What Does Ht And Ct Mean In Candle Making?

HT stands for “High Temperature” and refers to the temperature of the melted wax pool during burning. High temperature waxes like paraffin generally have a melted pool temperature between 150-170°F.

CT stands for “Cold Throw” and refers to the strength of scent from an unburned candle. Waxes with good cold throw allow fragrance oils to release scent into a room even when not lit. Cold throw is especially important for large pillars and jars.

Understanding how HT and CT work together is key for choosing the right waxes and customizing your candle’s performance. HT impacts how high the wax pool reaches during burning, which affects melt pool depth, burn time, and wax consumption. CT determines how strongly fragrance is released when the candle is unlit. Finding the right balance of HT and CT helps maximize both hot scent throw and cold scent throw.

HT – High Temperature

HT stands for “High Temperature” and refers to the temperature of the melted wax pool when the candle is burning. The HT indicates how hot the wax and wick get once the candle is lit.

In candle making, HT typically ranges from 150°F to 185°F (65°C to 85°C). The goal is to achieve an HT within this range for optimal performance. If the HT is too low, the wax will not melt properly and the candle may tunnel or have poor wax pool formation. If the HT is too high, it can create excessive sooting from the wick.

Striking the right HT offers several benefits for candles:

- Proper wax pool formation and full melt

- Reduced risk of tunneling

- Minimized sooting

- Consistent burn and fragrance throw

- Maximized burn time

Testing candles to determine HT is an important part of the candle making process, and allows the creator to dial in the perfect HT for their needs. This results in high-performance, long-lasting candles that burn cleanly from edge to edge.

CT – Cold Throw

Cold throw refers to how well a candle’s fragrance can be smelled when the candle is not lit. A candle with good cold throw will have a noticeable fragrance even when unburned. The intensity of a candle’s cold throw depends on the fragrance oil used, the wax, and the candle vessel.

Fragrances with higher concentrations of top notes tend to have better cold throw. Top notes are the first scents released when a fragrance oil is exposed to air. These light, volatile compounds give an immediate burst of aroma.

The wax also impacts cold throw. Natural waxes like soy wax and beeswax have lower fragrance load limits than paraffin, so they may not project scent as well unlit. However, waxes with a higher oil content, like coconut wax, can improve cold throw.

Candle vessels also affect how well fragrance travels through the air when unburned. Containers that fully enclose the candle, like tin or glass jars, will concentrate fragrance better than open containers. The candle’s surface area exposed to air should also be considered.

Testing cold throw can be done simply by smelling an unlit candle. Compare scented and unscented candles, or candles with different wax, fragrance loads, and vessels to evaluate which performs best.

How HT and CT Interact

HT (high temperature) and CT (cold throw) are related but distinct properties in candle making. While high HT is important for clean wax burning and complete fragrance release, CT determines how well the candle’s scent spreads into a room. Balancing these two factors is key for a high-performing candle.

In general, there is an inverse relationship between HT and CT. Waxes and wicks engineered for a higher HT tend to have lower CT. Likewise, materials maximizing CT typically have lower HT. This is because HT depends on high wax pool temperatures, while CT is enhanced by ingredients that solidify and trap fragrance when cooled.

However, with careful testing and ingredient selection, it is possible to achieve a balance of strong HT and CT in one candle. For example, using wax with mid-range melt point paired with a properly-sized wick can allow hot enough pooling for fragrance release while retaining enough viscosity for ample fragrance throw when cooled. Testing different wax and wick types through burn trials is key to optimizing both HT and CT.

In the end, finding the right equilibrium of HT and CT for each candle formulation takes trial and error. But the effort pays off through candles that fill a room with fragrance from top to bottom burn.

Choosing Waxes Based on HT and CT

When selecting waxes for candle making, it’s important to understand how they perform in terms of HT (high temperature) and CT (cold throw). Different waxes have unique properties that influence both the hot and cold scent throw of the finished candle.

Paraffin wax typically has excellent HT due to its high melting point, allowing it to hold fragrances well when burned. However, paraffin has poor CT since it doesn’t retain or release scents efficiently at room temperature. For stronger CT, it’s best to blend paraffin with wax that has better cold throw properties.

Soy wax has medium to high HT and CT, making it a versatile blended wax. The HT and CT can vary between different soy waxes, with hydrogenated soy wax performing better than natural soy. The drawback is soy wax’s lower melting point compared to paraffin.

Palm wax is known for its excellent CT since it readily absorbs and releases fragrance oils. The HT is relatively low due to the low melting point. Combining palm wax with paraffin or soy helps increase the HT for a candle with balanced hot and cold throw.

Beeswax has medium HT but high CT, allowing candles to have vivid cold throw. The challenge is beeswax’s low melting point, so pair it with harder waxes. Gel wax delivers high HT and CT, although it can be more difficult to work with compared to other waxes.

Testing waxes with different property combinations allows candle makers to find the ideal balance of HT and CT. Record burn results for each wax blend to determine which provides the strongest hot and cold throw for the candle. With informed wax selection, achievable HT and CT goals can be met.

Wick Selection for HT and CT

Properly pairing the wick with the wax is critical for achieving the ideal HT and CT in a candle. Wick selection involves balancing the flame size and heat output (HT) with the wax pool temperature and fragrance diffusion (CT).

For a strong HT, a larger wick is needed to produce a taller flame. However, too large of a wick can create excessive melt pools resulting in poor CT. On the other hand, a smaller wick produces a lower HT but allows for a more ideal wax pool for fragrance throw.

