What Material Is Used To Hold Up An Incense Stick?

The use of incense has a long history, dating back thousands of years. Incense was used in ancient cultures for spiritual and religious purposes, to honor deities, and in important ceremonies. The burning of incense was an integral part of many ancient religions and belief systems across different civilizations including Ancient Egypt, India, China, and the Americas.

The earliest recorded use of incense comes from Ancient Egypt, where it was used in burial rituals and tribute ceremonies as early as the 5th dynasty, around 2400 BCE. The Ancient Chinese used incense as part of ancestor worship from at least 500 BCE. In India, incense was mentioned in the Vedas, ancient Hindu scriptures that were composed between 1500 and 1000 BCE. The Indians also used incense widely in Ayurvedic medicine.

Materials Used

The most common materials used to make incense sticks are bamboo, wood, and paper.

Bamboo

Bamboo is one of the most popular materials for incense sticks due to its natural hollowness that allows it to hold the incense mixture well. It also burns evenly and is inexpensive, sustainable, and renewable (Agarwood/Oud incense stick materials).

Wood

Various types of wood, like sandalwood, cedar, or pine, are commonly used for incense sticks. Wood burns slowly and evenly, allowing the incense aroma to be released gradually. The wood grain also helps the incense mixture adhere. Soft woods like pine are more affordable, while fragrant woods like sandalwood add their own aroma (Agarwood/Oud incense stick materials).

Paper

Paper can also be used, often layered with bamboo or wood. Thin paper allows the incense smell to come through easily. Paper is lightweight and inexpensive, though may burn faster than wood or bamboo (Agarwood/Oud incense stick materials).

Bamboo

Bamboo is a common material used to hold up incense sticks due to its natural properties. According to H&E – Cedar – Bamboo Incense 20 sticks, bamboo produces “minimal smoke” and is created with “the natural blessings of the earth.” Bamboo is lightweight yet sturdy, allowing it to hold incense sticks upright while burning without breaking. It’s also inexpensive and renewable, as bamboo is one of the fastest growing plants on earth.

The porous structure of bamboo enables it to easily absorb fragrances, allowing the incense aroma to come through more strongly. And since bamboo itself has very little scent, it doesn’t interfere with the intended fragrance. This makes it an ideal material for premium-quality incense.

However, bamboo can be susceptible to mold if not properly dried. It also burns relatively quickly compared to dense woods. This means incense sticks using bamboo may not last as long as those using hardwoods.

Wood

Some of the most common types of wood used to make incense sticks include palo santo, sandalwood, cedar, pine, and agarwood.

Wood provides a natural material that can burn steadily and produce pleasant smoke. Hardwoods like cedar and sandalwood are commonly used. Softwoods like pine are also utilized, but may not burn as evenly. Wood types differ in their scent – sandalwood has a warm, sweet aroma, while pine offers a fresh, evergreen fragrance.

Palo santo is a fragrant wood native to South America that has traditionally been used for cleansing and purification. It has a woody, spicy scent and produces a calming effect. The aromatic resins in palo santo make it an excellent material for incense sticks.

Wood also allows for custom combinations of scents by mixing woods like sandalwood and cedar. Carefully sourcing quality natural woods results in aromatic, non-synthetic incense sticks.

Paper

Paper is a common material used to hold up incense sticks. There are several types of paper that can be used including rice paper, mulberry paper, and bamboo paper. Rice paper and mulberry paper are thin and lightweight, allowing the incense aroma to emit easily as the stick burns. However, rice paper and mulberry paper can be fragile for handling and shipping the sticks. Bamboo paper is made from bamboo fibers so it is more durable while still being thin (https://shop-vestige.com/collections/home-candles-incense).

The pros of using paper for incense sticks are that it burns evenly, allows the fragrance to emit well, and is lightweight. The cons are that paper can be fragile to handle and may break easily compared to wood or bamboo. Manufacturers need to find the right balance of paper thickness and durability for their incense products ().

Other Materials

In addition to bamboo, wood, and paper, some manufacturers also use alternative materials like plastic to create incense sticks. Plastic incense sticks emerged as an option in recent years as plastics became more widely available and cost-effective. The most common plastics used for incense sticks are:

- Polypropylene – a very versatile plastic that can be rigid or flexible. It’s known for its high tensile strength.

- PVC – polyvinyl chloride plastic which is inexpensive and easy to manufacture with.

- PET – polyethylene terephthalate, commonly used for plastic bottles. PET incense sticks tend to be very lightweight.

The use of plastics for incense sticks is controversial. Some view plastic incense as a creative way to reuse plastics that would otherwise end up in landfills. However, others argue that burning plastic releases toxic fumes. There are also concerns around proper disposal and recycling of plastic incense sticks after use.

