Where Do We Get Wax?

Wax is defined as a substance that is typically solid, but becomes liquid at higher temperatures, and consists mostly of hydrocarbon molecules (“Wax Definition & Meaning”). It is produced in nature, primarily by bees and plants, but can also be made synthetically. Waxes have a wide variety of uses and properties that allow them to serve purposes like waterproofing, shine, and protection. The major natural sources for wax come from bees, plants like carnauba and candelilla, and animals such as sheep.

This article provides an overview of the major types of waxes, both natural and synthetic, highlighting where they come from and their common uses. We will explore beeswax, paraffin, carnauba, candelilla, soy, lanolin, montan, shellac, and synthetic waxes.

Beeswax

Beeswax is a natural wax produced by honey bees. Worker bees secrete beeswax from glands on their abdomens and use it to form the walls of the honeycomb where they store honey and pollen. Beeswax production begins when worker bees are 12-18 days old. To produce wax, bees consume honey which provides the energy needed for the wax-producing glands. The wax comes out as small flakes from the wax mirror on the underside of the bee’s abdomen. These flakes are then chewed and molded by the bee to become part of the honeycomb structure.

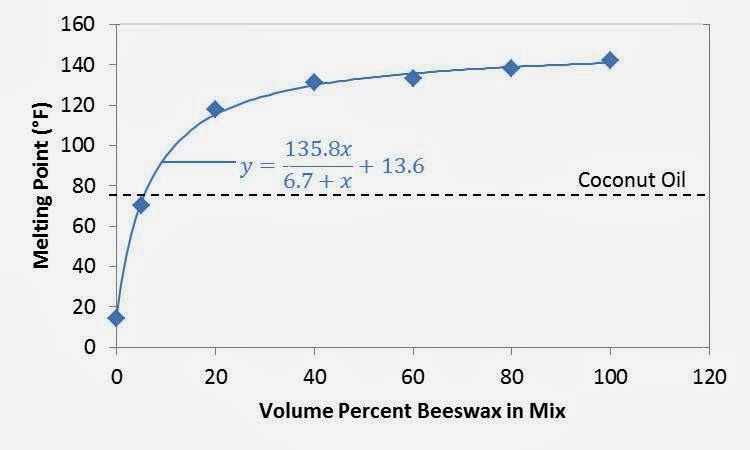

Beeswax has a high melting point range of 62 to 64 °C and is malleable when warm. It is insoluble in water but soluble in ether and chloroform. Some key properties of beeswax include:

- Has a sweet, honey-like scent

- Hydrophobic, repels water

- Malleable – can be shaped and molded

- Emollient, softens skin

Due to its unique properties, beeswax has a variety of uses. It is commonly used in candle making, cosmetics, polishes, and food. Beeswax is also utilized by bees in honeycomb foundations. These thin wax sheets are embossed with the hexagonal pattern of honeycomb and given to bees to build upon.

Overall, beeswax is an extremely useful and versatile natural wax produced by honey bees. The wax is harvested from the honeycomb when it is extracted for honey collection.

Paraffin Wax

Paraffin wax is a soft and colorless wax derived from petroleum. It is created when crude oil is distilled into lighter groups and then further processed to remove oils, resulting in a blend of long chain hydrocarbons called paraffin wax. Paraffin wax is solid at room temperature and begins to melt around 130–150 °F (54–66 °C). It is odorless and tasteless.

To produce paraffin wax, the raw petroleum is first distilled into gasoline, naphtha, kerosene and gas oil. The residue left over contains substances like asphalt and paraffin wax. The paraffin wax is then extracted using solvents and cooling techniques to form wax crystals that can be separated from the solution. The crystals are then refined further through sweating, pressing and filtering to remove impurities. This results in a purified, refined paraffin wax.

Paraffin wax has a wide range of uses, primarily due to its chemical properties. It is water-resistant, softening at body temperature yet solid at room temperature. This makes it useful for cosmetics, candles, art materials like crayons, and lubricants. It can also coat food containers and paper board. However, there are concerns that paraffin wax may release harmful chemicals when burned.

According to the Ehow article “Facts on Paraffin Wax”, paraffin wax starts off as crude oil that is boiled to become purified. The Jungleculture article “Are candles eco-friendly?” states that paraffin wax comes from the byproduct of gas distilleries and raises concerns over synthetic fragrances. The Puresoapsandcandles article “How to use an all-natural lotion candle” also mentions that paraffin wax originates from gas distilleries.

Carnauba Wax

Carnauba wax comes from the leaves of the Copernicia prunifera palm, a plant native to northeastern Brazil. It is harvested from the leaves by drying, beating and sifting them (https://www.newdirectionsaromatics.com/blog/products/all-about-carnauba-wax.html). Carnauba wax is one of the hardest natural waxes, with a melting point around 82-86°C. It contains fatty acid esters, free fatty alcohols, acids and hydrocarbons. Carnauba wax has many properties that make it useful including its hardness, high melting point, glossiness and hypoallergenic nature.

