What Are Candle Lite Candles Made Of?

Candle-lite is one of the oldest and most well-known candle brands in the United States. The company has been making candles since 1840 when English settler Thomas Emery started selling candles door-to-door. Over the years, Candle-lite has grown into a major manufacturer of scented candles, producing a wide variety of candle products today.

Candle-lite sells candles in various shapes and sizes, from taper and pillar candles to container candles. They offer candles in an array of scents, from fruity and floral to spicy and woodsy. Some of their most popular candle lines include their flagship Original Scented Pillars, Nature’s Oil soy candles, and Scented Tapers.

In addition to scented candles, Candle-lite also makes unscented candles, tealights, and votives. Their products are sold through various retailers as well as through their website and catalog. Known for their long-burning, clean-burning, and colorful candles, Candle-lite aims to provide quality candles at an affordable price point.

Wax

Candle-lite uses a blend of paraffin wax and soy wax to create their candles according to the company website. Paraffin wax is a petroleum byproduct that provides candles with a high melting point for better burn time. Soy wax is made from soybeans and is often promoted as more natural and environmentally friendly (Candle-lite Company, n.d.). The soy wax helps make the candles cleaner burning.

The combination of paraffin and soy creates a stable candle wax that holds scent nicely. Candle-lite offers candles in a range of wax blends from 100% paraffin to 100% soy wax. The traditional Candle-lite blend uses paraffin as the primary wax with 10-20% soy wax added. Specialty candles may contain beeswax or other natural waxes as well (Candle-lite Company, n.d.).

Wicks

The wicks used in Candle-lite candles are typically made from braided cotton (Wick Type | Candle-lite Company). Cotton makes a good wick material because it’s soft and flexible, which allows it to bend as the wax pool forms while burning. The braided structure gives the wick stability and prevents it from falling over into the melted wax.

Candle-lite also offers candles with specialty wooden wicks, which produce a signature crackling sound as they burn (Wooden Wick Candles). These wicks are made from natural wooden materials like bamboo, beechwood, and maple. The wood absorbs more wax as the candle burns, preventing mushrooming at the tip of the wick. Wooden wicks require a larger wax pool to burn properly compared to regular cotton wicks.

Scents and Dyes

Candle-lite uses both natural and artificial scents and dyes in their candles. For their natural scents, they extract oils directly from plants, flowers, fruits, and herbs to capture authentic aromas like lavender, jasmine, and sandalwood (https://www.candle-lite.com/collections/essential-elements). These natural oils provide therapeutic benefits and a clean, pure fragrance.

Artificial scents are created in laboratories by combining chemical ingredients to replicate natural smells. These synthetic fragrance oils allow Candle-lite to offer a wider variety of scents, like fruit punch, vanilla cake, and clean linen. However, some consumers prefer natural ingredients over artificial ones. There are also concerns that synthetic fragrance chemicals could be irritants for people with sensitivities (https://www.candle-lite.com/).

For coloring, Candle-lite uses FDA-approved liquid dyes to tint their candles in various shades. Some dyes are nature-derived from mineral or plant sources, while others are synthetic. The dyes produce an even color throughout the wax without affecting the candle’s burn quality.

Molds

Candle-lite makes candles in a variety of shapes and styles using different molds. Some of their most popular molds include:

Jars – Candle-lite offers round glass jars in sizes ranging from 4oz to 22oz. Popular jar styles include their Everyday jar, Apothecary jar, and Heritage Collection jar. Jars allow the wax to be seen and provide a classic candle look (Source).

Tumblers – These cylindrical plastic containers come with lids and range in size from 3oz to 20oz. Tumblers allow the candle to be portable and reusable (Source).

Pillars – Pillar candles come in round, square, hexagonal, and octagonal shapes, ranging from 4″ to 12″ tall. They provide a timeless, elegant look (Source).

Votives – These small candles are 1.5″ tall and come in cups, cubes, and rounds. They’re designed for tea lights and create ambient lighting (Source).

Novelty Shapes – Specialty molds create fun candle shapes like wine bottles, apples, leaves, spiders, and more for seasonal décor (Source).

Manufacturing Process

Candles are made through a multi-step manufacturing process that involves melting wax, adding dyes and fragrances, placing wicks, and pouring wax into molds or containers. The basic steps are:

First, solid blocks of wax are loaded into a large melting vessel and heated to temperatures between 150-170°F to liquefy the wax. Paraffin wax, a byproduct of petroleum refining, is commonly used in commercial candle making. Other waxes like soy, beeswax, and palm wax may also be used.

Once the wax is completely melted, dyes and fragrances are added and incorporated evenly into the wax. Liquid or powder dyes are used for coloring the wax. Fragrance oils specially formulated for candle making are added for scent. Essential oils can also be used.