Manufacturing Process

The manufacturing process for incense sticks varies slightly depending on the main material used. Here is an overview of how each material is made into incense sticks:

Bamboo: Bamboo sticks are harvested and cut to size. The sticks are then dried to remove moisture. Next, the sticks are dipped into a fragrant paste or powdered incense material to coat them. After dipping, the sticks are left to dry again before packaging.

Wood: Thin wooden sticks are cut from sustainable wood sources. The sticks are dried and may be sanded smooth. Like bamboo, the wood sticks are dipped into scented pastes or incense powders. Once coated, the sticks dry and cure before being bundled and packaged.

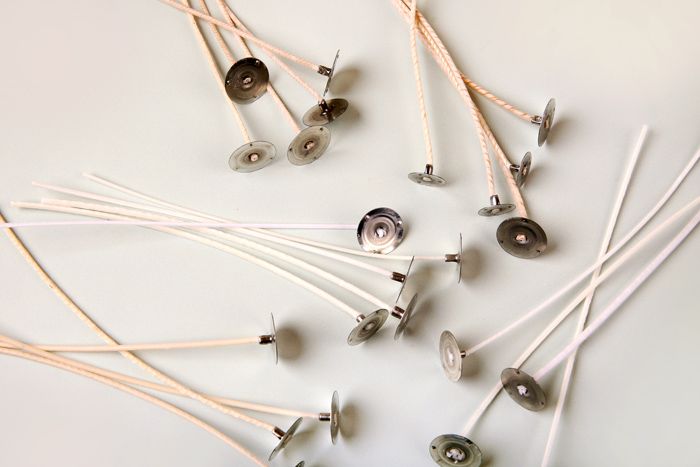

Paper: Paper is rolled tightly around a thin stick or wire frame to create the incense stick shape. The paper rolls are then similarly coated in scented materials by dipping or spraying. After drying, any wire frame is removed before packaging the paper incense sticks.

Other: Materials like cotton rope and flower stems may also be used as incense stick bases. These organic materials are coated in scented paste or powder and left to dry before use.

Overall, the manufacturing process involves cutting and shaping the base material, applying scented incense coatings, drying the sticks, and then packaging the final incense products.

Sources:

https://www.news18.com/business/watch-how-incense-sticks-are-made-in-india-8656565.html

Environmental Impact

The materials used to manufacture incense sticks can have varying impacts on the environment. Bamboo and wood are generally considered more sustainable materials, as they can be renewable resources when properly managed. However, unsustainable harvesting of trees and bamboo can lead to deforestation and habitat loss.

According to research, some major incense producing regions in India have experienced concerning levels of deforestation due to high demand for materials like bamboo and wood. This has disrupted local ecosystems and biodiversity. There are efforts underway to promote more sustainable sourcing of these materials, such as through bamboo plantations and certified wood programs. However, challenges remain in tracing complex global supply chains.

Paper and pulp based incense sticks also have some environmental impacts from the forestry, pulping, and manufacturing processes. However, sustainably sourced paper can have lower impacts compared to unsourced wood harvesting. Some incense companies are investing in research and development of alternative plant-based materials to reduce dependence on wood.

Overall, conscientious sourcing of renewable, sustainably managed forestry materials can help minimize the environmental footprint of incense production. But further work is needed to improve transparency and truly sustainable practices across global supply chains.

Source: https://markwideresearch.com/incense-sticks-agarbatti-market/

Aesthetics

The material used to make incense sticks can significantly impact the aesthetic experience of burning them. Different materials burn at different temperatures, which affects the rate of scent dispersion. Additionally, some materials are more porous than others, allowing the incense aroma to infuse into the stick itself.

Natural materials like bamboo and wood tend to burn slower and cooler than synthetic materials like paper. This slower burn allows the incense scent to disperse gradually over a longer period of time. Bamboo and wood also readily absorb incense oils, releasing the aroma steadily as they burn.

In contrast, materials like paper and pulp burn faster and hotter. This quick burn can cause the incense scent to disperse too rapidly or become overwhelmed by smoke. Non-porous materials like paper do not hold the fragrance as well either. The scent tends to stay concentrated on the surface rather than permeating the entire stick.

Ultimately, natural materials like bamboo and wood provide the most balanced and pleasant incense burning experience. Their ability to control the burn rate and fully absorb the incense oils results in a long-lasting, consistent scent dispersion.

Conclusion

To summarize, incense sticks are commonly made from materials like bamboo, wood, and paper due to their ability to slowly burn and hold fragrance. The manufacturing process involves drying, shaping, and applying fragrances through methods like soaking and rolling. While aesthetically pleasing, incense sticks can have negative environmental impacts due to the burning process. However, there is room for future innovation in creating more sustainable incense products.

Going forward, we may see more environmentally-friendly incense sticks made from materials like beeswax or essential oils that don’t create as much smoke pollution. There is also potential for technology like electronic diffusers to mimic the scent experience of incense in a cleaner way. Overall, manufacturers will need to balance tradition with innovation to create incense products that can continue delighting our senses for generations to come.