Is Soap Base The Same As Lye?

What is Soap Base?

Soap base is a premade mixture of oils, fats, and other ingredients that can be used to create handmade soaps without having to start from scratch. It contains all of the basic ingredients needed to produce soap, but without the lye (sodium hydroxide).

Common ingredients in soap base include:

- Oils like coconut, palm, olive, safflower, sunflower, hemp seed, castor

- Natural butters and waxes like shea, cocoa, mango, beeswax

- Glycerin

- Sorbitol

- Purified or distilled water

- Botanicals like aloe vera, chamomile, oatmeal

There are a few main types of soap base:

- Melt and pour – Comes in solid blocks that can be melted, customized, and poured into molds.

- Liquid or cream – Has a smooth, fluid texture and can be poured directly into containers.

- Hot process – Is cooked and goes through saponification but without any excess lye.

Soap base allows hobbyists and small businesses to make custom soaps easily without handling lye. It provides a shortcut while still allowing for creativity in additives like scents, colors, and decorations.[1]

What is Lye?

Lye is a caustic chemical solution made from a soluble alkaline base. The most common form is sodium hydroxide (NaOH), but potassium hydroxide (KOH) can also be used to make lye solutions. Lye has a pH level of 13-14, making it highly alkaline and corrosive to organic materials like skin, eyes, and lungs [1].

The main uses of lye include:

- As a drain cleaner to dissolve grease clogs

- In the production of soaps and detergents

- To cure olives and pretzels

- In biodiesel production

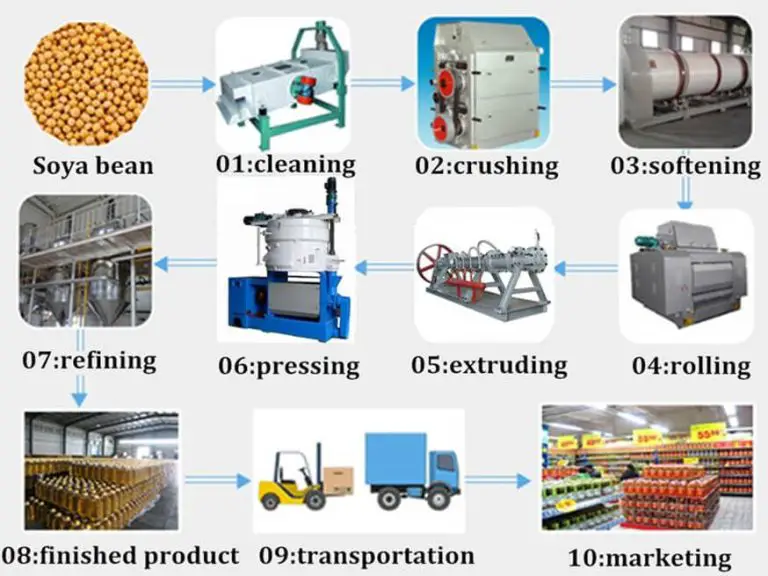

Traditionally, lye was made by leaching wood ashes in water, producing a solution of potassium hydroxide. Today most lye is industrially produced from the electrolysis of brine solutions. The raw materials include sodium chloride (table salt) and water, which are combined and electrolyzed to produce chlorine gas and sodium hydroxide. This is condensed, purified and pelletized to make sodium hydroxide lye [2].

Difference Between Soap Base and Lye

There are some key differences between soap base and lye:

- Soap base contains lye, but also has other ingredients like oils, glycerin, and fragrances. Lye is a single chemical ingredient – sodium hydroxide.

- Soap base comes premixed and ready to melt and mold into bars. Lye requires combining with oils and going through saponification to turn into soap

- Soap base is safe to handle and work with in melt and pour soap crafting. Pure lye requires safety precautions due to its caustic nature and ability to cause chemical burns.

- The lye in soap base has already reacted with the oils through saponification. Pure lye remains a harsh base that needs to undergo the chemical reaction.

- Soap base results in a gentle, moisturizing bar of soap. Lye soap requires extra care to create a skin-friendly bar, but allows for more recipe customization.

In summary, soap base contains lye but also provides additional beneficial ingredients not found in pure caustic lye. Lye requires processing into soap, while soap base comes ready to melt and mold. Both contain sodium hydroxide, but soap base presents it in a pre-saponified mild form (https://www.cedarwitchgoods.com/blogs/news/all-soap-is-made-with-lye-cold-process-vs-glycerin-melt-pour-soaps).

