Can You Use Zinc Wicks With Soy Wax?

Soy wax is a popular candle wax due to its versatility and eco-friendly nature. Soy wax candles first emerged in the early 1990s when candle makers were looking for a natural, sustainable alternative to paraffin wax. Since then, soy wax has become a staple in artisanal and commercial candle making.

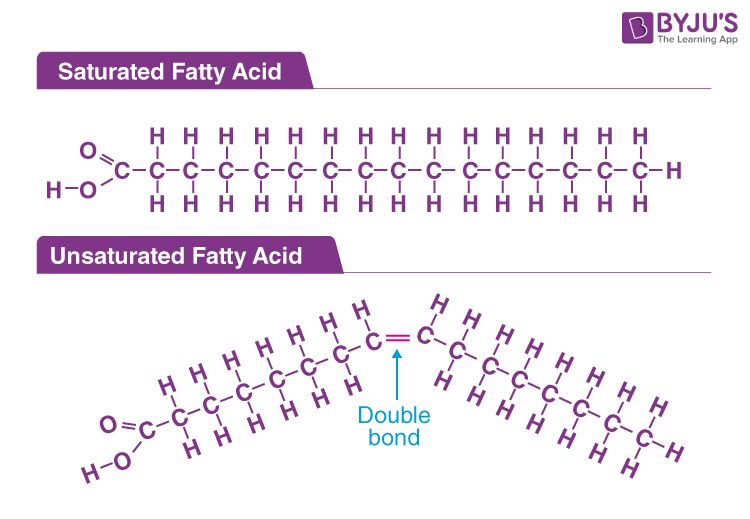

Soy wax is made from hydrogenated soybean oil, giving it a lower melting point than paraffin. This allows soy wax to hold fragrance oils well and produce a smooth pool when burned. Soy wax is also biodegradable and derived from a renewable resource. When properly formulated, soy wax candles can burn cleanly and have excellent scent throw.

One consideration when making soy wax candles is wick selection. The type of wick used with soy wax impacts the melt pool, burn time, and hot throw. Wicks designed for soy wax take into account the lower melting point and surface tension compared to paraffin. Popular options include eco-friendly paper and cotton core wicks, as well as zinc core wicks.

Soy Wax Overview

Soy wax is a popular candle wax made from soybean oil. It has become a common alternative to paraffin wax due to some advantages as well as disadvantages.

Some of the pros of using soy wax for candles include:

- Soy wax is made from a renewable and sustainable resource – soybeans – rather than petroleum like paraffin wax.

- Soy wax is biodegradable and considered more environmentally friendly.

- Soy candles typically have a lower melting point so they burn cooler than paraffin. This helps preserve fragrance (source: https://joetiehome.com/blogs/news/the-pros-and-cons-of-soy-wax-candles-what-you-need-to-know).

- The natural texture of soy wax can allow for a smoother candle surface and less frosting.

Some cons of soy wax to be aware of:

- Soy wax does not hold scent as strongly as paraffin wax. It may have a lighter scent throw (source: https://www.everythingdawn.com/blogs/news/34785665-the-pros-and-cons-of-soy-wax).

- The lower melting point also means soy candles do not burn as long as paraffin.

- Soy wax can be more expensive than paraffin.

- It’s sensitive to humidity and heat, making shipping and storage more difficult.

Overall, soy wax has trade-offs compared to paraffin but is a good option for eco-conscious candle making with its renewable nature and biodegradability.

Zinc Core Wicks

Zinc core wicks are made of cotton fibers braided around an inner zinc metal core (The Flaming Candle). The zinc allows the wick to maintain an upright, rigid shape that resists bending and curling as it burns. This provides excellent capillary action to draw wax up the wick and promote full melt pool development across the top of the candle. Zinc wicks are popular because they offer superior performance compared to regular cotton wicks.

The metal core makes zinc wicks stiffer than regular cotton. This allows them to stand up straight in pillar candles and remain centered in containers. The zinc also conducts heat into the wick for an even burn. Many candle makers prefer zinc core wicks because they create stronger scent throw and minimize issues like tunneling, poor wax pooling, and smoking (Hive and Honey Candle Co.).

Zinc core wicks are available in a range of sizes to suit different candle types, burn times, wax types, and desired flame heights. They can be used for tealights, votives, pillars, and containers. When paired with the proper wick size, zinc core wicks allow candles to burn clean and perform optimally.

Using Zinc Wicks with Soy Wax

Zinc core wicks can be an excellent choice when making candles with soy wax. Using zinc wicks provides several benefits:

Zinc wicks offer superior rigidity and stand up straight in the melted wax pool. Their stiffness helps maintain an even burn and prevents clogging or drowning of the wick as can happen with soft cotton wicks (Source: https://www.hiveandhoneycandleco.com/collections/zinc-core-wicks).

The zinc inner core burns hotter than cotton, allowing candles to melt and pool soy wax more efficiently. This helps maximize fragrance throw. The higher burn temperature also reduces mushrooming or charring at the wick top (Source: https://www.theflamingcandle.com/zinc-wicks/).

However, proper wick sizing is crucial when pairing zinc wicks with soy wax. An oversized wick can lead to sooting, while an undersized wick may struggle to melt the wax pool fully. Consulting manufacturer guidelines and testing different zinc wick sizes is recommended to find the ideal match for each soy wax blend and candle diameter (Source: https://www.craftserver.com/topic/42410-using-zinc-wick-with-soy-wax/).

With testing and proper wick selection, zinc core wicks can allow soy wax candles to burn cleanly and efficiently. Their stiffness helps maintain the wax pool and fragrance throw. But zinc wicks must be sized appropriately for optimal results.

