Is Candle Making Cheap For Candles

Candle making has grown in popularity as a hobby in recent years due to the increased interest in sustainable, natural products and the satisfaction of creating something with your own hands. It provides an outlet for creativity and self-expression, and allows hobbyists to customize their candles with preferred scents, colors, and designs.

Making candles at home gives you control over the ingredients and materials used. Many hobbyists prefer to use soy wax, beeswax or other natural waxes along with cotton wicks and essential oils. The finished candles make great gifts or home decor. While there are some startup costs for supplies and equipment, the hobby can be as affordable as you choose to make it.

Cost of Candle Making Supplies

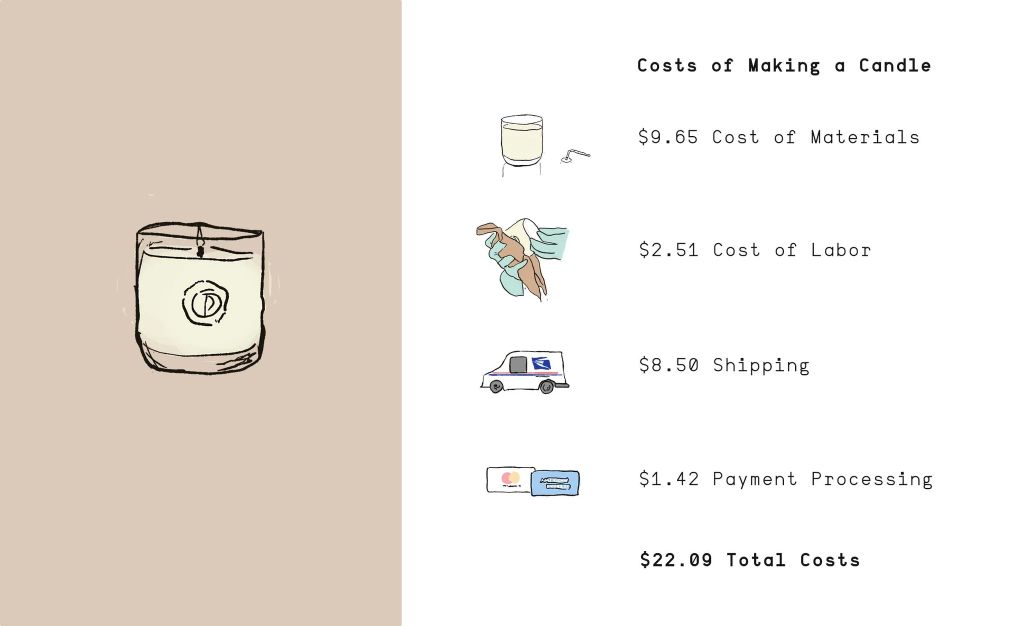

The main supplies needed for candle making include wax, wicks, fragrance oils, jars/containers, and dye. These ingredients can add up in cost rather quickly.

Wax is the biggest expense, with prices ranging from $1-3 per pound depending on the type. Paraffin is the most affordable at around $1 per pound. Soy wax costs $2-3 per pound and natural beeswax can be $3-6 per pound or more (source).

Wicks are inexpensive, usually $0.10-0.30 each depending on thickness. However, testing is required to find the right wick for each wax and jar combination (source).

Fragrance oils can range from $2-8 per ounce. Using 6-12% fragrance, a 16 oz candle would require 1-2 ounces of oil. Essential oils are more expensive at $10-30 per ounce (source).

Jars and containers have a wide range of prices, but glass canning jars are affordable at $0.50-2 each. More decorative vessels can cost $2-5 per piece.

Liquid candle dyes cost around $3-5 for a 1-2 oz bottle, which will color several pounds of wax. Pigment dyes are more economical but require an additive to blend with the wax.

Cost Comparison to Store Bought Candles

Several sources indicate that making candles at home is substantially cheaper than buying pre-made candles from stores. For example, a 22 ounce candle from Yankee Candle can cost around $30, whereas the same size homemade candle may only cost $5-10 in materials (Source: https://newhobbybox.com/reasons-diy-candles/). One analysis found that making homemade candles saves about 62% compared to buying candles online or in stores over the course of a year (Source: https://selkietraveller.com/the-truth-about-making-your-own-candles-is-it-worth-it/).

The general rule of thumb is that wholesale pricing for handmade candles is about 2 times the cost of materials, while retail pricing is 3-4 times the cost. This significant markup by retailers and brands allows homemade candle makers to undercut store pricing considerably (Source: https://www.reddit.com/r/candlemaking/comments/7yta2k/is_it_cheaper_to_make_or_buy_my_candles/).

In summary, the raw materials and labor for homemade candles cost a fraction compared to the high retail prices of store-bought, branded candles. Candle lovers can save 50% or more by making their own.

Factors Affecting Candle Costs

There are several key factors that affect the total cost of making candles at home:

Quantity Made – Making candles in larger batches generally lowers the cost per candle, as you can buy supplies in bulk and reuse molds. Making just a few candles at a time leads to higher per unit costs.

