What Diameter Is An Eco 10 Candle Wick?

Candle wicks are crucial components of candles that serve several important functions. The wick is a piece of string or cord that runs through the center of a candle. Its main purpose is to deliver fuel to the flame by drawing wax up through capillary action. As the wax is drawn up the wick, it vaporizes and combusts at the tip to form the candle’s flame.

Wicks also help regulate the candle’s burn rate and wax pool temperature. Thicker wicks typically burn hotter and create a larger flame and wax pool compared to thinner wicks. The size and material of the wick determines how quickly it burns and absorbs wax. Wicks that are properly sized relative to the candle diameter will burn at an ideal rate without excess smoke, soot, or flame height.

Choosing the proper wick is essential for optimal candle performance and safety. The thickness or diameter of the wick must be carefully matched to the diameter of the candle container. ECO wicks are a common type of braided cotton wick used for container candles. Understanding the standard ECO 10 wick diameter will help candle makers select the ideal wick for their projects.

What is an ECO 10 Wick?

ECO 10 wicks are a type of candle wick often used in container candles. The “ECO” stands for “Eco-Cotton” which refers to the material the wick is made from – unbleached cotton fibers coated with paraffin wax.

ECO 10 wicks have a flat, braided design that promotes full melt pool burning and helps prevent clogging. They are designed to curl over as they burn, which directs the flame into the wax pool. This helps ensure clean, even burning with no excess smoke.

The “10” in ECO 10 refers to the thickness or diameter of the wick. An ECO 10 is approximately 10 ply, meaning it has 10 individual cotton strands braided together to create the wick. This gives it a thicker diameter than smaller ECO wicks like ECO 2 or ECO 4.

The larger diameter of an ECO 10 makes it ideal for container candles with wider diameter jars or heavier wax blends. The thicker wick helps ensure proper melting and full wax pool formation in larger candles.

Typical Diameters

The ECO 10 wick is available in several standard diameters. According to The Flaming Candle, the most common diameters are 4mm, 5mm, and 6mm (ECO-10 6” Pre-tabbed Wick).

Hive and Honey Candle Co. also confirms that the ECO 10 comes in 4mm, 5mm, and 6mm diameters for their pre-tabbed wicks (ECO 10 6″ Pretabbed Wick).

According to Candlewic, the 8″ ECO 10 wicks come with a 6mm diameter neck (Container Wicks – Wick size & type: 8″ ECO-10 (100)). This indicates that the 6mm diameter is a common choice even for longer ECO 10 wicks.

So in summary, the most widely available and commonly used ECO 10 wick diameters are 4mm, 5mm, and 6mm.

How Diameter Impacts Burning

The diameter of a candle wick directly impacts the size of the flame and the burn time. According to research by Furlong (2023) [1], a larger wick diameter results in a larger flame and faster burn time. This is because a thicker wick can absorb and deliver wax to the flame at a higher rate, fueling a larger flame. In contrast, a smaller diameter wick restricts wax flow, resulting in a smaller flame and slower burn.

As an example, testing by Furlong found a 1/16″ cotton wick produced a flame height of 1.4″ and burned for 32 hours, while a thicker 3/16″ wick had a taller 2.1″ flame and faster 25 hour burn time. This demonstrates how doubling the wick thickness can increase flame height by 50% while decreasing burn time by 22%.

Therefore, selecting the proper wick diameter is crucial for achieving the desired flame characteristics and burn time. A thickness should be chosen that suits the candle size and composition. Too small of a wick will produce a weak flame and tunneling issues, while too large of a wick can result in overflow, poor scent throw and fire hazards.

Choosing the Right Diameter

There are several factors to consider when selecting the right diameter for an ECO 10 wick:

Wax type – Different wax types melt at different temperatures, which impacts the diameter needed. Softer waxes like soy wax require a smaller diameter wick than hard waxes like paraffin.[1]

Candle size – Larger candles need wider wicks to ensure sufficient fuel. As a rule of thumb, use a larger wick for containers over 3 inches wide.[2]

Burn time – For longer burn times, a slightly larger wick creates a stronger flame and molten pool. Shorter burn times may only need a smaller wick.[1]

Fragrance level – Heavily scented candles need wider wicks so the fragrance isn’t drowned out by a weak flame.[2]

Additives – Additives like vybar or stearic acid that harden wax require a wider wick.[1]

Testing is key to optimize the diameter for each unique candle recipe and specifications.

