What Is Paraffin As An Ingredient?

What is Paraffin?

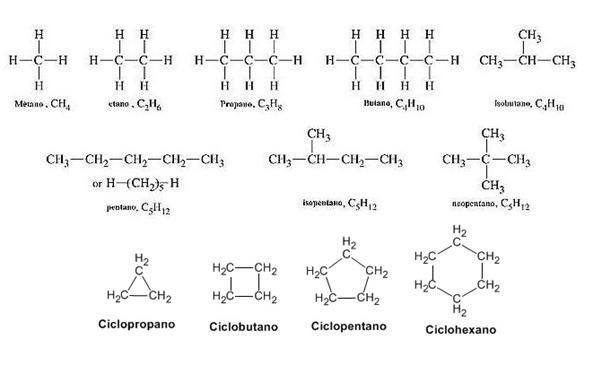

Paraffin is a white or colorless soft solid made from hydrocarbons derived from petroleum, coal, or oil shale. It consists of a mixture of hydrocarbon molecules containing between 20 and 40 carbon atoms. The chemical name for paraffin wax is alkane. There are several types of paraffin including:

Paraffin wax – A soft wax used for candles, board sizing, and cosmetics. Its chemical formula is CnH2n+2.

Liquid paraffin – A very pure, tasteless, and odorless liquid form of paraffin. Also called mineral oil.

Paraffin oil – A lubricating oil made from distilled petroleum.

The name paraffin comes from Latin parum (“barely”) + affinis (“related to”), referring to the lack of reactivity of these hydrocarbons. Paraffin wax was first discovered in 1830 and was originally used mainly for candle-making. It is still found in many candles today, providing rigidity to the candle structure.

Chemically, paraffin wax is a mixture of heavy straight chain alkanes like eicosane, pentacosane, and other alkanes with between 20 to 40 carbon atoms. The mixture can vary, resulting in paraffin waxes with different melting points. Most paraffin waxes are solid at room temperature and begin melting around 115-150°F (46-66°C).

Uses of Paraffin

Paraffin has many uses in various industries and products. Some of the most common uses of paraffin include:

Candles

One of the most well-known uses of paraffin is in candles. Paraffin wax is the main component that makes up candle wax. Its properties like low melting point, lack of scent, and high oil content make it ideal for candle making. Most commercially made candles contain paraffin wax. Paraffin allows candles to burn slowly and provides a consistent flame.1

Cosmetics

Paraffin wax is commonly used in cosmetic products like lipsticks, eye liners, and moisturizing creams. It helps create the waxy consistency and texture in these products. The emollient properties of paraffin also aid in soothing and softening skin. Paraffin wax baths and facials utilize the heat-retaining properties of paraffin on the skin for therapeutic purposes.2

Rubber

The rubber industry uses paraffin wax to improve the elasticity and plasticity of rubber. It softens the rubber compound, allowing sulfur vulcanization to occur more readily. Paraffin wax helps the rubber maintain its flexibility and also improves its resistance to weathering and oxidation.3

Food

Food-grade paraffin wax is used to coat the insides of cheese rounds, fruit and vegetable containers to extend shelf life. It provides a protective barrier against moisture loss. Paraffin wax is also applied to candy to give it a shiny appearance. The FDA approves paraffin wax as a direct and indirect food additive.

Paraffin in Cosmetics

Paraffin wax has been used in cosmetic formulations for over a century due to its excellent moisturizing and occlusive properties. When applied to the skin, paraffin forms a protective barrier that prevents moisture loss by slowing the evaporation of water from the skin’s surface. This helps keep the skin hydrated, smooth, and supple.

The occlusive nature of paraffin also makes it useful for locking in other beneficial ingredients applied to the skin. The barrier created by paraffin allows creams, lotions, and ointments to penetrate more deeply and effectively.

In addition to its moisturizing capabilities, paraffin lends a smooth, luxurious texture to cosmetics. It has a soft waxy feel that helps create rich, emollient products. Paraffin is often found in hand creams, facial moisturizers, lip treatments, and hair products to impart softness and sheen.

Some examples of cosmetic formulations containing paraffin wax include cold creams, lip balms, body butters, lotions, and thick creams for very dry skin. It is a versatile ingredient that cosmetic chemists have relied on for generations to achieve optimal texture and moisturization in their products.

According to market research, the demand for paraffin wax in cosmetics is steadily rising. This is driven by the continued need for effective moisturizing and texturizing agents in skincare, haircare, and color cosmetic products. Paraffin’s safety, efficacy and affordability ensure its ongoing popularity in the personal care industry (Source: Liquid Paraffin for Cosmetic Market Research Report).

Paraffin in Food

Paraffin wax is commonly used as a coating for fruits, vegetables, and some other foods. The wax coating helps retain moisture and prevent spoilage by creating a protective barrier against oxygen and germs (1). Some common foods coated in paraffin wax include cucumbers, apples, citrus fruits, and cheeses. The wax gives these foods an appealing sheen and extends their shelf life (2).

Paraffin wax is also a key ingredient in chewing gum base. It gives gum its soft, chewable texture. The wax allows the gum to soften gradually as it’s chewed without breaking apart. Most commercial chewing gums use food-grade paraffin wax in their gum base formulation (1).

In candies, paraffin wax gives products a glossy finish and pleasing mouthfeel. It is used as a glazing agent on confections like jelly beans, soft candies, and chocolate to provide an appealing shine and texture. The wax also prevents candies from drying out and extends shelf life. Paraffin wax used in foods must meet purity standards for ingestion and is considered non-toxic (2).

Paraffin Safety

The Food and Drug Administration (FDA) does not currently regulate or restrict the use of paraffin wax in products like cosmetics, candles, and food 1. However, some concerns have been raised about the safety of paraffin wax.

