What Are Poured Candles?

What Are Poured Candles?

Poured candles are candles that are created by manually pouring melted wax into a container or mold 1. The wax is melted in large quantities, mixed with fragrance and dye, and then carefully poured into each individual candle vessel. This handmade production method contrasts with candles made through an automated pouring process. Poured candles allow for creativity and customization in scent, color, and shape.

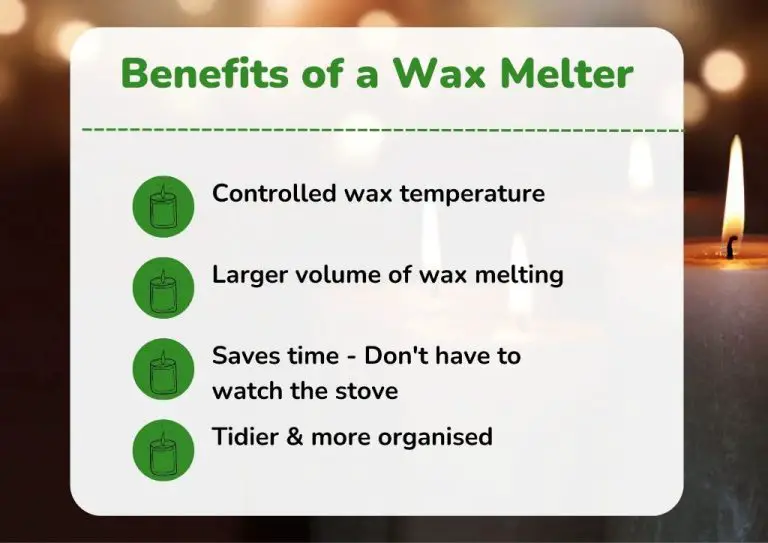

Poured candles may be made from various types of wax, like paraffin, soy, or beeswax. The wax is melted using a double boiler or wax melter. Once melted, the wax can be mixed with fragrance oils and liquid dye to achieve the desired scent and color. Popular vessel options include glass jars, tins, and decorative ceramic containers. The candle wick is centered before pouring the wax. The wax cools and hardens into a solid candle. Poured candles are often finished with decorative elements like labels, trim, or packaging.

The term “poured candle” indicates a handcrafted, artisanal production method, as opposed to mass manufactured candles. Poured candles allow makers to offer custom scents and vessels in small batches. The handmade process results in candles with a unique look and personality. Many consumers seek out poured candles for gifts, home decor, or their therapeutic aromas.

How Poured Candles Are Made

The basic process for making poured candles involves melting wax, adding fragrance and dye, pouring into containers with wicks, and allowing to fully cure and cool before use. Wax such as paraffin, soy, or beeswax is melted using a double boiler or melter to the proper temperature. Once melted, dyes and fragrances can be added and mixed in. Wicks are inserted into candle containers or molds, which are then filled by pouring in the melted wax mixture. As the wax cools, it solidifies around the wick. Once fully cooled and set, the finished candles are removed from molds and can be decorated as desired before use. Proper preparation of materials, melting points, pour temperatures, cooling conditions, and curing times are key factors in creating successful poured candles.

Source: https://www.shopify.com/blog/how-to-make-candles

Types of Waxes Used

There are several types of waxes that can be used to make poured candles:

Paraffin Wax

Paraffin wax is the most common candle wax. It is a petroleum byproduct made from refined crude oil. Paraffin wax is relatively inexpensive and makes a long burning, high quality candle. It has a great capacity to hold fragrance and dye. The drawback is that paraffin wax releases more soot than other waxes when burned.

Soy Wax

Soy wax is made from hydrogenated soybean oil. It is a renewable and clean burning wax alternative to paraffin. Soy wax burns slower and cooler than paraffin wax. It can hold color and fragrance well, but not quite as effectively as paraffin. Soy wax is also more prone to frosting.

Beeswax

Beeswax is a natural wax produced by honey bees. It has a pleasant natural honey aroma. Beeswax candles burn brighter and longer compared to other waxes. However, beeswax is expensive and difficult to work with because it has a high melting point.

Palm Wax

Palm wax comes from the fruit of palm trees. It is eco-friendly, biodegradable, and vegan. Palm wax burns clean without producing much smoke. It holds scent very well. The drawback is that palm wax has a low melting point and candles made from it can lose their shape in warm environments.

Adding Scents and Colors

Scents and dyes are key ingredients that help make poured candles unique and appealing. Adding scents is one of the easiest ways to customize candles. Most candle makers use concentrated fragrance oils specifically formulated for candles – usually adding 1-2 ounces of fragrance per pound of wax according to manufacturer recommendations (https://www.brambleberry.com/how-to/candles/art0152-color-candles.html). The fragrance oils are simply blended into the melted wax before pouring the candles.

Candle dyes also allow for creative customization of candle colors. Typical options for coloring candles include candle dye blocks, liquid candle dyes, powder dyes, candle color blocks, and even crayons. Candle dye flakes or liquid dyes provide the most vibrant colors. When adding dyes, it’s best to start with just a small amount – 3-4 drops or pinches – and then test the color before adding more as needed. Getting an even color distribution requires thoroughly mixing the dye into the wax when melted. Both dyes and fragrances should be added when the wax is completely melted and just before pouring candles (https://helloglow.co/how-to-color-candles/).

Wicks

The wick is a crucial component of poured candles. The right wick helps ensure proper burning and an even melt pool. Wicks are made from different materials and come in varying thicknesses.

