What Natural Dye Is Brown?

Natural dyes are colorants derived from plants, insects, minerals, or other natural sources. They have been used throughout history across cultures for textile dyeing and coloring. In recent years, natural dyes have seen a resurgence in popularity due to their sustainable and non-toxic properties compared to synthetic dyes.

Brown is an earthy, neutral color that comes in many shades and hues. It’s a popular color for textiles, leather, wood, food, and more. There are a number of natural sources that produce brown dyes, many coming from common trees, nuts, and plants.

History of Natural Brown Dyes

Natural dyes have been used throughout history to add color to textiles and other materials. The earliest evidence of natural dyeing dates back to 2600 BC in China 1. In ancient Egypt, colored pigments were found in the tomb of King Tutankhamun dating back to 1325 BC 1.

Early civilizations used plants, insects, and minerals to create dyes in colors like red, blue, yellow, green, brown, and black. Brown shades were commonly derived from walnut shells, oak bark, acorn shells, and certain roots or woods.

Oak bark produces a brown coloring due to the high levels of tannins. It has been used since ancient times in Europe to dye wool and cotton a brown or tan shade 2. The extract from black walnut shells also yields a brown dye, especially for wool. Walnut shells contain juglone, which reacts with air and fibers to create a lasting brown hue.

Other brown dyes came from the catechu plant found in Asia, which produces a brownish-gray dye called cutch. The extract from nuts of the acacia tree was also a common source of brown dye used in ancient India 2. These natural brown dyes were relied upon for centuries until the development of synthetic dyes in the mid-19th century.

Walnut Shells

Walnut shells can be used to produce a light to dark brown natural dye. Green walnuts contain the dye compound juglone which imparts a brownish color. Walnut shells are typically collected in June or July when the nuts are still soft and green. The shells are then dried in a cool, dark location until they become brittle.1

To make the dye, the dried shells are boiled in water for 30-60 minutes until the liquid becomes a rich brown color. Additional boiling concentrates the dye bath to achieve a darker color. The wool, yarn, or fabric to be dyed can then be immersed in the dye bath for 30-90 minutes at 180°F. Walnut shell dye works well on wool, silk, cotton, and other natural fibers and produces hues from tan to deep chocolate brown depending on the dye bath strength and mordant used.2 The color is lightfast and holds up well to washing. Overall, walnut shell dye provides a versatile natural brown dye option.

Oak Bark

Oak bark contains high amounts of tannins, which are plant-based chemicals that produce brown and tan colors when used for dyeing. Tannins bind to fibers like wool, silk, and cotton, forming a long-lasting bond that resists fading and washing out.1 The tannins interact with the fibers to produce soft brown and tan shades that can range from light beige to deep chocolate brown depending on the mordant used and dyeing technique.

Tannins have a natural affinity for protein-based fibers like wool and silk. They form strong ionic bonds with the amino acids in these fibers, creating a permanent color that is an integral part of the fiber rather than just a surface coating. This makes oak bark an ideal natural dye for woolens, tapestries, rugs, and other textiles made from animal fibers.

The bark is harvested from the branches and trunks of oak trees like white oak and black oak. It can be used fresh after harvesting or dried for later use. Simmering the bark in water releases the tannins and creates a dye bath that can be stored and used multiple times. Oak bark produces soft, versatile browns that have been used for centuries as a traditional textile dye.

Catechu

Catechu is a natural brown dye that comes from the heartwood of the catechu shrub. It has been used for centuries in India and Southeast Asia to dye fabrics, leather, and other materials a reddish-brown hue.CATECHU DYE The shrub’s harvested wood and bark are boiled to extract the catechu tannins, which produce the dye pigment. Catechu has a distinctive earthy scent similar to strong black tea. It results in a range of brown, beige, and sepia tones on natural fibers like cotton, linen, silk, and wool.

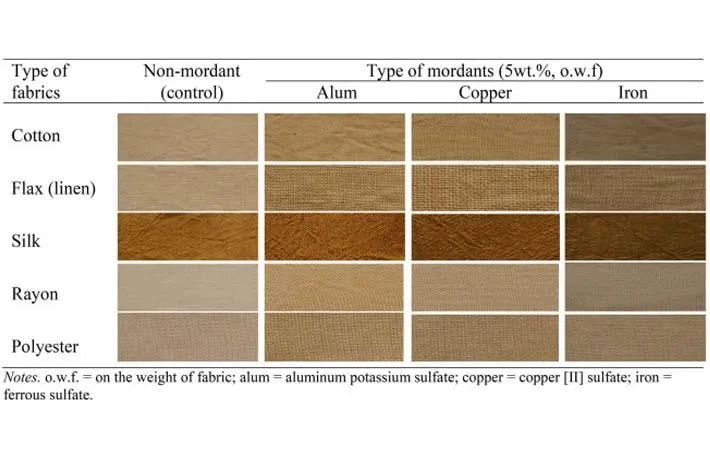

When used alone on protein-based fibers like wool or silk, catechu produces colors ranging from golden-brown to deep chocolate. On plant-based fibers like cotton and linen, it makes more muted beige and mossy green-brown hues. Varying the dye bath concentration and using mordants like iron or copper sulfate darkens the shades. Catechu works well for both immersion and bundle dyeing techniques. It can also be used in combination with other dyes to produce an array of complex, multi-toned effects on textiles.