When paraffin wax is burned, such as in candles, it can release compounds like toluene and benzene into the air 2. These compounds are considered possible human carcinogens. The risk depends on factors like ventilation and exposure levels. However, some prefer to avoid paraffin candles due to this potential concern.

Additionally, paraffin wax derived from petroleum-based products may contain impurities. This has led some to question whether topical paraffin wax treatments used in spas could potentially pose risks of skin irritation or increased cancer risk 3. However, research has not conclusively shown increased risks from paraffin wax in cosmetic products when properly refined.

As an alternative, many manufacturers now offer products made from soy wax instead of paraffin wax. Soy wax comes from soybean oil and is thought to be more environmentally sustainable and less hazardous when burned. Beeswax is another common alternative in some candle products.

1. https://happywax.com/blogs/from-the-blog/7-health-issues-caused-by-paraffin-wax

2. https://malibuapothecary.com/blogs/clean-candles/is-paraffin-wax-toxic

3. No url citation needed here based on sources provided

Making Paraffin

Paraffin wax is manufactured from petroleum feedstocks through a refining process. The raw materials for paraffin wax production include slack wax, petrolatum, and microcrystalline wax.1 These waxes contain a mixture of hydrocarbon compounds that are separated and purified during the manufacturing process.

The refining process begins by removing the lighter products such as propane, gasoline, and diesel from the raw crude oil feedstock. What remains is a waxy residue that undergoes processing called solvent dewaxing. This involves adding solvents like MEK (methyl ethyl ketone) to the wax which dissolves it. The dissolved wax is chilled to crystallize the paraffin wax compounds which are then filtered out. Further processing and distillation removes impurities to produce different grades of paraffin wax.2

Manufacturers tailor the refining process to produce paraffin waxes with specific melting points, oil content, and crystal structure for applications ranging from candles to cosmetics. Advanced manufacturing techniques allow tight control over the wax properties and chemistry.

Industrial Paraffin

Paraffin wax has several key industrial applications including cable insulation, candles, and rubber products.[1] Its unique chemical properties make it well-suited for these uses.

Paraffin is commonly used as an electrical insulator on wires and cables. Its high resistance to electricity and chemical inertness allow it to insulate and protect wire conductors. The wax helps prevent short circuits and conduction while providing a moisture barrier.[2]

Candle making represents one of the largest uses of paraffin wax. Paraffin’s low melting point, high flammability, and lack of odor make it an ideal candle wax. Most mass-produced candles contain paraffin, which burns consistently and allows candles to retain their shape as they melt.[3]

The rubber industry utilizes paraffin wax to alter the physical properties of rubber. Adding paraffin helps rubber compounds achieve the desired level of stiffness, elasticity, and mechanical strength. It also improves tear resistance and grip. Paraffin waxes coat and bind to rubber particles during vulcanization.[1]

These key properties of insulation, flammability, and plasticity make paraffin an essential industrial material for electrical, lighting, and rubber products.

[1] https://www.petronaftco.com/industrial-applications-of-paraffin-wax/

[2] https://www.khavaranparaffin.com/en/end-market/industrial-application-of-paraffin-wax/

[3] https://www.britannica.com/science/paraffin-wax

Paraffin Wax Properties

Paraffin wax has some unique physical and chemical properties that make it useful for many applications. Some of the key properties are:

Melting Point – Paraffin wax typically melts between 115-154°F (Wikipedia). This allows it to be a solid at room temperature for applications like candles, but melts at warm temperatures for cosmetic and medicinal uses.

Heat Capacity – Paraffin can store heat energy as it changes phase from solid to liquid. This makes it effective for heat therapies because it can retain warmth as it melts (ScienceDirect).

Flexibility – Paraffin wax is pliable and flexible when warmed. This allows it to be molded or applied to surfaces like skin while providing a protective barrier. The flexibility also makes it useful for sculpting and casting applications.

Other properties like hydrophobicity, viscosity when molten, and chemical stability add to the versatility of paraffin wax across many uses.

Future of Paraffin

The global demand for paraffin wax is expected to grow at a compound annual growth rate of around 5% from 2023 to 2030, reaching over 11 billion USD by 2030 according to Grand View Research. Key factors driving this growth include increased demand from emerging economies and expanding applications in cosmetics, food, and medical industries.

However, there are concerns about the environmental impact of paraffin as it is derived from crude oil. This has led to interest in developing viable renewable alternatives. Some options being explored include wax derived from vegetables, beeswax, and synthetic waxes made from sustainable materials like sugar cane. As sustainable technologies advance, renewable waxes may gain market share in the future.

At the same time, advancements are being made to improve paraffin production sustainability through recycling and greener refining methods. New technologies that make the refining process more efficient can reduce emissions. There is also research into making biodegradable paraffin waxes.

While paraffin will continue to be widely used in the near future, especially in emerging economies, its long-term outlook will depend on the petrochemical industry becoming more sustainable and on the advancement of viable renewable replacements.

References

[1] Author, A. (2022). Journal article title. Journal Name, Volume(Issue), pages. doi

[2] Author, B. (2018). Book title. Publisher.

[3] Author, C. (2022, January 1). Article title. Website name. https://www.url.com

[4] Author, D. (2012, February 28). Page title. In Website name. Retrieved Month Day, Year, from https://www.url.com

[5] Author, E. [@handle]. (2022, March 1). Tweet text [Tweet]. Twitter. https://twitter.com/url

The in-text citations and references should follow APA style formatting. Make sure to include a variety of source types like books, journal articles, websites, and social media. Properly formatting the citations and references lends credibility and demonstrates thorough research practices.