How Long Does It Take To Make A Candle At Candle Chemistry?

Candle Chemistry prides itself on handcrafting high-quality, custom candles for every occasion. Their artisanal candle making process involves everything from sourcing premium waxes and fragrance oils to hand-pouring each candle. At their workshop, they carefully craft each candle from start to finish.

The entire process of making a Candle Chemistry candle takes 1-2 days from gathering materials to quality control. Their team puts care into every step, taking the time needed to produce candles that meet their high standards. While most commercial candle manufacturers use automated equipment, Candle Chemistry relies on the skill of their candle makers to create candles by hand.

This article will provide an in-depth look at each step of Candle Chemistry’s candle making process. Understanding how much time, care, and attention to detail goes into each hand-poured candle gives customers insight into why these artisanal candles are special.

Gathering Materials

The first step in candlemaking is gathering the necessary supplies and materials like wax, wicks, fragrance oils, and containers. Popular types of wax used are paraffin, soy, and beeswax. Paraffin wax is derived from petroleum and makes up the majority of commercial candles. It’s relatively inexpensive and easy to work with. Soy wax comes from soybeans, is eco-friendly, and requires lower temperatures for melting. Beeswax is all-natural, has a beautiful honey aroma, and can be expensive.

There are various types of wicks like cotton, paper-cored, zinc-cored, and wood wicks. Cotton wicks don’t curl or bend well but are economical. Paper and zinc-cored wicks resist bending and remain upright as the candle burns. Wooden wicks create a crackling sound. The diameter and material determine how quickly the wick burns and absorb wax.

Candle fragrances are typically essential oils, infused oils, or synthetic fragrances diluted in a carrier oil. They provide candles with different scents. Top suppliers offer a wide range of complex fragrances replicating flowers, baked goods, fruits, spices, and more. Essential oils are natural but can fade quickly. Synthetic fragrances usually have better scent throw and longevity.

Candle vessels or containers come in different shapes, colors, and materials like glass, metal, plastic, wood, and ceramic. Glass containers allow the candle’s color to shine through. Tins are durable and cost-effective. Other options are jars, tumblers, teacups, votives, and more. The container’s opening width determines the appropriate wax volume and wick size.

Other miscellaneous supplies needed are thermometers, pour pots, scales, sticky mats, foil, labels, dyes, and molds.

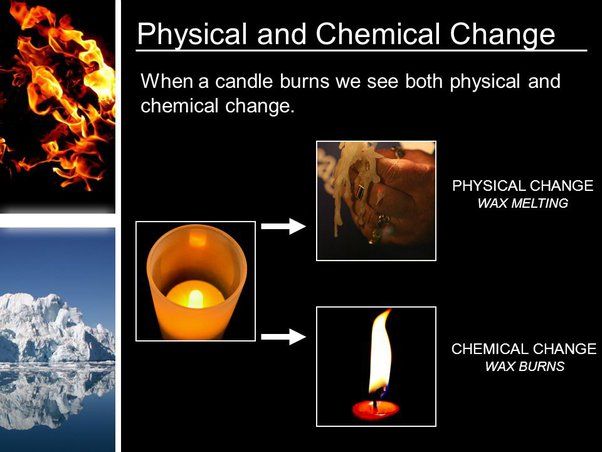

Melting the Wax

Melting the wax is a crucial step in candle making that requires the proper equipment to heat the wax to the ideal temperature. Most candle makers use a double boiler to gently melt the wax between 150-165 degrees Fahrenheit. The double boiler setup allows for a more even distribution of heat without scorching the wax [1]. Paraffin wax melts between 46-68°C, while soy wax melts between 49-82°C [2].

Having an accurate thermometer is critical to monitor the wax temperature. Overheating the wax can discolor it or alter the chemistry. Under-heating leaves solid chunks. With the right double boiler setup, melting 4-8 lbs of wax takes 45-90 minutes. Patience is key, increasing the heat too quickly risks burning the wax. The wax is ready when completely liquefied with no thick chunks remaining. Properly melted wax should pour easily and smoothly.

Adding Fragrance

At Candle Chemistry, we use a recommended ratio of 10% fragrance oil to wax to achieve the optimal scent. When adding fragrance to soy candles, it’s best to incorporate it when the wax is between 155-165°F according to candlemakingsupplies.net. This allows the fragrance to bind thoroughly with the wax before the pour. We carefully measure out the required amount of oils and make sure they are fully blended.

Preparing Wicks

One of the most important steps in candle making is preparing the right wick. The wick length should be around 1/4-1/2 inch longer than the height of the candle container to ensure proper burning. Centering the wick is also critical – if placed off-center, the candle may tunnel or have an uneven melt pool.

