Why Is Soy Wax So Expensive?

Soy wax is a vegetable wax made from the oil of soybeans. After harvesting, the beans are cleaned, cracked, de-hulled, and rolled into flakes. The soybean oil is then extracted from these flakes and hydrogenated to convert the oil into a solid wax.

Soy wax was first developed in the 1990s as an alternative to paraffin wax, which is a petroleum byproduct. It quickly gained popularity among candle makers and enthusiasts because it is a renewable, sustainable resource that also has beneficial properties like a lower melting point and being cleaner burning.

Compared to paraffin wax derived from fossil fuels, soy wax is more eco-friendly. However, the complex production process required to create the hydrogenated soy wax makes it significantly more expensive than paraffin.

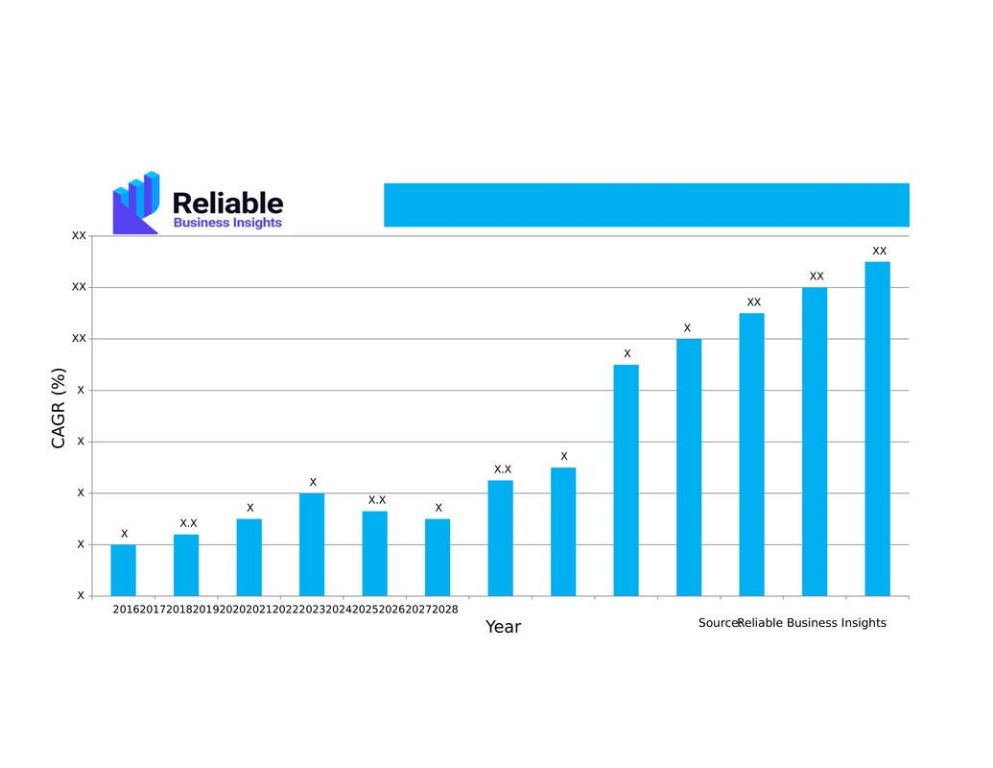

Increasing Demand

There has been steady growth in demand for soy wax over the past decade, especially from the candle making industry. According to a recent market report, the global soy wax market size was USD 5780.4 million in 2022 and is projected to touch USD 10795 million by 2031, exhibiting a CAGR of 7.2% (source: https://www.businessresearchinsights.com/market-reports/soy-wax-market-106933). The majority of this demand comes from the use of soy wax to produce scented candles. Soy wax is often preferred over paraffin wax for candle making because it is a renewable and natural resource that produces less soot when burned. The soy wax scented candle market in particular is expected to see substantial growth in coming years, as demand for natural and eco-friendly candles increases (source: https://medium.com/@serenaframi/soy-wax-scented-candle-market-size-growth-forecast-2023-2030-e29cd6f8aea4). This steady rise in demand, especially from the candle industry, is a major driver behind the higher prices of soy wax.

Limited Supply

Only a small percentage of soybean crops are used to produce soy wax. Soybeans grown in the United States have many uses, including food products, animal feed, and biodiesel production. According to the United Soybean Board, less than 2% of the soybean crop is used to make soybean oil for industrial purposes like candle wax production. With so many competing uses for soybeans, only a limited supply is available for making soy wax.

The majority of soybeans are processed into soybean meal and soybean oil. The soybean meal is largely used to feed livestock, while the soybean oil is made into cooking oil, biodiesel fuel, or used in processed foods. Only a fraction of the soybean oil is further refined into ingredients like soy wax through an intensive process called hydrogenation.

