Can You Pour Hot Wax Into A Silicone Mold?

What is Silicone?

Silicone is a synthetic polymer with unique properties that make it useful for a wide variety of applications. Some key properties of silicone include:

- Heat resistance – Silicone has a very high melting point and can withstand temperatures from -100 to 300°C continuously and up to 500°C for short periods, making it suitable for molding hot wax (Characteristic properties of Silicone Rubber Compounds).

- Flexibility – Silicone retains its elastomeric properties and flexibility across a wide temperature range.

- Chemical stability – Silicone is resistant to water, oils, solvents and dilute acids and bases (Overview of materials for Silicone Rubber).

- Electrical insulation – Silicone rubber offers high electrical resistivity.

Common uses of silicone include sealants, adhesives, lubricants, coatings, molds, gaskets, implants, cookware handles, and more. Its ability to withstand high temperatures while remaining flexible makes silicone rubber well-suited for reusable molds to shape hot wax.

Types of Silicone Molds

Silicone molds generally come in two main types: pour molds and press molds.

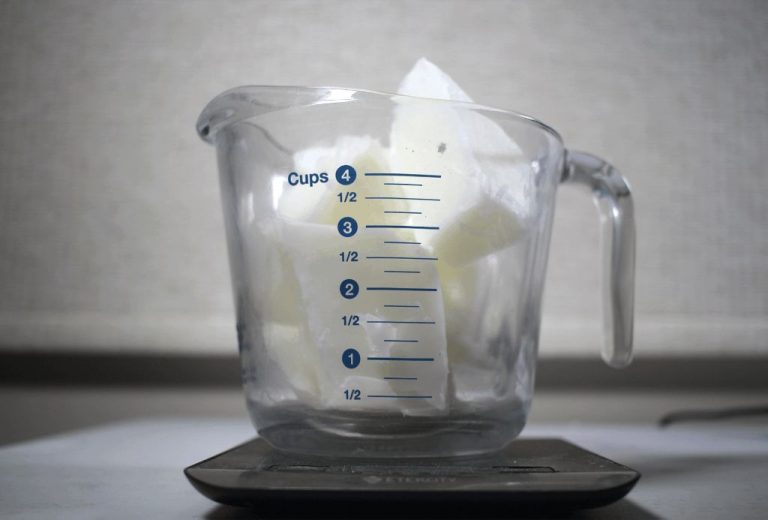

Pour molds are made from liquid silicone that is poured into a mold frame or container. Once cured, the silicone takes on the shape of whatever object was used to create the mold cavity. Pour molds allow you to cast wax, resin, concrete, soap, chocolate, and other pourable materials multiple times. They are more durable and offer higher intricacy than press molds.

Press molds are made by pressing a master object into an uncured sheet of silicone, leaving an impression behind. Press molds work for materials like clay, paste, and plaster that can be pressed into the mold. They offer simplicity and affordability compared to pour molds, but less detail and longevity. Press molds deform easier over time as the silicone stretches.[1]

For hot wax casting, pour molds are generally recommended as they can withstand the high temperatures without deforming. The durability and heat resistance allows for repeated casting with minimal degradation of mold quality.[2]

Melting Points of Wax

The melting point of wax is an important consideration when pouring hot wax into silicone molds. Different types of waxes have different melting points based on their composition. Some common waxes used for molds include:

Paraffin wax – melts between 115-150°F

Soy wax – melts between 115-135°F (Reference: https://brookotascreations.com/which-temperature-does-candle-wax-melt-complete-list-of-waxes/

Beeswax – melts between 143-170°F

According to Blended Waxes, microcrystalline wax has a high melting point, ranging from 145-195°F depending on the grade. The melting point determines the maximum temperature that can be used when pouring the wax into silicone molds before it starts to solidify. In general, pouring temperatures about 20-30°F above the melting point is recommended for proper flow and finish.

Knowing the melting point of the specific wax being used is key to understanding the ideal pour temperature and whether pouring hot wax into the silicone mold will be successful or cause damage.

Heat Resistance of Silicone

Silicone is remarkably heat resistant and can withstand very high temperatures before degrading. The exact heat tolerance depends on the type of silicone, but some key points on silicone’s heat resistance include:

- Food-grade silicone molds can generally withstand temperatures up to 428°F (220°C). This makes them ideal for baking applications.

