How Much Wax Should I Buy For Candles?

Making candles at home can be a fun and rewarding hobby. Before getting started, it’s important to understand how much wax you’ll need to buy. The amount of wax required depends on the type of wax used, the container size, and other factors.

This guide will walk through the key considerations when determining how much candle wax to purchase. We’ll look at calculating the candle dimensions, estimating wax per candle, accounting for melted wax, wick requirements, testing, bulk discounts, storage, and recycling wax.

With some simple calculations, you can determine the right wax quantity to buy in bulk for your candle making. This will ensure you have enough materials on hand without overspending on unused surplus wax. Let’s explore the step-by-step process.

Calculate Your Candle Dimensions

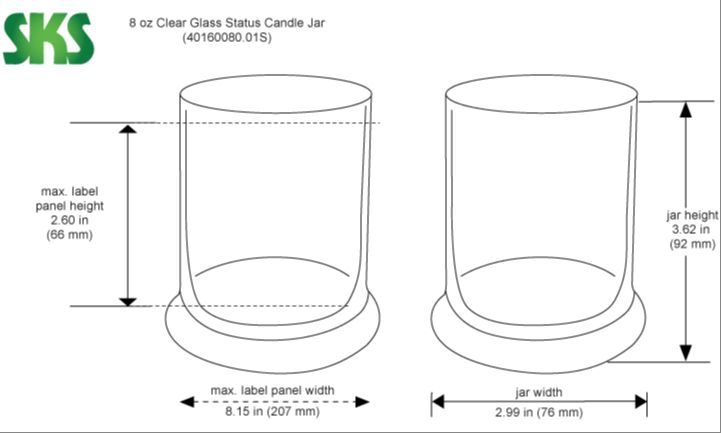

The first step in determining how much wax to buy is measuring the dimensions of your candle container. You’ll need to know the diameter and height of the container in inches or centimeters.

For example, a common size for a pillar candle is 4 inches (100mm) in diameter and 3 inches (75mm) in height (Source). Or if making a candle in a glass jar, measure from the base to the top opening.

Having the precise measurements will allow you to calculate the internal volume of the container and determine how much wax is needed to fill it.

Estimate Wax Needed per Candle

To determine how much wax you need for each candle, you’ll need to calculate the wax weight based on your candle dimensions. Here is a simple formula from Armatage Candle Company: Wax Weight = (Candle Volume in ml) x (Wax Density in g/ml). For example, if your candle holds 250 ml of volume and you are using a soy wax with a density of 0.90 g/ml, you would need 250 x 0.90 = 225 grams of wax per candle.

Another approach is to first calculate the volume of your container using basic geometry. For a cylinder shape, the formula is Volume = π x r2 x h. Then multiply the volume by wax density. For instance, a cylinder candle 3″ in diameter and 4″ high would have a volume of about 113 ml. With 0.90 density wax, you’d need around 102 grams of wax.

When estimating, round up slightly to account for wax that remains on the sides of the pouring pitcher. It’s better to have a little extra wax than not enough. Refer to manufacturer guidelines for the specific density of the type of wax you are using.

Factor In Wax Melting

When pouring candles, you’ll want to account for about 10-15% extra wax to allow for melting during the pouring process. As the wax heats up to a liquid state for pouring, some of the volume is lost as the wax changes from a solid to a liquid. According to industry experts, a good rule of thumb is to calculate about 10-15% more wax than your measurements estimate to account for this melting and volume loss.

For example, if your candle mold holds 20 oz of wax, you would want to buy about 22-23 oz of wax to ensure you have enough extra after melting to fill the mold properly. This helps prevent you from running short on wax mid-pour. The exact percentage may vary based on the type of wax used, as each has a different melting point. Paraffin wax melts at about 130-150°F while soy wax melts at 115-135°F (Source). The hotter the wax, the more volume is lost.

Testing different wax amounts is useful to dial in the right extra percentage for your specific wax and candle style. But including around 10-15% more wax than calculated is a good starting point to buy enough wax with the melting factor in mind.

Consider Wick Requirements

When choosing wick sizes, it’s important to consider the extra wax needed to properly anchor the wick.

