinfach notes, “Soy wax candles and paraffin wax candles are two of the most popular types of candles on the market.” Using pure soy wax ensures proper melting, adhesion, and burning.

Be sure to use 100% soy wax marketed specifically for candle making. Paraffin wax or paraffin-soy blends will not deliver the same results as pure soy wax when making soy candles.

Improper Wick

Soy candles require the proper wick material and size in order to burn correctly. Using the wrong wick can lead to issues like tunneling, poor scent throw, smoking, or flames that are too high or low. Some common mistakes when choosing wicks for soy candles include:

Using a cotton wick when making soy candles. Cotton wicks tend to clog more easily in the softer soy wax, leading to poor burn and waste. How to Choose a Wick for Soy Candles recommends using wood or tin wicks instead for soy.

Using a wooden wick that is too thick for the diameter of the candle. Wood wicks need space around the flame for proper combustion. An oversized wick in a small candle will lead to soot and smoking. Refer to manufacturer’s guidelines for pairing wood wick sizes with jar diameters.

Using tin wicks in frosted or opaque containers. The metallic shine of tin wicks works best in clear glass containers, as the flickering effect is diminished if not visible.

Testing wick options before mass production is key. The width, type and material can all impact the final burn. Using the improper wick is a common mistake with soy candles that is easily avoided with experimentation.

Incorrect Wick Size

Choosing the wrong wick size for your soy candles can lead to major problems like tunneling, poor scent throw, and more. Wick size directly impacts how your candle burns by controlling the melt pool size and temperature.

Larger diameter wicks create a larger melt pool by allowing more wax to liquify at once. Smaller wicks have the opposite effect, creating a smaller melt pool that constrains the burn area. If your wick is too small for the diameter of your container, this will lead to tunneling where just a small hole burns down through the center of the candle. A wick that is too large can cause issues like full wicks, mushroom tops, and excessive soot.

To avoid problems, consult a wick sizing chart like the one provided by CandleScience to match your wick size precisely to your specific container diameter and wax type https://www.candlescience.com/learning/choosing-the-right-wick-size/. Testing wick sizes with sample candles is also recommended before making large batches.

Pouring at Wrong Temperature

One of the most common mistakes when making soy candles is pouring the wax at the wrong temperature. Soy wax needs to be poured within a precise temperature range to ensure proper setup and burn. According to Natures Garden Candles, the ideal pouring temperature for soy wax is between 135-140°F (source). If the wax is too hot, above 150°F, it can cause issues like sinkholes, poor adhesion, and an uneven top. Pouring below 130°F can lead to frosting, poor fragrance binding, and cracked tops. Use a thermometer to carefully monitor the temperature and maintain it within the optimal 135-140°F range as you pour the soy wax into containers. This will help avoid pouring at the wrong temperature, resulting in candles that don’t burn properly.

Insufficient Cure Time

One of the most common mistakes when making soy candles is not allowing enough cure time before burning them. Soy wax needs several days to cure and fully harden after being poured into containers. If soy candles are burned too soon, it can cause issues like poor scent throw, sputtering, tunneling, and an uneven melt pool.

During the curing process, soy wax finishes contracting and the candle becomes more dense. Curing allows time for any trapped air bubbles to find their way to the surface. As the soy wax cures, fragrance oils and essential oils also have time to fully bind to the wax. Rushing to burn an uncured candle risks releasing more of the scent at once instead of slowly over several burns.

A good rule of thumb is to allow soy candles to cure a minimum of 24-48 hours before lighting. Curing for 4-7 days is ideal if you want to maximize scent throw and achieve the best burn performance. Be patient and let soy wax candles properly cure first for the best results.[1]

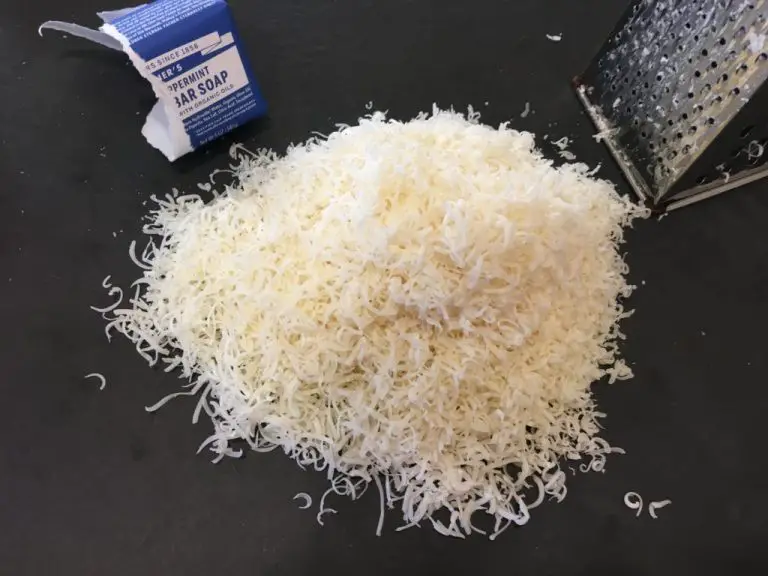

Using Dirty Containers

One of the most common mistakes when making soy candles is using dirty containers. Any residue, dust, oils, or soap left in the container can negatively impact how your candle performs.