Wick Sizing

Proper wick sizing is crucial when making candles with soy wax. Soy wax has a lower melting point and viscosity compared to paraffin wax, so it requires a larger wick to avoid issues like poor scent throw or tunneling.

As a general guideline, wicks one to two sizes larger than you would use with paraffin are recommended for soy wax candles. For example, if making a 4″ diameter soy wax candle, instead of a CD 10 or 12 wick typically used with paraffin, opt for a CD 14 or 16 wick 1.

When working with soy wax, it’s best to start testing with a wick on the larger end of the recommended range. You can always trim the wick down if needed. It’s more difficult to increase wick size on an existing candle. The type and amount of fragrance, as well as any dye or additives, will also impact your ideal wick size.

Refer to manufacturer recommendations and wick sizing charts as a starting point, but be prepared to test different wicks to find the best performance for your specific soy wax blend and candle design 2.

Wicking Test

Conducting a wicking test is crucial to ensure you are using the right wick size with soy wax. According to the video on Wick Testing, here are the key steps for testing wicks with soy wax:

- Prepare multiple candle vessels with different wick sizes, such as CD-5, CD-6, and CD-7.

- Melt soy wax and pour into each vessel around the wick, leaving 1/4″ room at the top.

- Allow candles to cure for at least 48 hours.

- Trim wicks to 1/4″ length.

- Light candles and observe the melt pool after burning for 4 hours.

- The proper wick size will produce a melt pool reaching the edges of the container after 4 hours.

- A fuller melt pool indicates the wick is too large, while a smaller pool means the wick is too small.

- The wick that gives the cleanest burn with no excess smoking or sooting is the best size.

As covered in the article from CandleScience, wicking tests allow you to zero in on the optimal wick for a soy wax candle before large scale production. Testing helps avoid poor scent throw, tunneling, and excess soot.

Troubleshooting

Soy wax is more temperamental than paraffin wax, and can be prone to some common issues if not handled properly. Here are some of the most frequent problems that arise when making soy candles and how to prevent or fix them:

Frosting

Frosting occurs when soy wax resolidifies too quickly after being poured into the container. It leaves a whitish film over the surface of the candle. To prevent frosting, avoid pouring soy wax above 175°F and make sure your container is warm before pouring (Candlescience.com).

Wet spots

Wet spots appear as oily marks on the top of the candle and occur when the wick is too large for the wax pool. Use a smaller wick or double wick to increase melt pool area and prevent wet spots (Candlecreations.co.nz).

Sinking

Sinking happens when part of the candle sinks down in the container as it cools and hardens. To prevent sinking, pour soy wax at 130-135°F and maintain an even pouring temperature (Candlescience.com).

Cracking

Cracking can happen if soy wax cools too quickly or unevenly. Avoid drastic temperature changes. Insulate your candle as it sets up to slow cooling. Pour soy wax no hotter than 135°F (Scentssoapsandcandles.co.uk).

Scent Throw

One of the main benefits of using zinc core wicks with soy wax is maximizing fragrance throw. Fragrance throw refers to how well a candle’s scent is dispersed into the surrounding area when burning. There are two components of fragrance throw – hot throw and cold throw.

Hot throw occurs when a candle is lit and the heat helps disperse the fragrance. Soy wax is known for having excellent hot throw capabilities when paired with the right wick. The zinc core of the wick promotes full melt pools that allow more fragrance oil to vaporize as the candle burns. This helps maximize hot throw with soy wax.

Cold throw happens when a candle is unlit. The soy wax absorbs fragrance oil and will release scent into a room even when not burning. Using an appropriate zinc wick size for your soy wax container shape and dimensions will allow for an ideal melt pool depth. This helps ensure maximum fragrance oil retention in the cooled wax for strong cold throw.

Testing different zinc wick sizes and monitoring melt pools is important to achieve excellent scent throw with soy candles. But pairing soy wax with a properly sized zinc wick will promote both hot and cold fragrance throw.

Candle Care

Proper care is important for getting the most out of your soy candles. Here are some tips for storing and burning soy candles:

For storage, keep soy candles out of direct sunlight and away from heat sources. Temperature fluctuations can cause frosting, sweating, and tunneling. Store candles in a cool, dry place between 50-80°F.

When burning soy candles, make sure to place them on a stable, heat-resistant surface away from drafts. Trim wicks to 1⁄4 inch before lighting to prevent smoking. Allow the wax pool to melt all the way to the edges before extinguishing the flame. This helps prevent tunneling. Do not burn candles for more than 4 hours at a time. Allow the wax pool to solidify completely before relighting.

To prevent wasting wax, place a candle snuffer or spoon over the flame to extinguish it. Never blow out a candle as this can spread hot wax. Soy wax can be prone to frosting, but this won’t impact performance. Gently re-melt the wax pool if needed. With proper care, soy candles can provide 50+ hours of burn time.

Sources:

https://www.ctrivercandles.com/candle-care.html

https://imolecandles.co.uk/blogs/news-1/how-to-care-for-your-soy-candle

Conclusion

In summary, zinc core wicks can be an excellent choice when making soy wax candles. They provide great flame control, help maximize scent throw, and give consistent burn performance. However, it’s important to test wick sizing thoroughly with every new soy wax blend and fragrance load to find the optimal setup. With the right wick size matched to your wax and oils, zinc wicks will help you achieve clean burns and excellent results with soy candles. The combination of zinc’s high heat conductivity and soy wax’s low melt point allows for full melt pool creation and fragrance diffusion. By following proper wicking techniques and testing for each candle variation, crafters can enjoy the benefits of zinc wicks with soy wax for stunning, long-lasting candles.