Quality of Supplies – Higher quality waxes, fragrances, wicks, and jars do cost more than lower quality options. Opting for premium supplies will increase the base costs. However, the higher quality can allow charging higher retail prices. Source

Complexity of Design – The more intricate the candle design, the more labor and supplies are required. Layered candles, ornate jars, complex scents, and hand-poured designs take more time and specialized materials. Simple pillar or votive candles are the least complex and cheapest.

Tips for Saving Money

Making candles at home can be an affordable hobby if you follow some tips for cutting costs. One of the best ways to save is by buying candle making supplies in bulk. Purchasing wax, wicks, fragrance oils, and containers in larger quantities will bring down the per-unit price. Buying a box of 100 pre-tabbed wicks rather than 10 at a time can make a big difference in the long run.

Reusing and repurposing containers from around the house is another money-saving strategy. Glass jars from food products like sauces and jams can be cleaned out and given new life as candle vessels. The same goes for tin cans, ceramic bowls, and other household items. Avoid anything with brand labels to give your homemade candles a more upscale, customized look.

Keeping the candle designs simple will also help lower material costs. Intricate multi-layer candles require more supplies and specialized equipment. Sticking to basic one-wick, single-fragrance pillar or votive candles streamlines the process and reduces waste.

Initial Startup Costs

The initial startup costs for beginning candle making can vary greatly depending on the scale of production. Some of the main expenses when first starting out include:

- Purchasing candle making equipment like wax melters, thermometers, wick bars, and molds which can range from $50 for basic supplies to $500 or more for larger professional equipment (source)

- Buying wax, wicks, fragrance oils, dyes, jars, and packaging materials. Expect to spend $200-$500 on initial inventory (source).

- A dedicated workspace for production and storage which could be $1500-$3500 per month if renting (source).

- Design and marketing expenses like logo design, website, and promotional materials which can cost $500-$1000 (source).

Overall, most candle making startups require an initial investment of $2000-$5000 to cover the core equipment, inventory, and operating expenses needed to launch production (source). This initial outlay can grow quickly for larger scale operations or more complex production.

Cost Per Hour of Labor

The time it takes to make candles can greatly impact the overall cost. From melting wax to pouring into containers and packaging finished candles, every step adds more labor hours. One source estimates candle making takes approximately 1-2 hours per pound of wax used (Blaze and Foam). So a 1 lb candle would take 1-2 hours of active work. At the federal minimum wage of $7.25 per hour, the labor cost per 1 lb candle could be $7.25 – $14.50. The more detailed the design or intricate the process, the more hours required.

For those doing candle making as a hobby or small side business, their hourly wage may be higher. The labor rate should be set based on their full-time earning potential. A rate of $15-25 per hour would not be unreasonable for skilled crafters. This results in a wider range of $15-$50 labor cost per 1 lb candle.

Automating parts of the process with molds and equipment can help increase efficiency and lower the hours per candle. But the initial capital costs must be weighed when investing in such improvements. Overall, labor represents a significant portion of total candle costs that must be tracked.

Quality Comparison

When it comes to quality, homemade candles often outperform store bought candles in a few key areas:

Burn time – Handmade candles typically have a longer burn time than factory-made candles. This is because homemade candles use quality wicks and more wax, resulting in candles that burn for up to twice as long as store-bought ones [1].

Fragrance – Homemade candles tend to have stronger, more authentic fragrances. Since they are hand poured in small batches, more fragrance oils are added relative to the amount of wax. Store bought candles often use synthetic fragrances that can smell artificial [2].

Appearance – The handmade process allows for a high degree of personalization when it comes to appearance. Homemade candles can have creative shapes, colors, labels, and decorations that set them apart from the uniform look of mass-produced store candles.

Satisfaction of Homemade

One of the best parts about making your own candles at home is the immense satisfaction you get from the process. There’s a real sense of pride and accomplishment when you create something beautiful with your own two hands. Making candles allows you to express your creativity and make each candle truly unique. You can customize your homemade candles with scents, colors, shapes, and designs that reflect your personal style and taste. The ability to personalize your candles makes them extra special. When you gift your homemade candles to friends and family, they are especially heartfelt because you infused a part of yourself into the creation process. Beyond the pleasure of personalization, the hands-on experience of making candles is intrinsically rewarding. Melting wax, choosing scents and colors, and shaping the wax into candles engages your senses and provides an almost meditative, relaxing activity. The satisfaction gained from crafting candles from start to finish with care and creativity is unmatched by any store-bought candle.

Conclusion

In summary, making candles at home can be a cost-effective hobby or side business depending on several factors. The main supplies like wax, wicks, and fragrance oils are very affordable, often costing just $1-5 per candle. This compares favorably to store-bought candles which can range from $5 for generic unscented tealights to $50 for premium scented pillar candles from luxury brands. However, factors like startup equipment, learning curve, labor time, quality of materials, personal preferences, and desired profit margin can affect the overall cost-effectiveness.

With practice and economical sources for materials, homemade candles can be produced for a fraction of the price of retail candles while providing the satisfaction of creating something with your own hands. But the initial investments in supplies and equipment should be considered when calculating costs and profits. Overall, candle making can be an enjoyable and inexpensive hobby, or a potential side business if costs are carefully controlled.