Is Candle-Making A Manufacturing Business?

Candle making dates back over 5,000 years, with the earliest known candles being made from whale fat. Today, candle making has grown into a major global industry worth billions of dollars. But is modern candle making still a true manufacturing business?

In this article, we’ll explore the full process of making candles on a commercial scale. We’ll look at the tools, equipment, regulations, and distribution channels involved to understand how candle production has evolved. By examining the scale and scope of operations, we’ll address the key question: Is candle making a manufacturing business today?

First, it helps to define what constitutes a manufacturing business. Manufacturing refers to the large-scale mechanical or chemical transformation of materials into new products. Manufacturing businesses use powered machinery, factory assembly lines, and standardized processes to mass produce goods. They require significant capital investments in facilities, equipment, and labor.

History of Candle-Making

Candle-making dates back thousands of years, with the earliest known candles originating in ancient Egypt and China where they were made from whale fat, beeswax, and tallow (rendered animal fat). Candles were initially developed as a practical source of lighting, before taking on ceremonial and spiritual significance in many cultures. The Egyptians used rushlights and torches, while the Chinese created candles from whale fat and plant wicks. The Romans learned candlemaking from the Egyptians, improving the process by using tallow. Beeswax candles were later introduced in Europe, being cleaner, brighter and odorless compared to other materials. The Middle Ages brought major improvements to candlemaking, with techniques developed for purifying beeswax and braiding wicks to reduce dripping. From the 18th century, spermaceti from sperm whales began replacing wax, until paraffin wax emerged in the 1850s as a modern cheaper alternative. With industrialization, candle manufacturing shifted from small home-based production to mass factory production 1. While primitive candle-making used crude methods like repeatedly dipping sticks in melted fat, today’s methods involve detailed processes ensuring quality, safety, and consistency.

Candle-Making Process

The basic candle-making process involves four key steps: preparing the wick, preparing the wax, pouring the wax, and finishing the candle. The raw materials needed are wax, wicking material, molds, and fragrance/dyes.

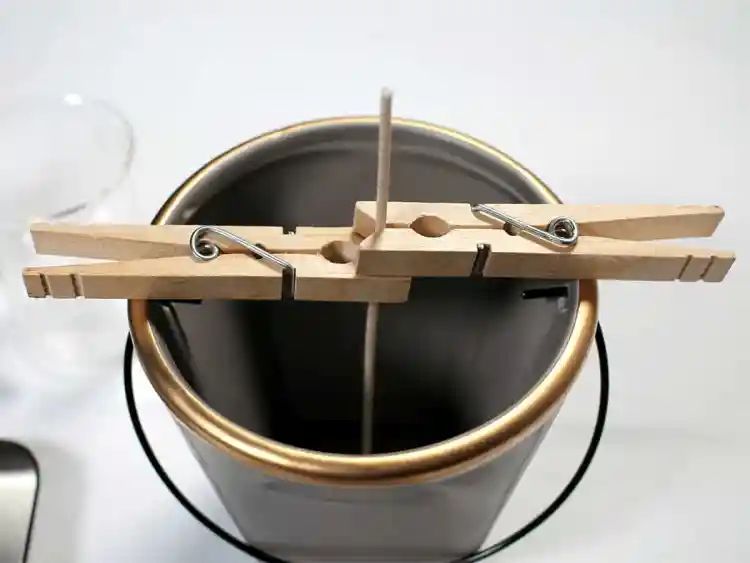

The wicking is an important part of the candle design. Wicks are made from materials like paper, cotton, or wood, and come in different thicknesses. Wicks need to be stiff enough to stand upright when embedded in the wax. They are cut to size based on the candle mold.

The wax goes through a melting process after being combined with dyes and fragrances. Paraffin wax is commonly used, derived from petroleum refining. Beeswax and soy wax are also options. The melted wax is poured into the molds around the wicking at temperatures between 160-200°F.

After pouring, the candles go through a cooling and finishing process. This allows the wax to fully harden and stabilizes the shape. The finishing steps can involve trimming the wick size, evening out the top surface, and adding decorative elements.

Scale of Production

The candle making industry includes a range of business models, from home-based businesses to large manufacturers. Home-based candle makers often produce candles in small batches with limited equipment. They may sell at local craft fairs or online in small volumes. Large manufacturers like Yankee Candle operate factories capable of mass production. They produce millions of candles per year sold through widespread retail distribution.

Production volume varies greatly between small home businesses producing dozens of candles per week to large factories outputting thousands of candles per day. Many small candle makers focus on custom or specialty candles, offering personalized designs, scents, or containers. They do not aim for mass production. Large manufacturers rely on efficiency and standardization to produce candles at scale for retailers and mass consumer markets. Their production volumes allow lower per unit costs but less customization.

So while large manufacturers churn out candles in an assembly line fashion, small candle makers handcraft candles in controlled batches. The scale of production is indicative of each business’s production capacity, goals, and competitive strategy in the candle making industry.

Tools and Equipment

Candle-making can be done with basic household items or more advanced equipment and machinery depending on the scale of production. At the most basic level, candle-making only requires a stove or hot plate, double boiler, thermometer, stirring spoons, molds, drying racks, and fragrance oils. However, larger manufacturers use more specialized equipment.

Industrial candle production utilizes machinery to automate and streamline the process. Encapsulation machines quickly create perfectly molded candles. Larger kettles with motorized agitators can hold 50-100 pounds of wax to increase batch sizes. Conveyor systems transport drying candles through climate-controlled rooms. Labeling machines precisely apply stickers and packaging. All of this equipment requires significant capital investment but improves efficiency and quality control for high-volume production.

