How Do I Make My Own Homemade Soap?

Making your own homemade soap has become an increasingly popular hobby and small business in recent years. According to market research, the global handmade soap industry generated around $7.5 billion in revenue in 2022, with an expected growth rate of 4.8% per year (https://www.linkedin.com/pulse/handmade-soap-market-expected-generate-revenue-usd-1041-singh). In the US, there are an estimated 300,000 soapmaking businesses, with 95% owned by women (https://blog.anthonythomas.com/todays-soapmakers-demographics-and-statistics). The appeal of homemade soap lies in its natural ingredients, cost savings compared to store-bought soap, and the ability to customize recipes. Handcrafting soap at home enables the use of nourishing oils like olive, coconut and shea, as well as essential oils, herbs, clays and other additives. Doing it yourself eliminates unnecessary chemicals, preservatives and artificial fragrances found in commercial soaps. And you can tailor homemade soap to your own skin type, scent preferences and desired qualities like moisturizing or exfoliating. This guide will walk through the entire soapmaking process from start to finish.

Ingredients Needed

The main ingredients needed to make homemade soap include oils/fats, lye, water, and essential oils or fragrance oils. Here are some common ingredients used:

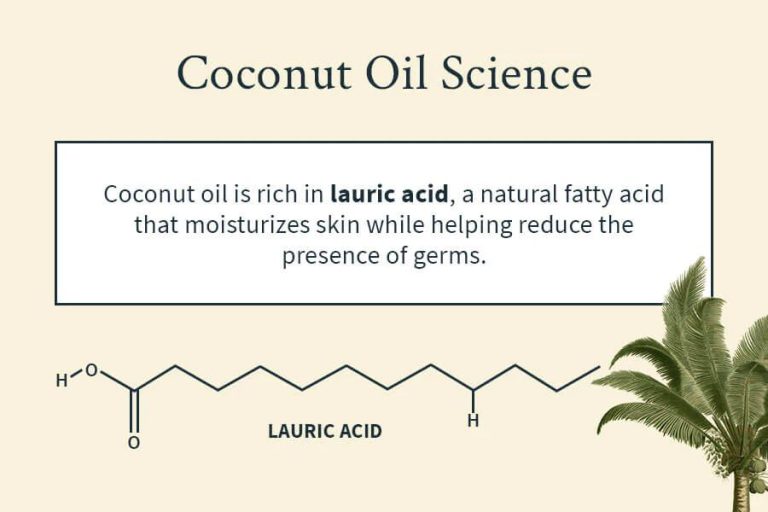

- Oils/Fats – The oils provide moisturizing properties and contribute to lather and hardness. Common oils used include olive oil, coconut oil, palm oil, canola oil, shea butter, and cocoa butter. Each oil has different properties.

- Lye – Also called sodium hydroxide. This provides the chemical reaction that causes saponification and turns the oils into soap. Lye must be handled carefully as it can cause burns. Always add lye to water, not the other way around.

- Water – Used to create the lye solution. Distilled water is recommended.

- Essential Oils – For scent. Use .5-1 ounce per pound of oils. Popular choices include lavender, peppermint, tea tree, and lemon.

- Colorants – Use 1 teaspoon per pound of oils. Options include mica powder, oxides, clays, etc.

- Molds – Commonly made of plastic, wood, or silicone. Allow the soap to set up before unmolding.

The specific ingredients and quantities will depend on the recipe. Most recipes use a combination of hard, cleansing oils like coconut oil along with moisturizing oils like olive and shea butter. Refer to soapmaking resources for recipe ideas and oil properties.https://www.thesprucecrafts.com/basic-soap-making-recipes-517179

Safety Precautions

When making homemade soap, it’s very important to take proper safety precautions when working with lye, which is a caustic chemical. Lye can cause severe burns if it comes into contact with skin or eyes, so it’s critical to wear protective equipment like gloves, goggles, long sleeves and pants while making soap.

The Soap Guild recommends wearing gloves and goggles anytime you handle lye, as lye burns can happen quickly if you splash or spill it on your skin or eyes. They advise having vinegar on hand to neutralize lye spills, and recommend calling emergency services if you ingest lye (Soap Guild).

Bramble Berry suggests making your soap in a well-ventilated area like outside or near an open window. Only use heat-safe containers made of stainless steel or plastic to mix your lye water, never glass which can shatter. Always add lye to water slowly and stir well before adding oils. Store lye in a safe, locked place away from children and pets (Bramble Berry).

The Soap Queen advises wearing long sleeves, pants, closed-toe shoes, gloves, and goggles whenever handling lye as it can quickly cause severe burns. She recommends having large amounts of water and vinegar nearby in case of spills. Children and pets should be kept away from your soaping space for their safety (Soap Queen).

Equipment Needed

When making homemade soap, it’s important to have the proper equipment. Here is some of the basic equipment you’ll need:

- Digital scale – Accurately weighing your ingredients is crucial for soapmaking. You’ll need a digital scale that measures in ounces or grams. Look for one with a capacity of at least 5 pounds.

- Thermometer – A thermometer allows you to monitor the temperature of your soap. You’ll want one that clips onto the side of your pot or beaker and measures up to at least 200°F.

- Stick blender – A stick blender makes it easy to blend the soap ingredients together. Look for one with a stainless steel blending shaft.

- Soap molds – You can pour your soap batter into silicone molds, wood molds, or even repurposed containers. Make sure they are heat resistant.

- Mixing bowls – Stainless steel or heat-resistant plastic bowls work well for mixing up your soap ingredients.

- Spoon – Use a stainless steel or heat-resistant plastic spoon for mixing.