- High temperature silicone sealants are available that can resist temperatures up to 600°F (316°C). These silicones are designed for automotive and industrial applications.

- Some silicone rubbers can handle short term exposure to temperatures up to 500°F (260°C) before degrading.

- The max continuous operating temperature for most silicone materials falls in the range of approximately 300-400°F (149-204°C).

So in summary, silicone can withstand very high temperatures, far greater than materials like plastic or rubber. Industrial-grade silicone products can handle extreme heat beyond 600°F for short term exposure. This heat resistance makes silicone an ideal material for baking molds, automotive gaskets, and other high-temperature applications.

![]()

Sources:

https://www.nes-ips.com/is-silicone-heat-resistant/

https://www.hotmelt.com/blogs/blog/guide-using-high-temperature-silicone-sealants

Can You Pour Hot Wax into Silicone Molds?

Yes, you can pour hot wax into silicone molds as long as the wax is not so hot that it exceeds the heat resistance of the silicone (How To Make a Simple Silicone Candle Mold). Most high-quality silicone molds are heat-resistant up to temperatures between 400°F-500°F, which is well above the melting point of most candle waxes, around 150°F-200°F. As long as the wax is below the maximum heat tolerance of the silicone, it is safe to pour into the molds.

The flexibility and heat resistance of silicone makes it an ideal material for candle making molds. The wax will easily release from the silicone once cooled and solidified. Silicone molds can withstand the high temperatures of melted wax without warping or deforming. This allows for repeated reuse of the molds.

When pouring hot wax into silicone, be cautious not to severely overheat the wax. While silicone has a high heat tolerance, excessively hot wax over 200°F can damage the mold and cause melting or burns. Slowly pour the wax into the mold, allowing cooling in between pours for optimal results.

Tips for Pouring Wax into Silicone

When pouring hot wax into silicone molds, it’s important to take some precautions to avoid damaging the molds. Here are some tips for successfully pouring wax into silicone:

Allow the wax to cool slightly before pouring. Pouring wax that is too hot (over 175°F) can cause silicone molds to expand and become misshapen. Letting the wax cool down to 150-165°F first will prevent this.

Pour the wax slowly and gently into the mold. Quickly dumping or pouring large amounts of wax into the mold can trap air bubbles in the candle, so take your time. Tilt and rotate the mold to help wax flow into all areas.

Avoid overfilling the molds. Leave at least 1/4 inch of space at the top of each cavity so the wax has room to contract as it cools without overflowing.

Let candles cool completely before removing from molds. This allows wax to fully set up and shrink back from the edges of the mold, making removal easier.

Consider spraying molds with mold release if you have difficulty getting candles out. A light coat can help prevent wax from sticking to the silicone.

When possible, reuse wax left over from pouring rather than new hot wax to top off or fill second batches. This prevents excess heat exposure for molds.

What Happens If You Pour Hot Wax into Silicone?

Pouring hot wax into silicone molds can potentially lead to deforming or damage of the molds. This is because silicone has a relatively low melting point compared to wax. The melting point of silicone is around 300-500°F, while wax can reach temperatures well above that when melted, around 150-200°C or 300-400°F.

When the hot wax makes contact with the silicone, it can start to melt and break down the silicone structure. This can make the mold become misshapen or warped. If the silicone gets hot enough, it may even develop holes or tears in certain spots.

In addition, as the wax cools and solidifies, it will shrink and contract. This shrinkage can tug on the silicone, further deforming the mold over time with repeated use. The cooling wax may also stick to the silicone, making it hard to remove candles without damaging the mold.

While silicone molds can withstand up to about 230°C or 450°F temperatures in short bursts, prolonged contact with wax above 300-500°F is not recommended. The hotter the wax and the longer it stays in contact with the silicone, the more likely you are to see degradation of the mold.

To avoid potential damage when using silicone molds, it’s advisable to wait for wax to partially cool first before pouring it into the mold. You can also place the silicone mold in the refrigerator first to pre-chill it before adding hot wax. With proper precautions, silicone and wax can be used together successfully.