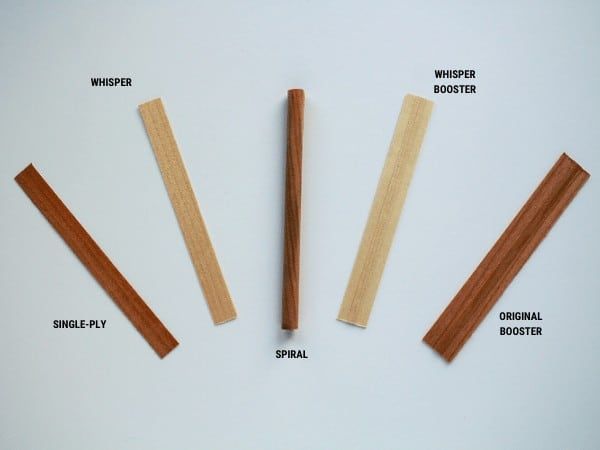

The most common wick types and their characteristics are:

- CD wicks – All-purpose medium sized wicks good for balancing HT and CT

- LX wicks – Large wicks that produce high HT but can sacrifice CT

- HTP wicks – Extra-large wicks maximizing HT with very high flames

- ECO wicks – Smaller wicks focusing more on an ideal CT over high HT

Wick sizing, denoted by numbers, also impacts HT and CT. Higher numbers indicate thicker, larger wicks while lower numbers are smaller, thinner wicks. A good starting point is to match the wick number to the diameter of the container.

Testing wicks is key. The same wax may need different wicks depending on the candle’s diameter and container material. Achieving the perfect HT and CT is a balance and may take some experimentation with different wick types and sizes.

Container Considerations

The container that holds the wax and wick plays an important role in managing heat transfer and fragrance dispersal. Glass, metal, and ceramic containers conduct heat away from the melting pool more readily than containers made of wood, paper, or plastic. This means the melting pool reaches a higher temperature in non-conductive containers, resulting in more complete wax consumption and a stronger hot throw. However, heat buildup in non-conductive containers can also lead to issues like soot and tunneling.

Container shape and size affects the melt pool surface area and temperature gradient, changing hot throw intensity. Smaller containers concentrate fragrance but limit melt pool size. Larger containers allow a bigger melt pool but may dilute fragrance. The ideal container matches the candle’s wax volume and wick size.

For cold throw, containers with more headspace above the candle allow fragrance to accumulate when the candle is not lit. Tighter lids also help retain cold throw. Porous materials like cement can absorb fragrance oils, reducing cold throw. The candle container should complement the wax formulation for optimal hot and cold throw.

Testing and Troubleshooting

Testing and troubleshooting your candle’s hot and cold throw is an important part of achieving the ideal burn and fragrance experience. Here are some methods to test and improve HT and CT:

For hot throw, observe the wax pool as the candle burns. A full, even melt pool indicates good HT. Sooting, tunneling, or an uneven melt pool suggest issues with HT. Try a larger diameter wick to increase HT.

For cold throw, smell the unlit candle from various distances. A strong scent up close but weak from further away indicates poor CT. Try adding more fragrance oil or using a different wax blend to improve CT.

Test HT and CT in different size containers. The ideal combination for a votive may be too much or too little for a large pillar. Adjust wicks and fragrance to balance HT and CT in each container.

Conduct testing outdoors or in ventilated areas. HT and CT may differ in enclosed spaces. Test in realistic environments to troubleshoot issues.

Record your testing details like wax type, fragrance load, wick size, and room conditions. Compare results to optimize HT and CT.

Achieving Ideal HT and CT

Finding the right balance of HT and CT for your candle can take some trial and error. Here are some tips and tricks from expert candle makers on dialing in the perfect HT and CT:

Start by choosing a wax with a natural HT and CT that fits your needs. Paraffin wax tends to have a high HT but lower CT. Soy and coconut waxes generally have a lower HT but throw scent well. Beeswax and palm wax land in the middle with moderate HT and CT.

Mixing waxes can help balance HT and CT. A paraffin and soy wax blend will bring up the HT while retaining some CT. Adding a small amount of beeswax to soy can help strengthen scent throw without drastically increasing the HT.

Wick selection plays a key role in HT and CT. Smaller diameter wicks typically burn cooler with lower HT but can restrict scent throw. Going up one or two wick sizes often raises the HT and CT. Testing wicks to find the optimal size for your wax blend is recommended.

Jar shape and size impacts HT and CT. Deeper and skinnier containers allow for a stronger HT in the concentrated space. Short wide jars can result in a weaker HT. Match your wax, wicks and jars so the HT reaches the top but doesn’t overheat.

Curing candles for at least 2 weeks before burning allows the scent and wax structure to stabilize, producing better HT and CT. Test burn each candle to ensure an ideal melt pool and burn. Trim wicks as needed to fine tune the HT and CT.

Finding the right balance takes experimenting until you dial in the perfect HT to fill the room with fragrance along with an ideal melt pool for the CT and burn characteristics you desire.

Conclusion

When making candles, finding the right balance between a candle’s hot throw (HT) and cold throw (CT) is crucial for achieving optimal performance. HT refers to a candle’s fragrance intensity when lit, while CT describes the fragrance strength when unlit. While a strong HT fills a room with aroma when burning, an appealing CT entices people before lighting.

Several factors influence a candle’s HT and CT balance. Wax selection plays a key role, as different waxes melt at varying temperatures to release fragrance. Wicks also impact HT based on their diameter and material. Proper wick sizing promotes full wax pooling for fragrance diffusion. Container choice can affect both HT and CT. Tightly covered vessels trap more unlit fragrance, while open containers allow more fragrance escape when lit. Testing candles is critical for gauging HT and CT strength.

In summary, crafting candles with an ideal balance of hot and cold throw requires careful testing and adjustment of waxes, wicks, vessels, and other variables. When these elements are harmonized, candles perform at their peak, delighting the senses both before and during lighting.