Tea

Black tea can be used as a natural dye to give fabric a light brown color. The tannins in black tea bind to the fibers in the fabric and create a stain that is fairly colorfast and lightfast. According to Create Whimsy, tea has been used for centuries as a natural dye for fabrics. To dye fabric with black tea:

- Brew a strong pot of black tea and let it cool completely.

- Soak the fabric in the tea, making sure it’s completely submerged. Let it soak for at least an hour.

- Remove the fabric and air dry. The color may continue to develop as the fabric dries.

For best results, use cotton, linen or other plant-based fabrics. The natural tannins in the tea will bind best to these types of fibers. The longer you soak the fabric, the darker the brown color will be. Tea dyed fabric has an aged, vintage look popular for crafts and home decor projects.

Coffee

Coffee is a popular natural dye source for achieving brown shades. The tannins and caffeine in coffee act as a mordant and dye on fabric or yarn. To dye with coffee, first brew a strong pot of coffee using about 1 cup of ground coffee per 3-4 cups of water. Allow the coffee to cool slightly so it won’t damage or felt delicate fabrics like wool or silk. Pour the coffee over pre-wet fabric or yarn in a dye bath, making sure the item is fully submerged. Stir well and allow it to soak for at least an hour for pale shades up to overnight for darker browns. Rinsing and drying will “set” the color. The longer the item soaks, the darker the brown

One tip when dyeing with coffee is to save the coffee grounds after brewing and add them to the dye bath as well. The grounds will help bind the dye to the fabric. Their addition can make the shades richer and darker. To make the brown color fast, use an acid like vinegar or lemon juice as a mordant in the dye bath. About 1/4 cup per gallon of water is sufficient. The acid helps the dye bond permanently to the fibers. With mordanting, the coffee dye will not bleed or fade with washing. For best results, use natural plant fibers like cotton, linen or cellulose fibers which readily absorb dye compared to synthetics.

Compared to other natural dyes, coffee produces a range of brown shades from light tan to deep espresso. The hue can vary based on the brewing method, roast of the beans, and dyeing time. Lighter roasts and cold brew coffee tend to yield paler browns. With longer dyeing times, the shade becomes progressively richer and darker. Used alone or in combination with other natural dyes, coffee is an excellent choice to sustainably color fabric and yarn brown.

Tobacco

Tobacco leaves contain a natural brown pigment that can be extracted to dye fabrics and yarns (Dharma Acid Dyes for Silk, Wool, and Nylon). When tobacco leaves are boiled in water, the brown pigments leach out into the water, creating a rich, warm brown dye bath. The main brown pigments in tobacco leaves are nicotine and other alkaloids, which bind well to protein fibers like wool and silk.

To make a natural brown dye from tobacco, the leaves are first boiled to extract the pigments. The extracted liquid is then strained and used as a dye bath. Protein fibers like wool and silk are then submerged in the liquid to absorb the brown color

. Tobacco leaf dye results in a range of golden browns, from toffee to chocolate brown depending on the mordant used and dye technique. It’s an eco-friendly way to naturally dye yarn and fabrics a beautiful warm brown tone (Tobacco Leaves Hand Dyed Wool).

Other Sources

There are many other plants, vegetables, and organic materials that can produce natural brown dyes, though some may be less common or provide less vibrant shades compared to options like walnut shells and oak bark. Some examples include:

Acorns: These contain high levels of tannins that help bind to fibers and produce browns and tans. The Art and Craft of Natural Dyeing notes oak galls created by insects on oak trees can also be used.

Mushrooms: Certain mushrooms like P. sapidus or the Shaggy Mane can produce shades from light tan to dark chocolate brown.

Onion skins: Soaking onion skins in water creates a golden brown dye bath ideal for wool and other animal fibers.

Clover: Fermenting clover leaves and flowers also generates brownish dyes.

Other common natural dye sources for brown hues are chestnuts, pine cones, banana peels, avocado pits/skins, and rhubarb leaves, though exact shades can vary.

Conclusion

When it comes to natural brown dyes, some of the most popular and commonly used sources today include oak bark, walnut shells, and tea. These natural dyes have been used for centuries to color fabric and clothing across many cultures. The benefits of using natural dyes over synthetic ones include their sustainability, low environmental impact, and hypoallergenic properties for those with sensitive skin.

Oak bark produces a light tan or brown hue when used for dyeing. It has tannins that act as a natural mordant to help the dye bond well to fibers like wool and cotton. Walnut shells create a deep, rich brown and also contain their own mordant. The brown dye derived from black tea is easy to produce and has an earthy tone. While synthetic dyes offer color consistency and vibrancy, natural dyes connect us to traditions and sustainable practices of the past. As more consumers seek eco-friendly products, natural brown dyes continue to grow in popularity and use.