Larger diameter wicks require more wax for anchoring than smaller wicks. Wicks need to be fully embedded into the wax to stay upright and burn properly. According to CandleScience, wicks should be anchored into the wax 1/2 to 1 inch deep depending on the candle diameter [1].

For example, a CD 12 wick has a diameter of 0.125 inches. To anchor this wick 1/2 inch deep, you need a minimum of 0.125 inches of extra wax multiplied by the wick length or circumference of the candle. Anchoring multiple wicks or tabs compounds the extra wax requirements.

When estimating your wax needs, remember to account for this extra amount to fully anchor the wicks before the wax pool reaches them during burning. Under-anchored wicks can fall over, tunnel, or bend to one side.

Buy Enough for Testing

When buying wax for your first few attempts at candle making, make sure to get extra wax for testing purposes. The first few candles you make likely won’t turn out perfectly, so testing and tweaking your process is key. Plan to make multiple test candles with small variations – different wick types, wax additives, scents, etc. Testing will allow you to dial in the right wax formula, wick, fragrance load, and vessel for your ideal candle.

Experts recommend getting at least double the wax you’ll need for your initial test batches (source: https://www.candlescience.com/learning/how-to-conduct-a-burn-test/). This ensures you’ll have enough wax on hand as you experiment. Keep detailed notes on each test pour to optimize future attempts. Don’t get discouraged if your first few candles have issues – testing and perfecting your process is part of the learning curve. With experimentation, you’ll be able to create quality, consistent candles.

Bulk Discounts

When buying larger quantities of wax at one time, you can take advantage of bulk pricing discounts. Most wax suppliers offer progressively lower per-pound pricing when you buy 10+ pounds, 25+ pounds, and 50+ pounds. The more wax you buy, the cheaper the per-pound price becomes.

For example, the base price for a 1-pound slab of soy wax may be $3. But that same wax may cost only $2.50/lb when buying 10+ pounds. And the price could drop to $2/lb at 25+ pounds. Buying a 50-pound box could reduce the cost to $1.50/lb or lower.

To maximize savings, estimate the total wax needed for your candle-making over the next 6-12 months. Then buy that entire supply at once to get the best bulk pricing. The wax won’t expire and you’ll lower your average material costs per candle. Just make sure to store it properly.

Store Properly

Proper storage of candle wax is essential for maintaining quality. Wax should be kept in a cool, dry location away from direct sunlight and heat sources. Ideal storage temperatures are between 10-21°C (50-70°F). Storing wax in the refrigerator is a good option, as long as it is allowed to return to room temperature before use. Freezing is not recommended as this can alter the wax’s structure. Keep wax in air-tight containers to prevent absorption of odors and dust. Dark storage containers help protect wax from UV light exposure. Storing different wax types separately prevents blending of scents or colors. With proper storage in a stable environment, most wax can last 6 months to a year before quality deteriorates. Following these tips will keep wax performing optimally and ready for candle making.

Recycle Leftover Wax

Instead of throwing away wax scraps after your candle making, consider reusing them to make smaller candles. Collect all the unused wax chunks, shavings, and drippings and melt them down into a reusable wax block. Cheesecloths or coffee filters can help strain out any wick pieces or impurities. The recycled wax can be poured into votive or tealight molds for mini candles. Just be sure to only mix wax of the same type so the melt point remains consistent. Refer to Candle Craft, A Complete Guide for more tips on recycling leftover candle wax.

Reusing wax is an eco-friendly practice that reduces waste and saves money on materials for future candle making projects. Small votive candles also make great gifts or decor using scrap wax.

Conclusion

When estimating how much wax to buy for candle making, it’s important to consider the complete candle dimensions, how much wax is needed per candle, wax melting allowances, wick requirements, and extras for testing. Buying wax in bulk can provide discounts but requires proper storage. Any unused wax can be recycled for future candle projects.

In summary, carefully measure the full candle design and volume to determine wax needs. Add at least 10% more wax to account for melting and drippings. Buy multiple wick sizes for testing to find the best fit. Allow for extra candles to test colors and designs. Store wax properly in cool, dry conditions. Buy bulk wax for the best price, but only if you can store excess inventory. Recycle all unused wax.

With some planning and calculations, you can determine the ideal wax amount to purchase for your candle making needs. This will provide enough wax to explore candle designs without buying an excess.