Some of the main uses of carnauba wax are (https://www.pikespeakautodetail.com/benefits-of-carnauba-wax):

- In car waxes, polishes and coatings to produce a glossy, water-repellant finish

- In cosmetics to provide texture, emulsify and thicken products

- To make candies and chocolates shiny and help them set up

- To coat fruits like apples and pears to extend shelf life

- In dental floss to make it more slippery and waxy

Candelilla Wax

Candelilla wax comes from the Candelilla plant (Euphorbia antisyphilitica), a small desert shrub native to northern Mexico and the southwestern United States. The Candelilla plant produces a protective wax coating on its stems and leaves to prevent water loss in the arid climate. The wax is extracted by placing the plants in boiling water or sulfuric acid to separate the wax from the plant matter (Extraction Methods and Common Uses of Candelilla Wax | 18, https://www.taylorfrancis.com/chapters/edit/10.1201/9781315232966-18/extraction-methods-common-uses-candelilla-wax-miguel-de-le%C3%A3n-zapata-cristobal-aguilar).

Traditional extraction methods are hazardous for workers and the environment. More eco-friendly extraction using solvents has been developed to make the process safer (Multiceras Develops Safer, Eco-friendly Candelilla Wax Extraction Process, Replacing a 105-Year-Old Tradition, https://www.prweb.com/releases/multiceras_develops_safer_eco_friendly_candelilla_wax_extraction_process_replacing_a_105_year_old_tradition/prweb11233487.htm).

Candelilla wax is hard, brittle, and highly-refined. It has a high melting point and low viscosity, making it a popular wax for candles, polishes, and cosmetics. It can also be used as a substitute for carnauba wax and beeswax (Multiceras on LinkedIn: #reliablesolutions #growconcept, https://www.linkedin.com/posts/multiceras_reliablesolutions-growconcept-activity-7103442965380902913-M-16?trk=public_profile_like_view).

Soy Wax

Soy wax is made from hydrogenated soybean oil. It is produced by extracting oil from soybeans and then hydrogenating it to convert the unsaturated oils into saturated waxes. Soy wax became popular in the 1990s as a renewable and environmentally friendly alternative to paraffin wax, which is a petroleum product. Compared to beeswax, soy wax has a lower melting point and tends to be softer, allowing for easy release from molds. Soy wax also burns more slowly than paraffin or beeswax.1

The main uses of soy wax are in candles, lotions, lip balms, and soap. It blends well with essential oils and fragrances. The clean-burning properties of soy wax make it ideal for candles. It produces less soot than paraffin wax candles. Some people prefer soy over beeswax for candles because it is typically less expensive. However, others prefer the sweet, honey-like scent of beeswax. Soy wax and beeswax candles have different texture, scent, and burning properties that impact the final product.

Lanolin

Lanolin is a wax secreted by sheep’s wool glands. It forms a protective coating on sheep’s wool and skin. The main commercial source of lanolin is raw sheep’s wool (https://www.glpbio.com/lanolin.html).

Lanolin is extracted from sheep’s wool using a mechanical and chemical process. The wool goes through several washings with detergent to remove dirt and impurities. The lanolin is then extracted by centrifugation or solvent extraction. The crude lanolin is further purified to remove impurities (https://pubmed.ncbi.nlm.nih.gov/35481824/).

Lanolin has many applications due to its emollient properties. It is commonly used in skincare and cosmetics as a moisturizer, and in pharmaceuticals as an emulsifier and coating agent. Lanolin is also used to lubricate machine parts and in shoe polish. In the food industry, it can act as a surface coating to prevent stickiness.

Montan Wax

Montan wax is extracted from lignite, a type of coal, using a solvent extraction process (https://www.parchem.com/chemical-supplier-distributor/montan-wax-052829). It has a high molecular weight and consists of a complex mixture of hydrocarbons. Unlike other waxes, montan wax contains very little free wax acids or esters.

Montan wax has several useful properties. It is hard, has a high melting point of 82-95°C, and is resistant to acids, alkalis and solvents. It also provides gloss and enhances slip. Due to its properties, montan wax is widely used in polishes and coatings. It helps make surfaces water-resistant while improving abrasion resistance. Other uses are in lubricants, printing inks, and carbon paper.

Shellac Wax

Shellac wax is derived from the secretions of the female lac insect (Laccifer lacca). These insects thrive on trees in the forests of India and Thailand, secreting the resinous shellac substance to form cocoons for their larvae. The sticks containing the cocoons are harvested and processed to extract the raw shellac, which contains about 50-70% resin, 25% wax, and the rest coloring matter and debris.1

To produce shellac wax, the raw shellac goes through a sequence of purification steps to remove the colored resin and debris. It involves filtration, washing, and centrifugation, ultimately yielding a refined yellow waxy product. Shellac wax is characterized by its high melting point and low tackiness.

The non-polar structure of shellac wax makes it useful for a variety of applications. It is commonly used in cosmetics and pharmaceutical preparations as a thickening agent, emulsifier, and coating material. Shellac wax helps modify the feel, release, and texture profile of cosmetic products like lipsticks, eye makeup, and creams. It also finds use in the metal, leather, tobacco, and paper industries due to its film-forming and waterproofing properties.2

Conclusion

In summary, some of the major sources of natural and synthetic waxes are beeswax produced in the beehives of honey bees; paraffin wax made from the distillation of petroleum; carnauba wax harvested from the leaves of the carnauba palm tree; candelilla wax from the candelilla shrub; soy wax made from hydrogenated soybean oil; lanolin extracted from sheep’s wool; montan wax derived from lignite coal; and shellac wax secreted by the lac insect. Both natural and synthetic waxes have a wide variety of uses and properties that make them an integral component in many products and industrial processes.