Before pouring your soy wax, be sure to thoroughly wash and rinse your containers with hot water and dish soap. Pay extra attention to removing any oils or waxes left over from previous use. You’ll want the containers completely clean and dry before adding wax.

You should also avoid handling the interior of the glass too much after cleaning. Oils from your skin can transfer to the glass and cause wet spots or adhesion issues. Wearing gloves while preparing containers can help prevent this.

Taking the time to properly clean and dry your containers is an important step that is easy to overlook. But putting in that small effort will pay off through better looking, higher quality soy candles.

Inadequate Fragrance Oil

One of the most common mistakes when making soy candles is using an inadequate amount of fragrance oil. Soy wax has a natural scent that can overpower lighter fragrances if you don’t use enough fragrance oil in your candle. The general recommendation is to use 5-10% fragrance load for soy wax candles (1). This means using 0.5 – 1 ounce of fragrance oil per pound of wax. Going below 5% risks having a candle with little to no scent throw. Exceeding 10% fragrance load runs the risk of the fragrance not binding properly with the wax which can lead to fragrance “fall out” during the cure process.

When adding fragrance, it’s ideal to heat the wax to around 180-185F before mixing in the fragrance oil. This helps the fragrance fully incorporate into the melted wax. After adding the fragrance, stir gently for 1-2 minutes to ensure it’s evenly distributed before pouring the candles (2).

Testing different fragrance load percentages with your wax and specific fragrances will help you find the ideal amounts for your soy candles. But generally staying within 5-10% is recommended for optimal hot and cold scent throw.

(1) https://waxandwick.co/blogs/news/how-much-fragrance-oil-to-add-to-soy-wax

(2) https://www.scandinaviancandle.com/blogs/faq/how-much-fragrance-oil-to-use-in-your-candle

No Even Top

One of the most common mistakes when making soy candles is ending up with an uneven, bumpy top. This happens because soy wax cools and hardens more quickly than other waxes, so any imperfections in the top surface get locked in place before you can smooth them out. There are a few techniques you can use to help get a nice, flat candle top:

Using a heat gun is one of the most effective ways to fix an uneven top. Simply warm the wax gently and evenly with the heat gun to melt just the very top layer, then smooth it out with a knife or spatula before it hardens again. Be very careful not to overheat the wax or hold the heat gun too close. Go slowly and gently. See this guide for tips on using a heat gun to fix rough candle tops: https://www.candlescience.com/learning/candle-making-101-smooth-tops/

Pouring at the right temperature also helps achieve a smooth finish. Soy wax should be poured between 115-120°F to allow enough time to settle before it starts to set up. Pouring at temperatures that are too hot or too cold can cause an uneven surface.

Controlling the ambient temperature and airflow in your candle making space makes a big difference as well. Drafts and temperature fluctuations will cause the wax to cool and harden at uneven rates, creating texture on the top. Work in a still, draft-free space with a consistent temperature around 75°F.

Poor Labeling

Proper labeling is crucial for soy candles. The label provides important information to the consumer about ingredients, safety, and usage instructions. Follow these best practices for candle labeling:

- Include the company name, candle name/scent, and weight on the label. This helps identify the product and brand.

- List all candle ingredients. This allows consumers to check for allergens or irritants.

- Add safety warnings like “Keep away from children and pets” and “Keep away from flames or heat sources.” This educates about proper usage.

- Include usage instructions like “Trim wick to 1⁄4 inch before lighting” and “Discontinue use when 1⁄2 inch wax remains.” This prevents unsafe burning.

- Choose label materials that can withstand heat. Many paper and vinyl label adhesives can’t withstand the 150+ degree temperatures.

- Consider hang tags. These allow adding more labeling information and won’t heat up like container labels.

With comprehensive, compliant labeling, soy candle makers can avoid liability issues and create a polished, professional product. For more labeling tips, see Your Box Solution’s soy candle labeling guide.

Ignoring Safety

Soy candles are generally considered very safe. However, there are some basic safety precautions you should follow when burning any candle, including soy candles:

According to [1], you should always burn candles in a well-ventilated room and never leave a burning candle unattended. Keep candles away from drafts, vents, ceiling fans, and air currents, as these can cause the flame to tunnel or smoke [2].

Be very careful not to burn a soy candle for too long – stick to the manufacturer recommended burn time, usually 2-4 hours. Longer burn times can cause overheating and lead to potential fire hazards [3].

It’s also important to keep wicks trimmed to 1⁄4 inch to prevent smoking, tunneling, and ensure proper wax pooling [2]. Always make sure candles are placed on a heat resistant surface, out of reach of children and pets. Never move or touch a burning candle when wax is still liquid.

While soy wax itself is not considered toxic, any scented candle can potentially irritate those with asthma or allergies. Pregnant women may also want to be cautious around scented candles. Consider burning unscented soy candles if you have any health concerns [1].

Following basic candle safety rules will help ensure you can enjoy soy candles safely and avoid potential fire or health hazards.

[1] https://www.unplugsoycandles.com/pages/soy-candle-care

[2] https://tipsycandlecompany.com/tipsy-tips-safety/

[3] https://www.ctrivercandles.com/candle-care.html