With many applications for soybean oil, soy wax producers have restricted access to the raw materials they need. This limited availability leads to higher prices for food-grade soy wax compared to more abundant products like paraffin wax.

Complex Production Process

Producing soy wax involves an extensive, multi-step process to extract and refine the wax from soybeans. First, the raw soybeans are cleaned, cracked, flattened into flakes, and subjected to a solvent extraction process to separate the soybean oil. The oil then goes through a degumming process to remove impurities. To extract the wax, the refined soybean oil undergoes winterization, where it is cooled to filter out some saturated fats. The winterized oil is then hydrogenated, a chemical process that converts liquid oils into solid fats. The hydrogenated oil is then deodorized and bleached to further purify the wax. This complex series of production steps requires significant investments in specialized equipment and energy to extract and refine the wax to meet quality standards for candle making.

According to one source, “The creation of soy wax requires a number of complicated steps including cleaning the soybeans, extracting the oil mechanically or with solvents, refining, bleaching, hydrogenating and then deodorizing the oil.” (Source)

High Energy Costs

Producing soy wax requires significant energy inputs at multiple stages of the process. First, growing soybeans is an energy-intensive agricultural process. Soybeans require fertilizer, irrigation, and machinery for planting, tending, and harvesting the crops. Fuel and electricity are consumed during each phase of crop production. According to the USDA, soybean production requires over 2000 BTU per pound of energy inputs.

After harvesting, soybeans must be transported to processing facilities. Running trucks, trains, and barges to move soybeans across the country also consumes large amounts of diesel fuel and electricity.

Finally, once at processing plants, soybeans are put through various mechanical and chemical processes to extract soybean oil and process it into wax. The equipment involved – including boilers, hydrogenation reactors, centrifuges, etc. – requires substantial energy to operate. The processing phase can account for over 50% of the total energy usage in soy wax production.

With energy prices constantly fluctuating, the high energy intensity of soy wax production contributes to the final cost paid by candle makers and consumers.

Labor Costs

Soy wax candle making requires considerable human labor at various steps of the production process, from creating wax blends and adding fragrance to pouring, cooling, and packaging finished candles.

Unlike paraffin wax candles, which can be fully automated, soy wax is more delicate and requires careful hand pouring and monitoring to ensure proper results. According to candle makers on Reddit, it takes around 5-10 minutes of hands-on labor to make each individual soy candle, excluding setup and packaging time (https://www.reddit.com/r/candlemaking/comments/25do5d/what_do_you_charge_for_labor/).

In addition, soy wax shrinks more than paraffin as it cools, so makers often have to top off and re-pour candles multiple times. Trimming and smoothing the tops is also frequently done by hand. The extra time and care required at each step drives up the human labor costs substantially.

According to pricing calculators, labor can account for 25-50% of the total cost of making soy candles, making it one of the most significant expenses (https://www.candlescience.com/how-to-price-your-candles/). This labor-intensive process is a key factor behind the higher prices of soy candles compared to paraffin.

Transportation Costs

A significant factor driving up the cost of soy wax is the high transportation costs involved in getting soybeans from farms to processing facilities. Soybeans are primarily grown in the Midwest region of the United States, as well as in Brazil and Argentina. However, many soy wax processing facilities are located elsewhere, necessitating long distance transportation.

According to the USDA, in the first quarter of 2023, the average transportation cost for exporting soybeans from Brazil was $76.96 per metric ton (source). This accounted for over 13% of the total landed cost. Soybeans and soy wax must be shipped long distances via rail, truck, barge and ocean vessel from the soybean farms to the processing plants. Each transportation handoff adds costs. Ultimately, these high transportation costs get passed onto the end consumer of soy wax.

Similarly, transportation costs account for a significant portion of the total cost for soy wax manufacturers in the United States. The United Soybean Board estimates transportation and storage costs add 2.5 to 3 cents per bushel of soybeans (source). Over long distances, these costs add up and contribute to the high price of soy wax.

Packaging Costs

Soy wax is typically sold in retail packaging like plastic buckets, cardboard boxes, or plastic bags (https://www.fillmorecontainer.com/candle-supplies/soy-candle-wax.html). This protective packaging allows consumers to easily store and transport large quantities of wax. It also provides an appealing retail presentation for crafters and candle makers shopping in stores or online.

These packaging costs contribute significantly to the higher price of soy wax compared to paraffin wax. Paraffin wax is often sold in bulk without added packaging since it does not need as much protection for shipping and storage. Soy wax’s tendency to sweat and change consistency based on temperature variations means it requires more safeguarding (https://www.candlescience.com/wax/soy-wax/). Retail packaging provides this protection but adds expense.