The scale of the candle-making operation determines the tools and equipment needed. Home hobbyists can start small with household items, while manufacturers invest in industrial machinery to support mass production and automation. The equipment directly impacts the quantity and consistency of candles able to be produced.

Product Variety

Candle manufacturers produce an enormous variety of candle styles, shapes, sizes, colors, and scents to appeal to different consumers and usage occasions. Some of the most common candle varieties include:

Shapes: cylindrical tapers, columns, pillars, votive, tealight, container candles, floating candles, sculpted shapes like numbers, letters, animals, flowers, holiday shapes, etc. [1]

Sizes: from small tealights to extra-large pillar candles over 12 inches tall and 6 inches wide. Votive candles are typically 1 to 1.5 inches tall. Pillars range from 3 to over 12 inches tall. Container candles range from 4 ounces to over 3 pounds. [1]

Colors: candles come in every color, often coordinated to match home decor or holiday themes. Popular colors include white, ivory, red, pink, purple, blue, green, yellow, orange, black, metallic, etc.

Scents: candles are often scented with essential oils and fragrances like floral, fruity, baking/food, woody, herbal, spicy, musky, fresh, or holiday themes. Unscented options are also available. [1]

Decorative vs Functional: some candles are designed purely for decorative appeal, like sculpted shapes. Others are functional for lighting, like taper and pillar candles. Container candles can provide both decor and fragrance. Floating candles add ambiance to pools, tubs, and tablescapes.

Quality Control

Manufacturing high quality candles requires careful quality control checks at multiple points in the production process. Key areas to focus on include:

Testing for safety – This involves verifying that wicks are appropriately sized for candle dimensions and burn safely without excessive soot or smoke. Wicks are tested to ensure they are lead-free as well. The burn temperature is checked to be within a safe range. Fragrance chemicals are reviewed for any restricted ingredients. Safety standards like ASTM F4002 should be followed (CANDLE QUALITY CONTROL. RAW MATERIALS TO FINISHED PRODUCT, 2011).

Consistency across batches – Batches should be consistent in appearance, fragrance, and burn quality. Color, texture, scent throw, and pool depth are compared across batches. Uniform molds and precise process controls help achieve batch consistency (The Art of Aromatherapy: An In-Depth Guide to Checking …, n.d.).

Meeting product specifications and standards – Finished candles are checked to ensure they meet size, shape, labeling, and packaging specifications. Burn times are verified to match product claims. Sensory and performance criteria outlined in product requirements are assessed. Any defective candles are rejected or reworked (The Ultimate Quality Control Checklist for Scented Candles, n.d.).

Distribution Channels

Candle makers have several options when it comes to distribution channels for selling their products, including:

Direct to consumer – Many candle makers sell directly to consumers through their own online stores, websites, social media, craft fairs, and other venues. Selling direct-to-consumer allows makers to retain more profit and control branding and messaging.

Wholesale – Selling wholesale allows candle makers to sell larger volumes of inventory at lower margins to retailers, gift shops, boutiques and other vendors who then resell to end consumers. Getting into national chains like Target, Walmart and grocery stores is very competitive but can provide high volume orders. (Source)

Retail – Many candle makers sell to independent gift shops, boutiques, craft stores, home decor stores, and other local brick and mortar retail outlets on a wholesale or consignment basis. Retail partnerships allow makers to reach local markets while retailers handle in-person sales and merchandising. Consignment arrangements require less upfront inventory investment.

E-commerce – Online marketplaces like Etsy, eBay, and Amazon Handmade are popular e-commerce channels, allowing makers to sell to a national audience. Candle makers can also leverage social media for driving traffic to their own e-commerce website. (Source)

Regulations

There are several regulations that candle makers need to be aware of when starting and running their business in Australia:

Product labeling – All candle products must be properly labeled according to regulations set by the ACCC. Important label information includes product name, business name, weight, ingredient list, hazard warnings if applicable, and contact information. Proper labeling helps ensure consumer safety. See the ACCC website for specific candle labeling requirements: https://www.accc.gov.au/business/treating-customers-fairly/product-safety

Business licensing – Candle makers must register their business name and may need additional state and local licenses depending on location and business activities. Common licenses include sales tax registration and commercial kitchen permits if selling food candles. Check with your state and local government to determine licensing requirements.

Safety standards – Workplace safety regulations must be followed, including proper handling of hot wax, chemical ingredients, and open flames. Proper ventilation, protective equipment, warning labels, and training help minimize risks. Review safety guides from WorkSafe Australia.

Environmental impact – Proper disposal of waste products, recyclable packaging materials, and avoiding harmful chemicals reduces the environmental impact of candle production. Being an eco-friendly business can be a competitive advantage.

Conclusion

In summary, while candle-making started out as a small homemade craft, it has evolved into a sizable industry producing a variety of candle products. Key points discussed include:

- Candle-making involves multiple production steps like melting, coloring, scenting, pouring, cooling, and packaging.

- Commercial manufacturers utilize specialized equipment for efficiency and scale.

- Quality control and safety regulations apply to protect consumers.

- Candles are distributed through both small artisanal shops and mass retailers.

Given the complex processes, regulatory oversight, and distribution networks involved, it’s clear that modern commercial candle production qualifies as a manufacturing business. The candle industry generates billions in revenue annually and continues to grow and innovate. While homemade candle-making remains a beloved DIY craft, the majority of candles people use today come from manufacturers producing candles as a core business. The industry provides employment, meets consumer demand, and brings enjoyment through its aromatic products.