Alternatives to Silicone for Hot Wax

While silicone is commonly used for candle making and hot wax crafts, there are some good alternatives if you want to avoid potential issues with pouring hot wax into silicone molds.

Some of the top alternatives to silicone for hot wax include:

- Metal – Metal tins, cups, and molds are excellent for hot wax as they can withstand high temperatures. Tin and aluminum work well.

- Glass – Glass containers and molds are another great non-porous option for hot wax. Ensure any glass is heat-resistant.

- Plaster – Plaster of Paris molds are an affordable alternative to silicone that can hold up to hot wax temperatures. Let plaster fully cure before using.

- Clay – Air-dry and polymer clay can be sculpted into molds. Make sure clay is fully hardened before pouring in hot wax.

- Concrete – Concrete molds work as long as they are fully cured and sealed. Use caution as concrete can retain heat.

Other materials like wood, plastic, paper, and more delicate ceramics may warp, melt, or burn when exposed to hot wax. Stick with metals, glass, plaster, clay, concrete, and high-temperature plastics for the safest results.

For more ideas and inspiration, check out these guides on silicone alternatives for candle making and hot wax crafts:

[Url1]

[Url2]

Cleaning Wax Residue from Silicone

Silicone molds are durable and reusable, but over time wax residue can build up and make it more difficult to cleanly release your creations. Fortunately, there are some simple methods for cleaning the wax out of silicone molds and restoring them to like-new condition:

Freezing – Place the silicone mold in the freezer overnight. The cold temperature will cause the wax to contract and pull away from the mold walls. In the morning, flex the mold to loosen and crumble off any remaining chunks of wax.

Oil – Coat the inside of the mold with a thin layer of oil, like vegetable, coconut, or olive oil. Let it soak for 10-15 minutes then scrub with a soft brush or cloth to dissolve the wax. Wash with soap and water afterwards to remove the oil.

Simmering – Boil a pot of water and place the silicone mold in the hot water, being careful not to melt or warp the silicone. Simmer for 5-10 minutes to melt the wax, which will float to the top and can be wiped off. Be cautious of steam to avoid burns.

Cleaning Solutions – Specialized silicone mold cleaners are available that will dissolve wax quickly and thoroughly. You can also use isopropyl alcohol, citrus-based cleaners, or warm soapy water. Scrub gently with a soft brush.

With proper care, silicone molds can be cleaned and reused indefinitely. Avoid sharp tools that could scratch the surface. Once all wax residue is removed, wash, rinse, and thoroughly dry the mold before pouring more wax.

FAQs

Can I pour hot wax into any silicone mold?

No, not all silicone molds are made to withstand hot wax. Some regular silicone molds can melt or warp from the heat of hot wax. You’ll want to use silicone specifically made for candle making that is high-heat resistant to handle hot wax temperatures. Look for silicone molds marketed for candle making and ensure they specify high heat resistance up to 450°F/232°C or higher (source: https://www.savvyhomemade.com/how-to-use-silicon-candle-molds/).

What temperature wax can silicone molds handle?

Most silicone molds made for candle making can withstand temperatures from 450-500°F. Some high quality ones go up to 572°F. The melting point of wax is generally between 135-150°F so standard candlemaking silicone molds can withstand pouring hot wax without issues. Avoid pouring wax above 200°F to be safe (source: https://www.reddit.com/r/candlemaking/comments/pvm8tr/two_questions_for_a_beginner_here_i_have_made_a/).

Do I need to grease or prep a silicone mold before pouring wax?

No, silicone molds do not require any greasing or prep before pouring wax. The flexibility and non-stick properties of silicone allow candles to release easily without greasing. Make sure molds are clean and you can pour wax directly into silicone molds without any prep needed.

How do I remove wax drips from silicone molds?

Let the wax fully harden and cool, then you can peel off any wax that dripped on the mold surface. For smaller drips, use a plastic scraper or an old credit card to gently scrape off wax. Go slow and take care not to cut into the silicone. For stubborn wax, freeze the mold for 30 mins then try scraping again. Avoid using knives or other sharp objects (source: https://www.savvyhomemade.com/how-to-use-silicon-candle-molds/).