What Type Of Candle Wick Is Best?

There are several types of candle wicks available, each with their own pros and cons. The main options include cotton, wooden, zinc core, paper, beeswax, and lead core wicks. Choosing the right wick is important for getting the best burn performance. Factors like flame size, melting rate, soot production, and drowning need to be considered when selecting a wick.

The most common and versatile option is cotton wicks. Wooden wicks make a crackling sound and are best for soy candles. Zinc core wicks provide a strong and rigid structure, while paper wicks work well for beeswax candles. Beeswax wicks are good for natural, beeswax candles. Lead core wicks allow large pillar candles to burn cleanly but do carry some health warnings.

Proper wick sizing is also critical, as a wick that is too small or too large can lead to issues like tunneling. This article will provide an overview of the different types of wicks, their key properties, and recommendations for optimal performance.

Cotton

Cotton is one of the most common wick materials used in candle making. Cotton wicks are made from natural cotton fibers that are braided or twisted together to form the wick (The Ultimate Candle-Making Guide: How to Create Scented …). The pros of cotton wicks include their wide availability and affordability. Cotton can be purchased easily online or at local craft stores. The natural fibers also provide a cleaner, safer burn compared to some synthetic wick materials. However, cotton does have some downsides. The natural fibers can create more soot than core or paper wicks, leading to more frequent trimming of the wick. Cotton also lacks the rigidity of other materials, which can lead to issues like curling or bending of the wick (Rayon Wick). Overall, cotton makes a good choice for beginner candle makers thanks to its natural composition and easy accessibility.

Wooden

Wooden wicks are usually made from wood veneers wrapped around a cotton core (Source). The wood veneer allows the wick to crackle as it burns, creating a pleasant popping sound. Some key benefits of wooden wicks include:

- They burn cleaner than regular cotton wicks, producing less soot

- The crackling sound can be soothing and relaxing

- Wooden wicks are made from a renewable resource (wood)

- They tend to burn cooler than cotton, which helps preserve fragrance

- Wooden wicks reduce “mushrooming” or chars forming on the wick tip

Potential downsides are that wooden wicks may be more expensive than regular cotton and some find the crackling sound bothersome. They also require properly-sized candle jars to avoid wick damage. Overall, wooden wicks are a unique option that creates a pleasing sensory experience while burning cleaner than plain cotton (Source).

Zinc Core

Zinc core wicks consist of a cotton wick braid with an inner zinc core inserted for stability and rigidity. The zinc helps the wick stand upright and remain centered in the wax pool as the candle burns [1]. This provides an even, consistent flame with less mushrooming or smoking compared to a regular cotton wick.

The zinc core is sturdy enough to support larger candle wicks that might otherwise bend and drown in the melted wax. It allows zinc core wicks to be used in containers, pillars, votives and other candle styles [2]. The inner zinc strand burns away slowly during combustion without releasing any toxic fumes.

Zinc core wicks are often numbered with two measurements, such as 44-24-18 or 51-32-18. The first number refers to the overall wick diameter, the middle number is the inner zinc core diameter, and the last number indicates the fiber braid twist [1]. A range of zinc core wick sizes allows candle makers to pair the proper wick with the wax type, wax pool diameter and other factors for optimal performance.

Paper

Paper wicks are made of flat braided paper that is coated in wax. The main benefit of paper wicks is that they produce less soot and smoke than cotton wicks (The Different Types of Candle Wicks). Since they are flat, paper wicks allow for larger melt pools compared to round cotton wicks. This provides more fragrance throw. Paper wicks tend to provide a cleaner, more even burn. However, they may not be as sturdy as cotton wicks and can only be used with certain wax types. Paper wicks need to be kept upright to avoid issues like tunneling. Overall, paper wicks are a good option if you want to minimize soot and maximize fragrance dispersal, but they require more care when wicking the candle.

Beeswax

Beeswax candle wicks are made from natural beeswax. The advantages of beeswax candle wicks include:

Beeswax has a natural sweet honey scent that some find pleasant. The natural aroma comes through when burning a candle with a beeswax wick (https://www.greenerlyfe.com/blog/pros-and-cons-of-beeswax-candles-we-review-the-facts/).

Beeswax wicks are coated to help the candle burn cleaner and prevent soot. The coating, often made of wood rosin, helps strengthen the wick as well (https://www.thefarmerscupboard.com/blogs/bees-honey/pros-and-cons-of-beeswax-candles).

However, beeswax can be more expensive than other wick materials. It also has a lower melting point than synthetic wicks, making large candles with beeswax wicks harder to maintain (https://www.thefarmerscupboard.com/blogs/bees-honey/pros-and-cons-of-beeswax-candles).

Lead Core

Some candle manufacturers used to make cotton wicks with a lead core to help the wick stand upright and burn brighter. However, this practice has been highly controversial and ultimately banned due to health risks. As the candle burns, trace amounts of lead can enter the air and be inhaled by those nearby (1).