Many soy wax suppliers offer bulk packaging options without retail boxes or buckets. However, the wax must still be put into some type of protective bagging. The packaging and shipping expenses account for a portion of the higher soy wax pricing, especially for small hobbyists and businesses purchasing retail-packaged wax in low quantities.

Branding & Marketing

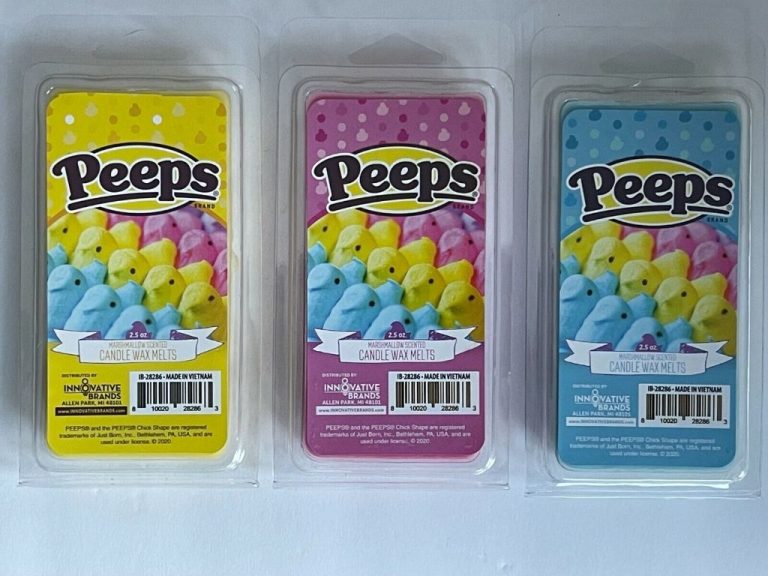

Soy candle brands must invest significantly in branding, marketing and packaging to build consumer recognition and loyalty. Unlike generic paraffin candles, artisanal soy candles rely on distinct branding to convey their premium status and justify their higher retail pricing. According to this source, startups costs for branding essentials like logos and brand stories can easily exceed $500-$1,500.

Once a soy candle brand achieves wide consumer recognition and loyalty, retailers are able to command much higher wholesale and retail pricing for their products. Consumers readily pay a premium for brands they know and trust. Strong branding signals exceptional quality and craftsmanship that consumers value highly when selecting soy candles. As such, the high upfront investments into marketing and branding enable the significantly higher profit margins soy candle makers enjoy compared to generic paraffin varieties.

Comparison to Paraffin Wax

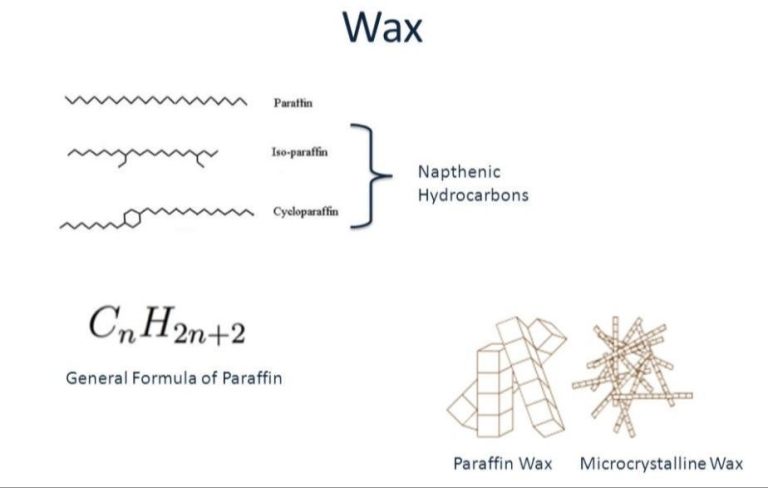

One of the main reasons soy wax is more expensive than paraffin wax is that paraffin wax production is less resource-intensive. Paraffin wax is a petroleum byproduct created during gasoline production, so the raw materials are relatively inexpensive. The production process is also simpler and requires less energy than growing and processing soybeans (https://simplenesscollection.com/en-us/blogs/news/soy-wax-candle-vs-paraffin-candle-whats-the-difference). Soybeans need to be grown, harvested, processed, and refined to extract the soy oil used to produce soy wax. Paraffin wax, on the other hand, is separated from crude oil during the refining process so no additional steps are needed.

The renewable and natural source of soy wax comes at a premium cost compared to paraffin from fossil fuels. While many consumers prefer soy wax for environmental and health reasons, the complex agricultural and production system makes it much more expensive per pound than paraffin wax (https://www.slatkinandco.com/blogs/the-slatkin-summary/soy-wax-vs-paraffin-wax-which-is-better). The cost difference can make soy wax candles and products two to three times higher in price than paraffin-based versions.