Lye in Soap Making

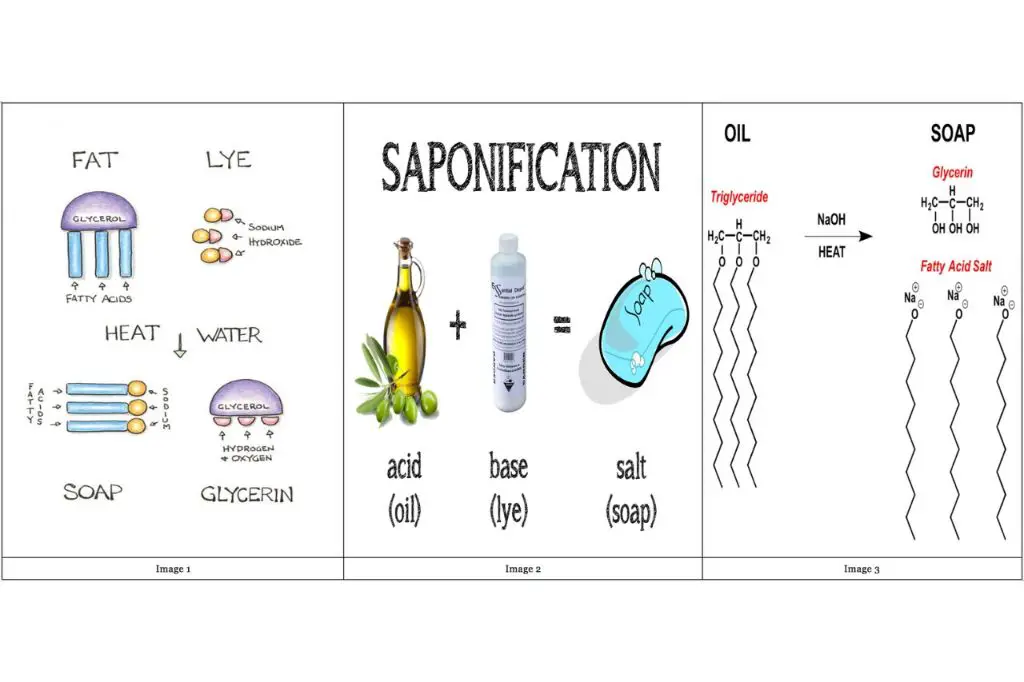

Lye plays a crucial role in the soap making process through a chemical reaction called saponification. Saponification is the process whereby lye reacts with oils and fats to turn them into soap. Specifically, the hydroxide ions in lye react with the fatty acids in oils to form soap molecules. The lye itself gets used up in this chemical reaction.

During saponification, the lye breaks down the chemical bonds in the triglycerides that make up fats and oils. The fatty acids get separated from the glycerol backbone and then bond with the hydroxide ions from the lye to form soap. Meanwhile, the glycerol gets left behind in the soap mixture as a byproduct. So in summary, lye is the catalyst that drives the saponification reaction to turn oils into soap.

When handling lye it is crucial to take proper safety precautions. Lye can cause severe skin and eye burns when it comes in contact in its raw form. Protective gloves, eye wear, and clothing should always be worn. Lye should also be handled in a well-ventilated area since breathing in the fumes can irritate lungs. Never add water to lye, instead add lye to water to prevent violent reactions. Allow all lye mixtures to fully cool before using in soap making. With proper handling, lye can be used safely in soap production.

Sources:

Soap Bases in Soap Making

Using soap base in soap making simplifies the process because it already contains the main ingredients needed to make soap. The functions of soap base include nourishing the skin, producing lather, and cleaning effectively. Some key benefits of using soap base include:

- Convenience – Soap base eliminates the need to handle lye or go through a complex saponification process.

- Customization – Soap makers can add colors, scents, and ingredients like oils or butters.

- Accessibility – Beginner soap makers can easily start with a soap base.

- Time savings – Formulating with soap base is faster than starting from scratch.

There are many creative ways to use soap base. Melt and pour is a popular technique where the soap base is melted, mixed with additives, and poured into molds. Handmilled soap can be created by grating soap base and mixing in elements like botanicals. Soap base can also be used in soap making methods like hot process and cold process by replacing the lye solution. Some advanced techniques include creating multi-colored swirls, embeds, and fun shapes like soapsicles.

The versatility of soap base allows endless possibilities to make fun and artistic soaps. Soap makers can explore different formulations and creative designs without handling lye, opening up soap making to more people.

Pros and Cons of Lye Soap

Lye soap has several benefits compared to commercial soaps. First, lye soap is all natural and free from added chemicals or preservatives. The main ingredients in lye soap are oils and fats combined with a lye solution. This makes lye soap gentle and nourishing for the skin (1). Lye soap also has effective antibacterial and antimicrobial properties due to the alkaline pH of the lye. This helps cleanse the skin thoroughly and prevent the spread of germs (2). Many people find the old-fashioned lye soap bars leave skin feeling refreshed and soft.

However, there are some drawbacks to lye soap to consider. The lye used in the soap making process can be very dangerous if handled improperly. Creating lye soap should only be done by experienced soap makers taking proper safety precautions (3). There is a risk of skin irritation or burns if the lye is not fully saponified during the soap making process. Some people may find lye soap overly drying for sensitive skin. The bars also have a shorter shelf life and need to cure for several weeks after being made. Fragrances, colors, and additives are difficult to incorporate into cold process lye soaps.