To prepare wicks, start by measuring and cutting cotton or wood wicks to the proper height for the candle container. Allow for extra length so the wick stays centered as the candle burns down. Use wick stickum or hot glue on the base of the wick and firmly press into place at the bottom center of the container. Hold for 30 seconds until the glue sets. Some wicks have metal tabs for easy centering. Allow the prepared wick to dry before pouring wax to ensure it stays in place.

The wick diameter also affects the candle burn. Larger jars need wider wicks, while smaller containers use thinner wicks. Testing different wick sizes to find the best fit for each candle is key. With the right wick preparation, the candle will burn evenly down to the bottom.

Pouring Candles

Once the wax is melted and fragrance is added, it’s time to pour the candles. The wax needs to be around 150-165°F for pouring. If it’s too hot, the fragrance may burn off or the wax may not set up properly. If it’s too cold, the wax can start to solidify before fully filling the candle vessel.

Candlemakers will carefully pour the wax into each vessel, leaving about 1/4″ of headspace at the top for the wax to shrink as it cools and contracts. The pour temperature gives a fluid wax that smoothly fills the vessel. Once poured, candles take about 1 hour to fully set up before moving on to inserting wicks.

Cooling is an important step, as pouring too soon can result in collapsed sides or a concave top surface on the finished candle. The ideal cooling setup has good airflow to accelerate the process, but not so much draft that it causes drips or ripples in the cooling wax.

Testing Candles

After the candles have cured for 24-48 hours, it’s important to conduct burn tests to evaluate their performance. Burn tests involve lighting the candle and allowing it to burn from the first to the last burn.

The goal of burn testing is to identify any issues such as tunneling, sinking, or excessive smoking so they can be addressed. According to Makesy’s “Candle Burn Testing 101” guide, the candle should burn evenly from edge to edge, maintaining a strong flame and wax pool without producing excess smoke. The wax pool should be a maximum of 1/2 inch deep.

If tunneling occurs, where the flame burns down the center and leaves wax around the edges, this is often due to an oversized or improperly placed wick. Makesy recommends using a smaller wick or trimming the existing wick as potential fixes. Sinking or small wax pools may indicate the wick is too small and can be addressed by using a larger wick.

It’s ideal to test candles for 8-10 hours to evaluate performance through the entire burn. This allows ample time to identify and fix any issues before the finished candles are sold or gifted.

Labeling & Packaging

Candle Chemistry focuses on high-quality labels and packaging to complete the finishing touches for each candle. All candles are labeled with the company logo, scent name, vessel type, and other details like burn time. Labels are printed on matte sticker paper that adheres smoothly to the vessels without wrinkling or bending (source).

For packaging, Candle Chemistry carefully wraps each candle to prevent damage during shipping. Pillar candles may be secured in cardboard candle sleeves, while candles in glass vessels are nested in bubble wrap. Tissue paper, crinkle cut paper, or shredded paper fills empty spaces to prevent jostling. Packaging must cushion candles without allowing them to shift during transit (source).

Candles shipped during summer months may also include ice packs to prevent melting. The packaging materials protect scent quality and vessel integrity until candles reach customers.

Quality Control

Before candles are ready to be sold, they undergo thorough quality control checks to ensure safety and quality. According to the Armatage Candle Company, some key aspects of candle quality control include:

- Appearance – Checking for any cosmetic defects in the candle labeling, jars, lids, or wax.

- Fragrance – Confirming the candle has the intended scent throw and aroma.

- Burn testing – Testing how the candle burns by lighting it in a safe testing area and observing flame height, mushrooming, sooting, and other attributes over time as cited here (https://armatagecandlecompany.com/blog/top-7-tips-for-efficient-candle-testing/).

- Wick testing – Observing wick performance like bending, drowned wicks, etc.

- Safety – Ensuring no sharp edges, stability when burning, appropriate warning labels, etc.

Quality controllers will reject any candles that do not meet specifications. Only once candles pass all checks are they approved for sale.

Total Time

The total time to make a candle from start to finish can vary depending on the type of wax, size of the candle, and required curing time. However, a general estimate based on making a soy wax candle in a basic glass container is as follows:

Gathering materials: 30 minutes

Preparing wax and pouring candles: 1-2 hours

Cooling candles: 2-4 hours

Curing candles: 1-2 weeks (Source)

Testing and labeling candles: 1 hour

So the total time to make and properly cure a soy wax candle is approximately 1 week and 2-5 hours. This does not include designing custom labels, packaging, or preparing to sell the finished candles. The process from start to finish for a handmade soy candle takes patience, but results in a high quality and long lasting product. With practice, the steps may start to go more quickly, but allowing for full cure time is vital.