Wicks are carefully positioned in the middle of each candle mold or container. The wick must be straight and centered to ensure proper burning. Popular wick materials include cotton, paper, and wood.

The hot liquid wax is then carefully poured into each mold or container, around the centered wick. Molds allow multiple identical candles to be produced efficiently. Containers like glasses and jars allow a variety of shapes and styles.

Once poured and slightly cooled, the candles are allowed to fully harden and cure. Curing improves burn quality. The finished candles are then packaged and made ready for shipping and sale.

Automated production lines allow large-scale manufacturing of candles efficiently. However, artisanal candle makers often handcraft candles in small batches using many of the same time-honored production steps.

Testing & Quality Control

Candle manufacturers follow rigorous testing and quality control procedures to ensure their products meet safety standards and perform as expected. Key areas of testing include:

Safety and Burn Testing

Candles must undergo extensive safety testing to evaluate fire hazards and burn characteristics. According to ASTM International standards (ASTM F2417) https://candles.org/industry-standards/, candles are tested for properties like flame height, wiggle room, warpage, carbon deposits, and more. Testing labs like Intertek https://www.intertek.com/products-retail/candle-testing/ ensure candles meet requirements for smoke density, burning rate, stability, overheating, and other safety factors.

Candles must pass burn tests to verify they self-extinguish within a certain time frame if tipped over or left unattended. Wicks are evaluated to ensure proper capillary action and reduce emissions like soot. These stringent tests help minimize fire hazards and risks to consumers.

Packaging

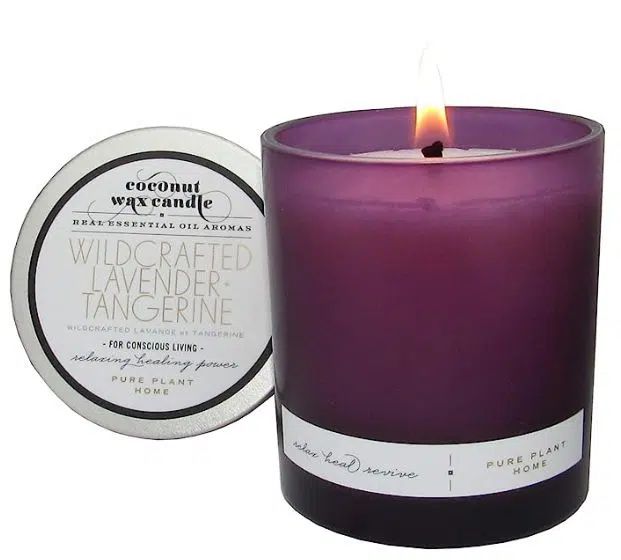

Candle Lite candles come packaged in either glass jars or metal tins. The most common jars are made from soda-lime glass, which is inexpensive and widely available. According to Flushpackaging, glass jars allow customers to see the candle itself while also providing an elegant container to display. Glass jars come in many shapes, sizes, and colors to fit different needs. The metal tins are commonly made from rolled steel and coated in enamel paint for decoration and to prevent rusting. Tins allow for more custom shapes and designs, provide added protection for shipping, and can be reused after the candle is finished. Some customers may prefer the reusable nature and vintage look of a tin, while others like seeing the candle itself in a clear glass jar.

Environmental Impact

Candle-lite has made sustainability a core part of its business practices and manufacturing processes for years. The company uses natural soy wax, cotton wicks and pure essential oils in many of its candle lines (https://www.candle-lite.com/). This allows candles to burn cleaner and more sustainably. Candle-lite also recycles all of its wax scraps during production, reducing waste (https://candleworld.eu/en/producers/candle-lite-company-1499164286.html).

In 2022, Candle-lite announced new sustainability goals to further reduce its environmental impact. This includes transitioning to recycled and recyclable packaging, investing in renewable energy at its facilities, and offsetting carbon emissions from operations and shipping (https://www.candle-lite.com/pages/faq). The company aims to be carbon neutral by 2025. With 182 years of candle-making experience, Candle-lite is well positioned to show leadership in sustainability.

Conclusion

In summary, Candle Lite candles are made from a variety of key ingredients. The main component is paraffin wax, which provides the fuel for the candle. Paraffin is a petroleum-based wax that offers an affordable and effective burning material. The wicks in Candle Lite candles are typically made from braided cotton for a consistent burn. Fragrance oils and dyes are added for scent and color. The candle ingredients are poured into molds in the manufacturing process to form the candle shape. Candle Lite conducts quality testing to ensure safety and performance. The finished candles are packaged in containers with brand labelling.