Overall, while lye soap has some excellent cleansing and moisturizing properties, the drawbacks for beginner soap makers are the use of caustic lye in the soap making process and potential skin irritation for those with sensitivities. With care and experience, lye soap can be an ideal option for an all-natural skin care product.

Pros and Cons of Soap Bases

Soap bases provide some significant advantages compared to making soap completely from scratch. However, there are also some drawbacks to be aware of.

Benefits of Using Soap Bases

Some of the main benefits of using a premade soap base include:

- Convenience – Soap bases eliminate the need to handle lye or go through the complex process of cold process or hot process soapmaking. This saves a lot of time and effort.

- Beginner-friendly – Working with a premade base is much easier for beginners who want to make soap without the complications of lye. There is less equipment needed as well.

- No cure time – Soap made from a base does not require the typical 4-6 week curing period. It can be used right away.

- Consistency – Bases create consistent results and eliminate batch-to-batch variability compared to from-scratch soapmaking.

- Lower startup costs – Purchasing a soap base avoids the need to buy all the oils, lye, and equipment to make soap from scratch.

For hobbyists, beginners, or those wanting to quickly create soap, bases provide an accessible option without the complexities of lye soapmaking.

Drawbacks of Soap Bases

However, there are some limitations to be aware of when using a soap base:

- Less customization – There is less ability to customize the oils/fats compared to cold process soap. The properties of the base are fixed.

- Preservatives – Bases often contain added preservatives for a longer shelf life.

- Not all natural – Bases may contain synthetic ingredients whereas lye soaps can be made with all natural ingredients.

- Higher cost – Buying a premade base is often more expensive than making soap from scratch.

- Quality – Some mass-produced bases are lower quality than a handcrafted lye soap.

For those wanting full control and customization over the entire soapmaking process, lye soapmaking may be preferable despite the extra effort required.

Lye Soap vs Soap Base

Lye soap and soap base are two different methods for making handmade soap. The main difference is that lye soap is made completely from scratch using oils/fats and lye water. Soap base starts with a premade glycerin soap base and allows you to customize it with colors, scents, and additives.

Lye soap involves combining oils/fats with a lye solution through a chemical process called saponification. This requires carefully measuring ingredients, mixing them correctly, and going through gel and cure phases over 4-6 weeks before the soap is ready to use. Lye soap allows for full customization of the oil blend and qualities of the final bar. However, there are safety considerations when working with lye (source).

Soap base provides a shortcut by starting with a premade glycerin soap base. The soapmaker simply melts the base, adds preferred colors, scents, and additives like oils or botanicals. This method skips the lye process and saponification reaction. The soap hardens quickly and has a faster turnaround time compared to lye soap. However, there is less flexibility to customize the soap qualities (source).

Lye soap is recommended for soapmakers who want full control and customization. Soap base is better for beginners, for quickly making decorated soaps, or for avoiding lye. Both methods produce handmade soap, simply via different processes.

Safety Considerations

When making soap from scratch using lye, it is crucial to follow safety precautions. Lye is highly caustic and can cause serious burns if it comes into contact with skin and eyes. Always wear protective gear like goggles, gloves, long sleeves, pants, and closed-toe shoes when handling lye. Work in a well-ventilated area since lye can release toxic fumes. Never add water to lye, always add lye to water to prevent violent reactions. Allow your lye mixture to cool before adding oils. Clearly label and store lye out of reach of children and pets.

Though soap bases contain no free lye, safety measures should still be taken. Melted soap base is hot and can cause burns. Wear gloves when handling melted soap. Work in a well-ventilated area since some soap bases may release fumes when melted. Cool soap bases completely before removing from molds. Properly label soap containing food oils like olive oil since this can go rancid over time. Store soap bases in a cool, dry area away from direct sunlight. Keep all soap-making ingredients including soap bases locked up and out of reach of children.

By using caution and following standard safety practices, both handmade lye soap and melt-and-pour soap bases can be crafted safely.

Summary

To recap, soap base does not actually contain lye. While lye is a necessary ingredient in making handmade soap from scratch, commercial soap bases are manufactured differently and the lye is neutralized and converted during saponification so that the end product no longer contains any active lye.

The key differences between soap base and lye are:

- Soap base is the ready-to-use foundation for making melt and pour soap. Lye is the raw chemical used to make soap from scratch through cold process or hot process methods.

- Soap base is safe to handle and work with. Lye can cause severe burns if handled improperly.

- Soap base creates soap through a melting process. Lye creates soap through a chemical reaction called saponification.

- Soap base does not require exact measurements or complex processes. Lye soapmaking requires safety equipment, precise measurements, and extensive knowledge.

The main similarity is that both soap base and lye are used in creating handmade soap, just through different methods. While the lye is washed away after saponification in cold process soapmaking, melt and pour soap skips this step by using a pre-made soap base.