You may also want to invest in eye protection, gloves, and an apron for safety when working with lye. Refer to The Nerdy Farmwife’s soapmaking equipment list for more details on the basic tools you’ll need.

Calculating the Recipe

One of the most important parts of making homemade soap is properly calculating the recipe. This involves determining the right amounts of oils, water, and lye needed to saponify into soap. Saponification is the chemical reaction between the lye and fats that creates soap.

To calculate your recipe, you’ll need to use a lye calculator. This allows you to input the types and amounts of oils to determine how much lye and water is required. Lye calculators account for the unique saponification values of each oil.

When choosing oils, it’s important to understand their properties. For example, oils like olive and coconut are cleansing while oils like shea butter are moisturizing. Using a blend creates a bar with balanced qualities. The percentages of hard, soft, and liquid oils impact the hardness, lather, and feel of the finished soap.

Follow your lye calculator’s instructions closely to safely measure ingredients. Accurately calculating your homemade soap recipe using a lye calculator helps ensure you end up with a successful bar of soap.

Melting and Mixing

After gathering your ingredients, the next step is melting the oils and mixing the lye-water solution. The Key here is to bring both mixtures to the proper temperature before combining them.

Melt the oils and butters in a pot or crockpot on low heat until everything is fully liquefied. Avoid overheating the oils. According to The Nerdy Farm Wife, oils should be melted to 100–110°F to prepare for mixing [1].

In a separate container, slowly stir the lye into the water (never the other way around). An exothermic reaction takes place that quickly heats the mixture. Allow the lye-water to cool to 100–110°F before combining with the oils. This ensures both mixtures are within the ideal temperature range for soap making [2].

Once both mixtures have reached the target temperature range, slowly pour the lye-water into the melted oils while stirring steadily. Use a spatula or stick blender to fully incorporate the two mixtures together.

Adding Scent and Color

You add scent and color after the soap has emulsified and when it has reached a “light trace” consistency. This step is usually done after you have mixed the lye-water and oils together and before pouring the soap mixture into molds. The light trace state allows the fragrance and colorants to incorporate evenly throughout the soap batter.

There are various options for scents and colors in homemade soap:

– Essential oils: You can use pure essential oils like lavender, lemon, or tea tree oil. Start with 0.5-1 ounce of essential oils per pound of soap – adding too much can cause the soap to seize. See https://onemotivatedmommy.com/soapmaking-for-beginners-fragrances-and-colour/

– Fragrance oils: These are blended fragrance oils made for soapmaking. Use around 0.7-1 ounce per pound of oils. Like essential oils, too much fragrance can cause seizing.

– Natural colorants: You can color soap with herbs, spices, clays, or micas. Infuse herbs in oil before soapmaking. For clays and micas, use 1 teaspoon of colorant per pound of soap. See https://www.brambleberry.com/how-to/soap/art0012-color-handmade-soap.html

– Liquid soap dyes: These are concentrated, non-bleeding dyes made for cold process soap. Use just a few drops per pound of soap.

– Food coloring: Basic food coloring can be used but may bleed or fade. Use sparingly in soap.

Pouring into Molds

Once your soap base has melted and you’ve added fragrance, colorants, and any additives, it’s time to pour the soap into molds. It’s best to pour at a light trace, which is when the soap starts to thicken slightly. This will help prevent air bubbles in your finished soap bars.

![]()

Select molds that are heat resistant and line them with silicone molds or freezer paper. Slowly and carefully pour the soap into the molds, starting in one corner and working your way across. Tap the molds lightly on the counter to release any air bubbles.

After pouring, let the molds sit undisturbed while the soap sets up. You can place the molds on a heating pad or wrap them in towels to help insulate and retain heat while the soap hardens. This will prevent cold spots and cracking. Allow the soap to set in the molds overnight before unmolding.

For more tips, check out this guide on how to pour melt and pour soap into molds.

Unmolding and Curing

After the soap has saponified and hardened in the mold for at least 24 hours, it is ready to be unmolded and cured. The ideal curing time for cold process soap is 4-6 weeks, though it can be used after 48 hours. According to Lovely Greens, the curing process allows the excess water to evaporate so the soap bars become milder, harder, and last longer (https://lovelygreens.com/how-to-cure-handmade-soap/). Curing allows the soap to become more firm and fully saponify. Rushing this process by unmolding and cutting too soon can result in soft spots, cracks, or dents in the finished bars.

To properly cure soap, first gently unmold each bar and cut into individual pieces. Arrange the bars in a single layer and allow air circulation around each one. Avoid excessive heat, humidity, or light during curing. Turn the bars every few days. After 4-6 weeks, the soap is fully cured and ready for use. Curing soap correctly results in a hard, mild, long-lasting bar.

Customizing Recipes

One of the best things about homemade soap is the ability to customize and experiment with different ingredients. Once you understand the basic soap making process, feel free to start substituting oils or adding specialty ingredients to create your own signature recipes.

Some common oil substitutions include:

- Replacing coconut oil with palm oil for a harder bar

- Using all olive oil for an ultra-moisturizing bar

- Subbing in avocado oil or sweet almond oil for a luxurious lather

You can also add a variety of ingredients to make your soap more nourishing or suited to your skin type:

- Add honey, oats, sea salt or coffee grounds for exfoliation

- Try milk, yogurt or cream for extra moisturizing properties

- Infuse with calendula, lavender or chamomile for soothing sensitive skin

- Mix in activated charcoal or clay for oily and acne-prone skin

When substituting or adding new ingredients, be sure to run your recipe through a lye calculator again to get the right balance of oils to lye solution. With some creativity and trial and error, you can develop signature soap recipes that reflect your own personal tastes and skin care needs.