Materials

Wicks can be made from cotton, paper, or wood. Cotton is the most common wick material for poured candles. Cotton wicks are soft and flexible, and they burn cleanly without releasing odors or soot. Paper and wood wicks are less commonly used.

Sizing

Wick sizing is important for even burning. Thicker wicks are used for larger diameter candles or candles with added elements like glitter that can clog the wick. Taller candles also require thicker wicks to ensure sufficient wax liquefaction. Generally, taper candles use smaller wicks while pillar candles use larger wicks.

Wick Types

Common wick types include:

- Flat braided wicks – Made by braiding several cotton threads for rigidity.

- Square braided wicks – Braided wicks with a square cross-section.

- Cored wicks – Cotton wicks with a stiff core for stability.

- Tabbed wicks – Flat wicks with tabs for centering in the wax.

The wick type impacts wax pooling, rigidity, and burning characteristics. Testing different wicks to find the optimal size and style is key.

Molds

Molds provide the shape for poured candles. Molds can be made from various materials like aluminum, tin, glass, silicone, plastic, wood, or plaster1. Silicone molds are a popular choice as they are flexible and easy to remove candles from. Harder molds like metal or glass need to be prepared with a mold release spray.

Molds come in endless shapes like pillars, tapers, votives, containers, novelty shapes, and more. The mold’s shape will determine the final candle design. Round, square, star, heart etc. Specialty molds can create shaped or sculpted candles.

Before pouring wax into a mold, it should be cleaned and any seams smoothed. Metal molds can be rinsed with boiling water to warm them up which helps wax spread and release easier. Silicone molds should be lightly coated in oil or mold release spray. Preparing the mold is an important step for clean unmolding.

Cooling and Curing

Proper cooling and curing are important steps when making poured candles. After pouring the wax into the mold, the candles need time to cool and harden. Cooling allows the wax to solidify and takes around 6-12 hours depending on the size of the candle and wax type. Curing then allows the crystals in the wax to stabilize over 1-2 weeks. This results in an even burn when the candle is lit.

According to The Armatage Candle Company, curing is the continual change of a wax after the initial cooling period. Waxes like soy harden and become stiffer over time which requires more energy to melt when burned. Allowing time for curing allows the wax and fragrance to bind together fully. Fragrances can also slightly change during the curing process.

Proper curing produces candles that burn longer and more evenly. The general recommendation is to allow poured candles to cure with the lids off for 1-2 weeks before use. Bramble Berry suggests a minimum of 48 hours if lids are left on. Beeswax candles may require slightly longer curing times closer to 2 weeks. Paying attention to cooling and curing will result in quality poured candles with an ideal burn.

Safety

When pouring and making candles, it’s important to follow safe practices to avoid injuries, burns, and fires. Here are some key tips for pouring candles safely:

Wear protective equipment like shoes, long pants, and aprons when pouring hot wax to prevent skin burns (Candle Making Safety Tips). Ensure your workspace is clear of clutter and be cautious when handling hot wax.

Only use appropriate heat-safe containers for pouring candles that won’t crack or leak when filled with hot wax (5 Candle Making Safety Tips). Never pour wax into glass that could shatter from heat.

Practice good fire safety by keeping flammables away from open flames. Never leave burning candles unattended. Keep wicks trimmed to 1⁄4 inch to prevent excess smoke and dripping. Allow candles to fully cool and harden before moving or packaging.

Educate yourself on proper wick sizing to avoid tons of excess smoke. Test candles before selling or gifting. With smart pouring and fire safety practices, candle making can be an enjoyable hobby.

Decorating and Packaging

A poured candle can serve not just as a functional light source but as a beautiful decorative accent as well. After the candles have cooled and cured, there are many creative ways to embellish and enhance their visual appeal.

One popular decorating technique is to add botanicals or decorative objects to the top of the candle. Dried flowers, herbs, seashells, beads, sand, glitter, and more can be affixed to the top of the candle with a bit of melted wax. This adds color, texture, and visual interest.

Candles may also be dressed up by carving, sculpting, or etching designs into the surface of the wax. Geometric patterns, words, or images can be carved to make each candle unique. Wax paints can also be used to hand-paint the candle surface.

To finish, candles are typically packaged in glass containers, metal tins, or decorative boxes. The packaging should protect the candle while also coordinating with the style of the candle itself. Clear glass allows the colors and shapes of the candle to show through. Metal tins or textured boxes add more flair. Custom labels can identify scents and designs.

With countless options for embellishing and packaging, poured candles can become true decorative objects and gifts. A plain candle transforms into a beautiful centerpiece, decoration, or display piece with the right creative touches.

Uses for Poured Candles

Poured candles like votives, pillars, and containers have many uses. Votive candles are small candles typically used in candle holders. Their size makes them versatile for decorating and creating ambiance. Pillar candles are tall, cylindrical candles that stand on their own. They come in various sizes and burn times, making them ideal for centerpieces and focal points. Container candles are poured into jars or other vessels, blending the candle with decorative holders. This allows for creativity in color, scent, and decoration. Container candles make great gifts.

Candles also provide lighting and are used in religious or spiritual rituals. Their warm glow creates a calming atmosphere. The scented varieties release aroma-therapeutic fragrances into the air when burned. People often light candles to set a mood, relax, or create a spa-like experience at home. They can also help mask odors or freshen indoor air.

In summary, poured votive, pillar, and container candles serve various decorative, spiritual, therapeutic, and practical lighting purposes (source). Their shapes, sizes, burn times and vessel options allow people to use them creatively to enhance their environments and activities.