Why Is My Soy Candle Curdling After Burning?

Candle making with soy wax is popular because it’s a clean-burning, renewable wax made from soybeans. However, soy wax can be tricky to work with. One common problem is curdling, where the top layer of wax develops a lumpy or grainy texture as the candle burns. This not only looks unappealing but can also impact the candle’s burn performance. In this article, we will provide an overview of why curdling happens in soy candles and discuss the main factors that contribute to this issue.

What Causes Soy Candle Curdling?

The primary causes of soy candle curdling have to do with the composition of soy wax and interaction with fragrance oils. Soy wax is composed of hydrogenated soybean oil. The chemical composition means it has a lower melting point than paraffin wax, making it prone to issues when combined with fragrance oils.

Many fragrance oils, especially those containing vanillin or essential oils like lavender or rose geranium, can cause curdling in soy wax. This happens because the fragrance oil is a lower temperature than the liquid wax. When the oil is added, it cools the wax around it rapidly, causing clumps and curdling in the wax (source).

To prevent curdling, it’s important to avoid overheating the wax, only using the recommended fragrance oil ratios for soy wax, and ensuring proper cooling and curing of the candles after pouring.

Wick Issues

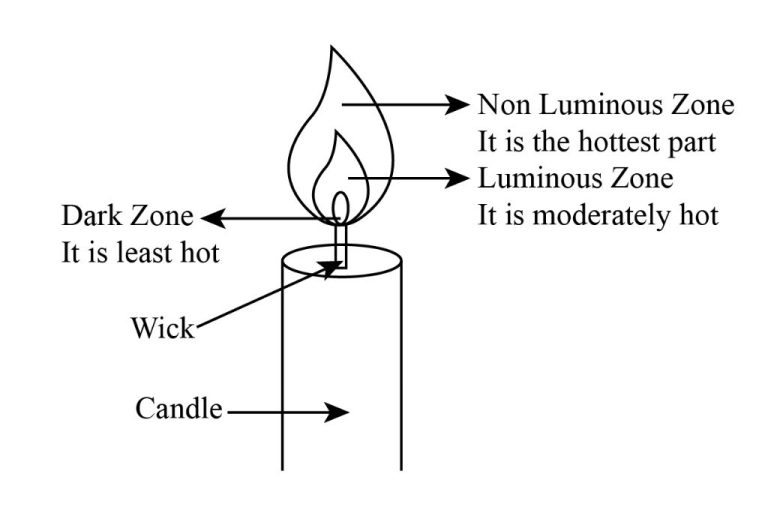

The wick is one of the most common causes of soy candle curdling. If the wick is too small, it won’t be able to draw up enough wax which can lead to poor melt pools and cooling issues. On the other hand, if the wick is too large, it will burn too hot in the center and cause the wax to break down and curdle (Candlescience.com). The proper wick size for soy candles depends on the diameter of the container but finding the right balance is crucial.

Additionally, soy candles require a full cure time before burning. Burning too soon can lead to curdling even with the right wick size. Most soy wax blends need a minimum of 24 hours to cure but 48-72 hours is recommended for best results. This allows the crystals to fully solidify and prevents issues like frosting, curdling, and poor melt pools (Reddit.com/r/candlemaking).

Additives

Certain additives like Vybar 260 can help prevent soy candle curdling. Vybar is a proprietary additive made by Candlewic that helps enhance fragrance retention, improve color quality, increase hardness and gloss, and reduce mottling in soy candles (https://lonestarcandlesupply.com/vybar-260). It has a lower melt point than soy wax and is commonly added at 1-3% by weight.

According to Candle Making Supplies, Vybar 260 works by binding to the soy wax on a molecular level which helps reduce wax crystals from forming (https://www.candlemakingsupplies.net/shop/wax-and-additives/vybar-260-candle-additive). These crystals can make the wax appear curdled and grainy. The right amount of Vybar helps provide a smooth appearance. Too much Vybar though can start to make the wax cloudy.

Other additives like Vybar 103 can also help, but Vybar 260 seems optimal for preventing soy wax curdling specifically. As with any additive, carefully test the percentage used during candle testing to find the ideal amount for your particular wax and fragrance oil combination.

Fragrance Oil

The amount of fragrance oil used in soy candles can impact curdling. Most experts recommend a fragrance load between 5-10% of the wax weight (Candle Creations). Exceeding 10% fragrance load increases the risk of curdling, especially with temperamental fragrances.