In the 1970s, a voluntary industry agreement was made to stop using lead in wicks, but testing in the 1990s still found some candles on the market with lead wicks (2). As a result, the U.S. Consumer Product Safety Commission officially banned lead-cored wicks in 2003 (3). Today, reputable and ethical candle makers avoid lead in their wicks entirely.

Sources:

(1) CPSC Bans Candles With Lead-Cored Wicks

(2) No more candles with lead cores: U.S. agency

Wick Sizing

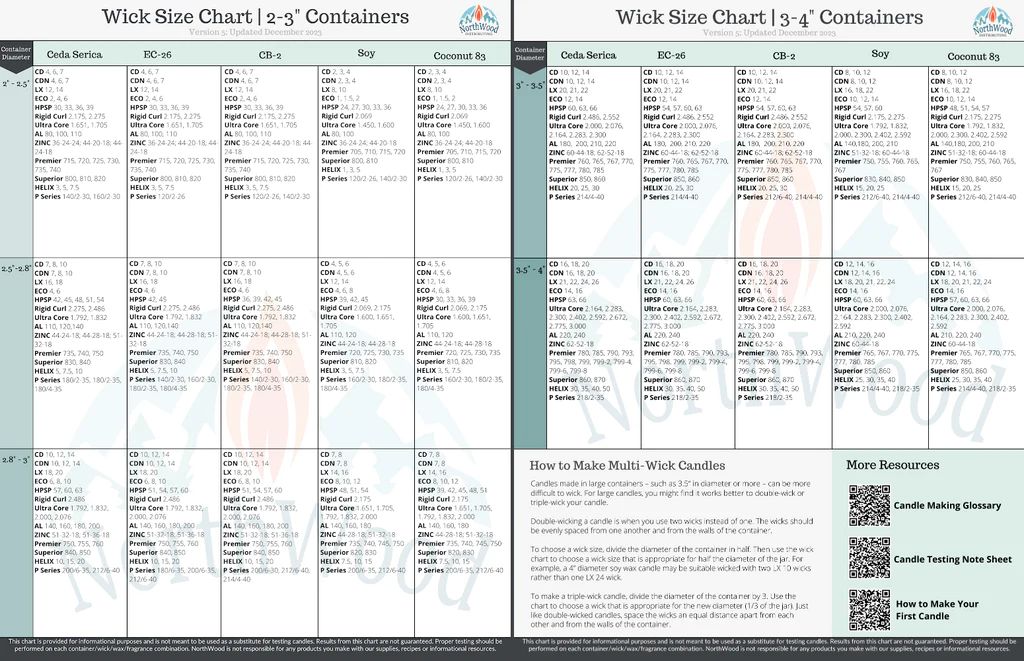

One of the most important factors in choosing the right candle wick is matching the wick size to the diameter of the candle. The general rule is that the wick size should be proportional to the diameter of the candle – a larger candle needs a larger wick, while a smaller candle needs a smaller wick. This helps ensure proper melting and an even burn.

As a guideline, a good starting point is to choose a wick that is 1/6th to 1/4th the diameter of the candle. For example, for a 2″ diameter candle, a wick between 1/3″ and 1/2″ would be appropriate. There are more precise wick sizing charts available that recommend specific wick sizes based on wax type and candle diameter. For example, this wick sizing chart from CandleScience provides recommendations for different wax types.

Testing different wick sizes with the particular wax, fragrance, and vessel is recommended to find the best burn for each candle. The wick should burn down about 1″ per hour and reach the edges without leaving unburned wax around the sides.

Wick Tab

A metal wick sustainer tab is an important component for safe candle making. The purpose of the wick tab is to anchor the wick and prevent it from falling into the melted wax pool as the candle burns. According to The Humble Wick Tab, metal tabs “play a really important role in the safety of your candles.” Without a tab, the wick may burn too low and ignite the candle vessel.

Proper wick tab sizing depends on the wax, wick and vessel type. For container candles, a good rule of thumb is to size the tab about 1/8″ below the top of the vessel. The tab should be flush with the bottom for votives and tea lights. When making candles without tabs, extra care must be taken to test wick length and trim wicks as needed. While possible to make candles without tabs, most candle makers recommend using metal sustainer tabs for safety.

Conclusion

The main factors to consider when choosing the best candle wick are the wax type, candle container size, and desired flame characteristics. Cotton core wicks work well for most wax types. Wooden wicks produce a crackling sound and larger flame. Zinc and paper cored wicks offer performance benefits but may emit more soot. For container candles, pairing the proper wick width to the diameter is key. Tabbed wicks help center wicks in wide containers. Testing wick types with your specific wax and jar is ideal to find the best option. Overall, cotton cored wicks provide a reliable starting point, while variables like wax, fragrance, and containers determine the ideal wick for each candle.