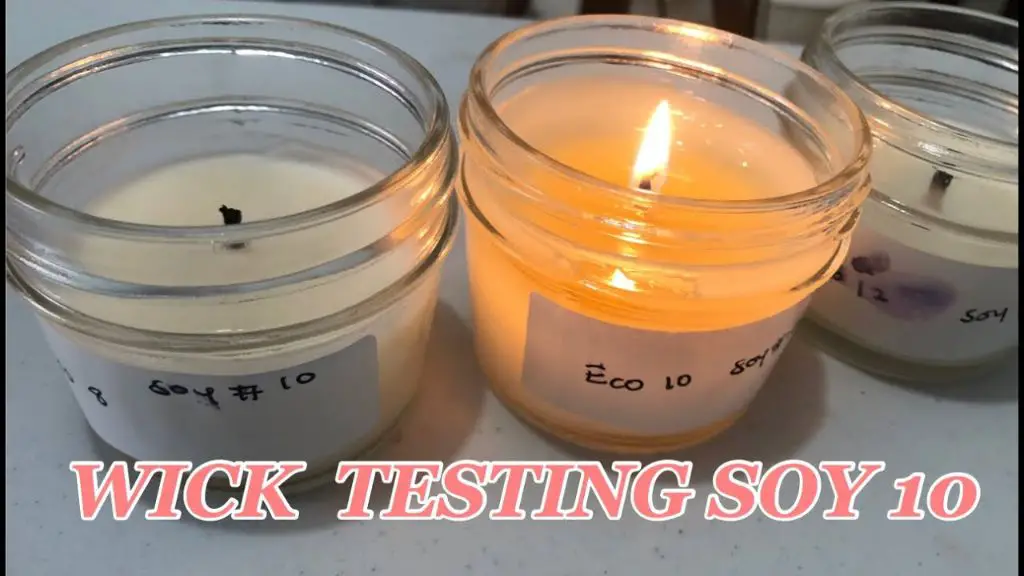

Testing Different Diameters

When using ECO 10 wicks, it’s important to experiment to find the optimal wick diameter for your specific type of candle. The diameter impacts how the melted wax pools and climbs up the wick, which affects the flame height and burn properties.

A thinner 3/0 wick will create a smaller melt pool and lower flame height, while a thicker 1/8″ wick will generate higher heat and a taller flame. Testing candles with the same wax, fragrance load, and vessel, but with ECO 10 wicks of varying diameters, allows you to observe the differences firsthand. Most candle makers recommend starting with a 1/16″ or 5/0 diameter wick for a standard ECO 10 candle wick and adjusting up or down from there based on your testing.

Keep wick samples on hand in several diameters when testing. Wicks that are too small can lead to poor scent throw or tunneling, while wicks too large can result in sooting, mushrooming, or an unsafe flame. The ECO 10 wick type gives some flexibility in diameter while maintaining a flat, rigid structure. With testing, you can dial in the ideal diameter for the wax, fragrance, colorants, and vessel shape used in your candle.

Troubleshooting

If you encounter issues when burning a candle, it could potentially be caused by an improper wick diameter. Some common troubleshooting tips for wick-related problems include:

If the candle flame is too small or keeps going out, the wick may be too small for the wax and container. Try going up one or two wick sizes to allow for a larger flame. As a source suggests, “Wick size is too small. Use larger wick size or try a different wick type.” (https://www.theflamingcandle.com/troubleshooting/)

If the candle flame is too large, producing excessive smoke or soot, the wick is likely too large for the wax and jar. Go down a wick size or two to prevent overheating the wax. According to one source, “If the wick is too large, the wick will consume too much fuel too quickly, causing it to generate too much heat and melt right down the middle of your candle.” (https://www.candlescience.com/wax/soy-wax-trouble-shooting-guide/)

Testing a few different wick sizes to find the optimal balance for your wax type, fragrance load, and candle vessel is key. Adjust the diameter up or down until you achieve the best burn with no issues.

Safety Considerations

When burning any candle, it’s important to follow basic safety precautions to prevent fires or other issues. This is especially true when using ECO 10 wicks, as their larger diameter requires extra care.

According to Beeswax Candle Wick, Safety Wick, 200 Feet for DIY …, ECO 10 wicks should only be used in containers that are at least 3 inches in diameter. The larger the candle holder, the better, as this gives more room for the flame to breathe and prevents overheating.

It’s also critical to trim wicks to 1⁄4 inch before each lighting to avoid flare ups, as recommended by US7293984B2 – Self extinguishing safety candle wicks and …. Allow the wax pool to form completely across the top of the candle before relighting trimmed wicks.

Never leave a burning candle unattended. Keep it away from drafts and vents that could cause the flame to tunnel down and ignite the holder or table below. Place on a stable, heat resistant surface at least 3 feet from anything flammable.

With some basic precautions, ECO 10 wicks can burn safely and provide great illumination. But be sure to follow the manufacturer’s recommendations for proper use.

Other Wick Options

While ECO 10 wicks are a popular choice for soy candles, there are some other common wick options to consider:

CD wicks are another type of flat, cotton coreless wick that work well with vegetable waxes like soy. They come in a range of sizes similar to ECO wicks. CD 5, 7, 9, and 12 wicks are comparable to ECO 4, 6, 8, and 10 sizes (Source).

Wooden wicks are made from natural wood fibers and add an audible crackling sound as the candle burns. Popular wood wick sizes are WW 4/0, WW 8/0, and WW 16/0. The wood wick diameter is slightly larger than an equivalent numbered cotton wick (Source).

Zinc or metal core wicks are also an option, though less common for soy candles. They offer good scent throw but need to be kept short to prevent soot. Popular zinc wick sizes are ZC 3 and ZC 4.

Testing different wick types and sizes for your specific wax, fragrance, and vessel is recommended to find the best option.

Conclusion

In summary, selecting the proper wick diameter is crucial for safe, effective candle burning. An ECO 10 wick typically comes in diameters ranging from 6mm to 15mm. Choosing a diameter on the smaller end, around 6-8mm, is usually best for container candles like jars or tins. This provides a smaller flame that reduces issues like tunneling, smoking, or sooting. Larger diameters around 12-15mm can overpower container candles and cause more safety risks. Testing different diameters to find the optimal one for your specific candle design is advised. With the right wick diameter, you’ll get a candle that burns cleanly and evenly down to the bottom. This results in maximum fragrance release and an enjoyable experience for the user. In the end, putting in the effort to find and use the ideal wick diameter makes all the difference in candle performance.