Fragrances like vanilla and florals (e.g. lavender, geranium) are known to cause curdling in soy wax more often. The flashpoint of the fragrance oil is also a factor – fragrances with lower flashpoints tend to create more issues (All Seasons Wax Company). Using a fragrance with a higher flashpoint above 170°F can help prevent curdling.

Testing fragrances at lower percentages first is recommended to determine the optimal fragrance load for that particular oil and wax blend. Keeping within the 5-10% guideline fragrance load range is the best prevention against curdling from too much fragrance.

Pour Temperature

Proper pour temperature is crucial when making soy candles to avoid curdling. Soy wax needs to be poured between 135-145°F to ensure proper adhesion and cooling. If poured below 135°F, the wax can start to solidify too quickly before having time to adhere to the container. This leads to separation and that curdled appearance on top.

According to Candle-Shack.com, “This happens because the fragrance oil is at a lower temperature than the liquid wax. When the oil is added to the wax it cools the wax and causes it to start to harden.”

CandleCreation.co.nz also states, “This usually occurs when the pour temperature is too low. If the candles are cooling too quickly the wax on top dries while the underneath is still quite warm.”

To avoid curdling due to temperature, make sure to heat the wax to 145°F before pouring to account for cooling. Use an infrared thermometer to accurately measure the wax temperature right before pouring into containers.

Curing

Proper curing is crucial for preventing soy candle curdling. After pouring soy candles, allow them to cure for 24-48 hours before lighting to allow the wax to fully set up and solidify. During the curing process, soy wax crystallizes and contracts slightly, which helps prevent issues like frosting, separation, and curdling on the candle surface when burned. Most candle makers recommend curing soy candles for at least 24 hours, while 48 hours is ideal for maximum stability. The curing timeframe depends on factors like wax type, fragrance load, and ambient temperature. Curing soy candles in a cool, dry area away from direct light will help facilitate proper crystallization.

According to candlemaking.com, curing is so important because soy wax continues to crystalize long after candles are poured and cooled. If candles are burned too soon, the flame can cause uneven crystallization, leading to a lumpy appearance.[1]

[1] https://www.candlescience.com/learning/how-to-prevent-soy-candle-splotches/

Wax Quality

One of the main causes of soy candle curdling is using lower quality wax. Food grade soy wax is meant for products like crayons and has more oils and impurities that can rise to the surface when burned, creating a curdled look. Candle grade soy wax is highly refined and specially formulated for candle making with a higher melting point to prevent curdling. According to CandleCreations.co.nz, “Food grade wax contains more impurities as it’s not as highly refined. These impurities move to the surface of the candle as it’s burning and it makes the wax appear to curdle.”

To prevent curdling, it’s recommended to use soy wax marketed specifically for candle making, like GB 464 or CD container wax. The purification process removes more oils and acids that could rise during burning. While food grade wax is cheaper, the lower quality can result in curdling and a poor burn. Investing in the proper candle grade wax leads to a smoother appearance and cleaner burn.

Container Issues

The type of container used for soy candles can impact curdling. Containers made from certain materials like tin and aluminum can transfer heat too quickly, resulting in uneven cooling and crystallization on top of the candle. Glass and heat-resistant plastic like polypropylene are better materials that allow for slower, more even cooling.

The design of the container also matters. Containers with a wide mouth vs. a narrow mouth will impact how the heat dissipates as the candle cools. Heat tends to escape more quickly from wide mouth containers. A best practice is to use a container with a narrow opening for soy wax candles to promote slow, even cooling from top to bottom which reduces curdling.

Additionally, containers should be room temperature before pouring soy wax into them. Pouring hot wax into a cold container causes rapid uneven cooling and increases risk of curdling on top. Allowing container to reach room temperature first avoids this problem.

Source: https://candle-shack.com/blogs/all-blogs/what-is-the-curdling-effect-and-why-does-it-happen

Conclusion

Soy candles can look unappealing if they start to develop a curdled or frosting appearance while burning. However, in most cases the problem can be fixed with some simple troubleshooting. The main causes tend to be issues with the wick being too small or clogged, problematic additives or fragrance oils, pouring the wax at the wrong temperature, insufficient curing, or low quality wax. Adjusting the wick size, testing different fragrance oils and additives, carefully controlling pour temperatures, allowing for proper cure time, and using high grade soy wax should prevent curdling. With some tweaking of the variables, soy candle makers can perfect their formulas and end up with beautifully burning candles. Just remember to be patient and systematically test each element.